Method for purifying tantalum powder

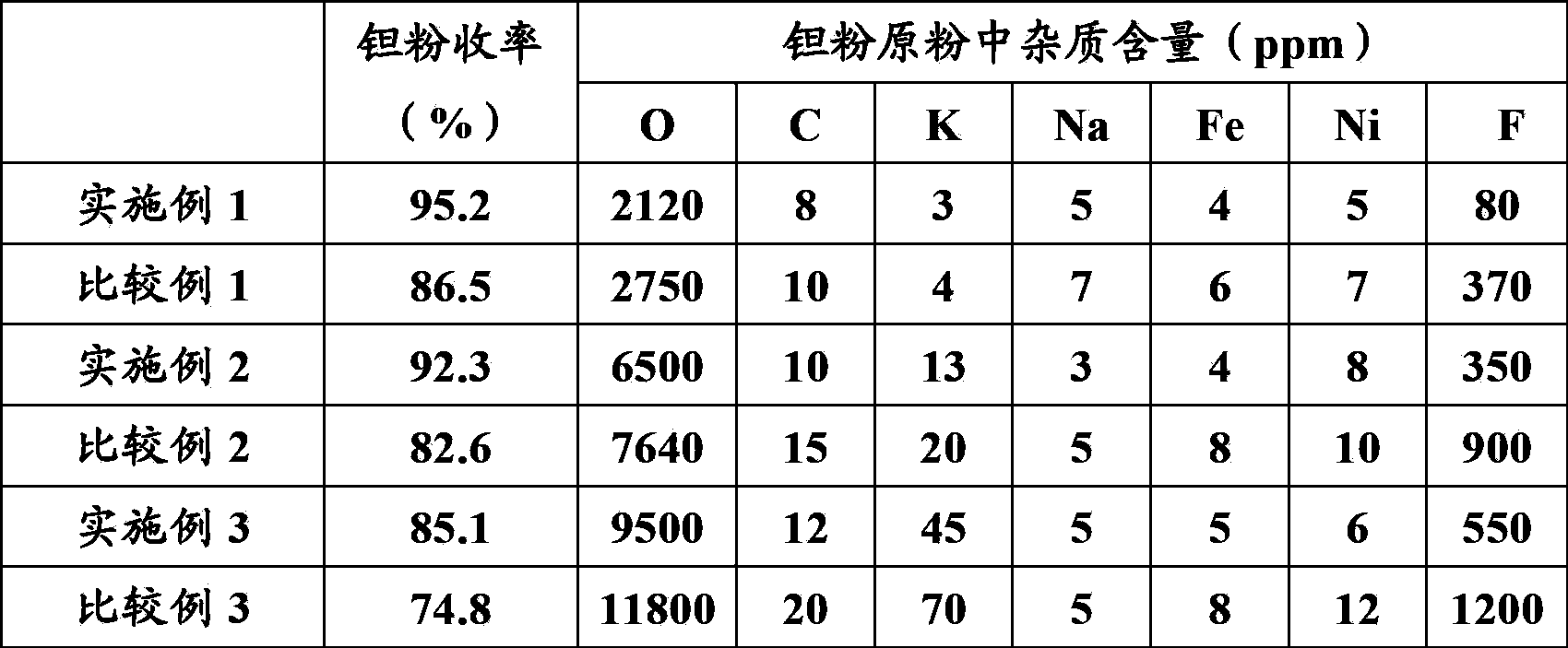

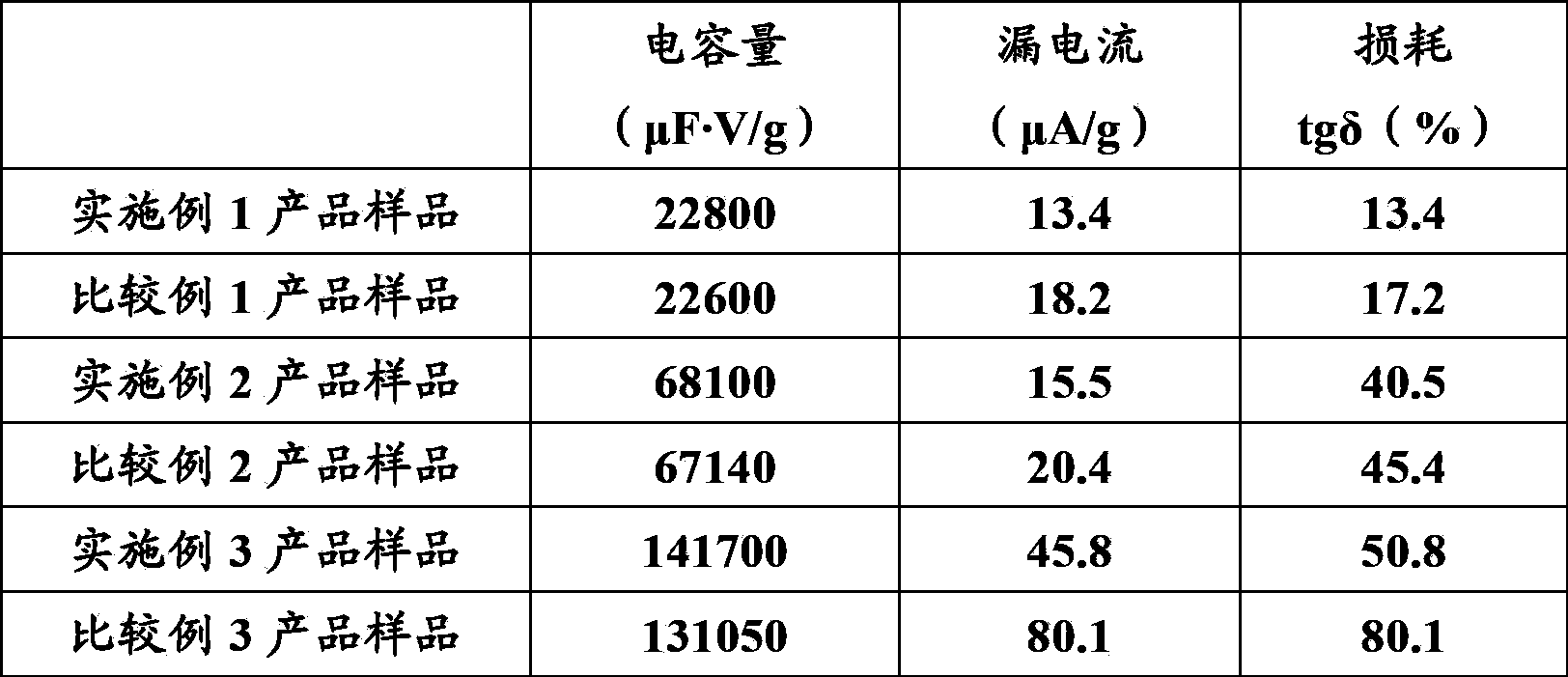

A technology of tantalum powder and alkali metal, which is applied in the field of purifying tantalum powder from a mixture containing tantalum powder, alkali metal and alkali metal halide, which can solve the problem of high content of K and Na in tantalum powder, reduced yield of tantalum powder, and difficulty in cleaning Eliminate other problems, achieve the effect of high purity of raw powder, high yield of tantalum powder, and low leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] First, a mixture containing tantalum powder, alkali metal and alkali metal halide is provided by the following method: 100kg of sodium chloride (NaCl) is charged into the reaction vessel, heated to 900°C, and 100kg of potassium fluorotantalate ( K 2 TaF 7 ), then add about 30kg of liquid metal sodium, keep warm at 900°C for 2 hours, cool to room temperature to obtain a mixture of tantalum powder, alkali metal and alkali metal halide in the form of condensed block, take out the condensed block from the reaction vessel, Break into small pieces less than 20mm, and divide into two evenly.

[0042] Then, add the hydrochloric acid aqueous solution that 3 / 4 tank pH value is 4.0 in the filter washing tank, add the first small piece in the filter washing tank and wash, guarantee that the aqueous solution liquid level is higher than the reaction material surface more than 10cm in the washing process; In the first 1 hour of washing, use pH test paper to detect the pH value of th...

Embodiment 2

[0051] First, the mixture containing tantalum powder, alkali metal and alkali metal halide is provided by the following method: put a mixture of 100kg potassium chloride (KCl) and 100kg potassium fluoride (KF) in a reaction vessel, heat to 900°C, and then Add 100kg potassium fluorotantalate (K 2 TaF 7 ), then add about 30kg of liquid metal sodium, keep it warm at 900°C for 1 hour, and after cooling to room temperature, take out the reaction product from the reaction vessel, that is, a mixture of tantalum powder, alkali metal and alkali metal halide in the form of condensed block, and crush it into small pieces smaller than 20mm, and divide the crushed material into two parts equally.

[0052] Then, add 3 / 4 tank of hydrochloric acid aqueous solution with a pH value of 4.0 to the filter washing tank with stirring paddle, turn on the stirring paddle, and the rotating speed of the stirring paddle is 10 rpm; add the first small piece into the filtering tank for washing , in the f...

Embodiment 3

[0061] First, the mixture containing tantalum powder, alkali metal and alkali metal halide is provided by the following method: put a mixture of 150kg potassium chloride (KCl) and 150kg potassium fluoride (KF) in a reaction vessel, heat to 880°C, and then In the reaction vessel, add 30kg potassium fluorotantalate (K 2 TaF 7 ), then add about 10kg of liquid metal sodium, keep it warm at 880°C for 0.5 hours, and after cooling to room temperature, take out the reaction product, that is, the condensed block, from the reaction vessel, break it into small pieces smaller than 20mm, and divide the broken material into two share.

[0062] Then, add 3 / 4 tank of hydrochloric acid aqueous solution with a pH value of 4.0 in the filter washing tank, add the first small pieces into the filter washing tank for washing, and ensure that the aqueous solution has no reaction materials during the washing process; in the first 1 hour of washing In the washing tank, check the pH value of the aqueo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com