Sealing assembly structure of glass material and metal for rocket engine

A rocket engine and glass material technology, applied in the direction of rocket engine devices, machines/engines, mechanical equipment, etc., can solve the problems of small compression of expanded graphite pads, increased fastening force, glass breakage, etc., and meet the requirements of ensuring shock resistance , Guarantee sealing requirements, simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

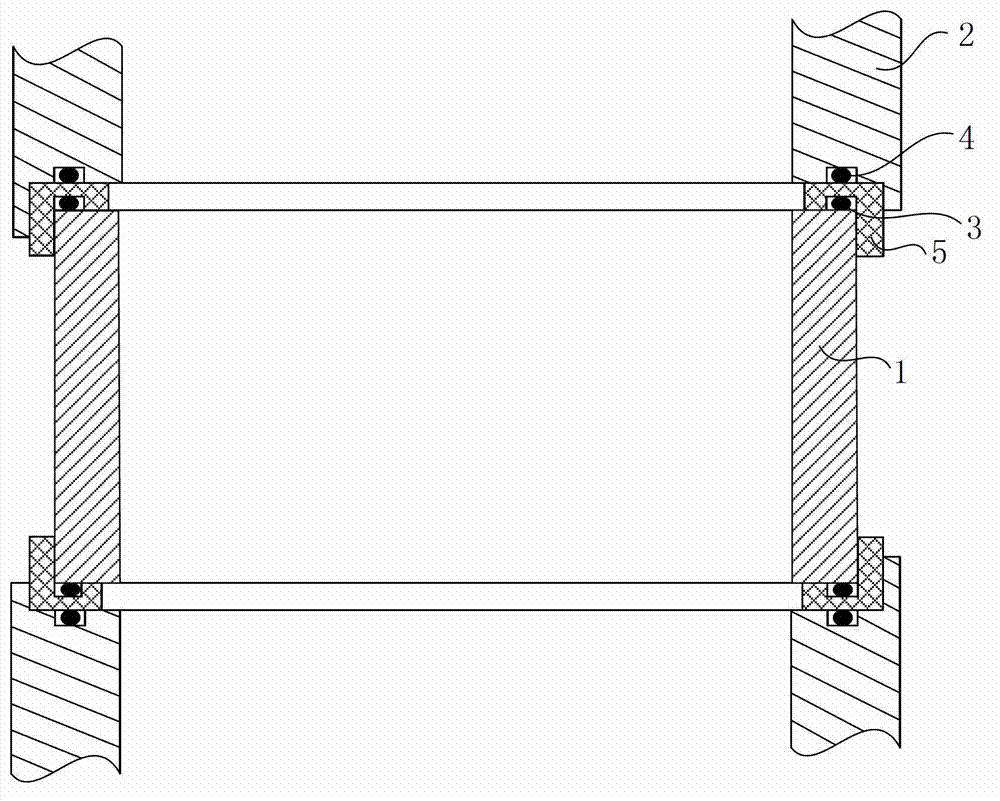

[0018] The present invention is used for the sealing structure between the glass material and the metal of the rocket engine, and realizes the sealing between the end of the glass cylinder section and the end of the metal cylinder section, including the glass cylinder section, the metal cylinder section, the seal ring A, the seal Ring B and gasket. Among them, the sealing ring A is an O-ring made of nitrile rubber material, which is set on one end of the cylinder section of the combustion chamber made of transparent glass material; the sealing gasket is a ring structure made of polytetrafluoroethylene material, and has a diameter Width up. The sealing pads are arranged on the end faces of both ends of the glass cylinder section, and are located above the sealing ring A to cover the sealing ring A. There is an annular groove A on the inner side wall of the gasket, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com