Radiator fan wind scooper

A radiator fan and air guide cover technology, which is applied in the direction of machines/engines, engine cooling, liquid fuel engines, etc., can solve the problems of reduced cooling efficiency of radiators, turbulent flow at the corners of radiator fan air guide cover, etc., to achieve Reduced manufacturing cost, improved heat dissipation efficiency, and long manufacturing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

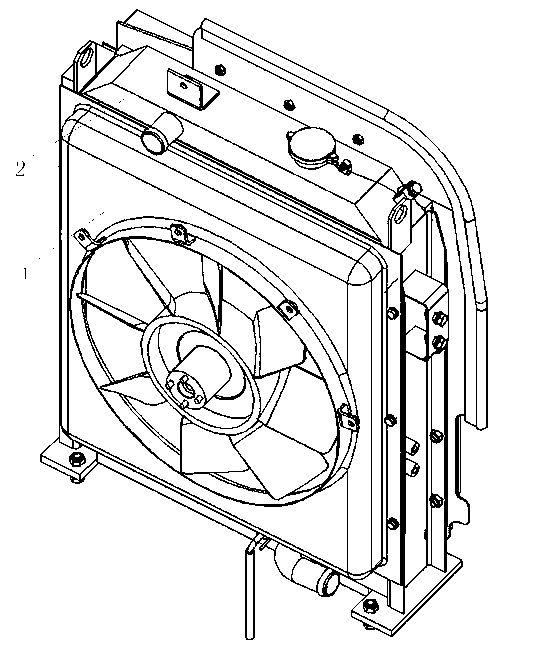

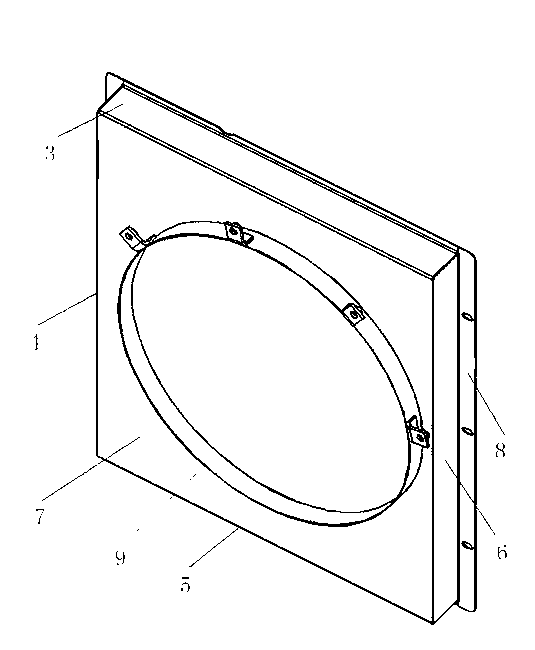

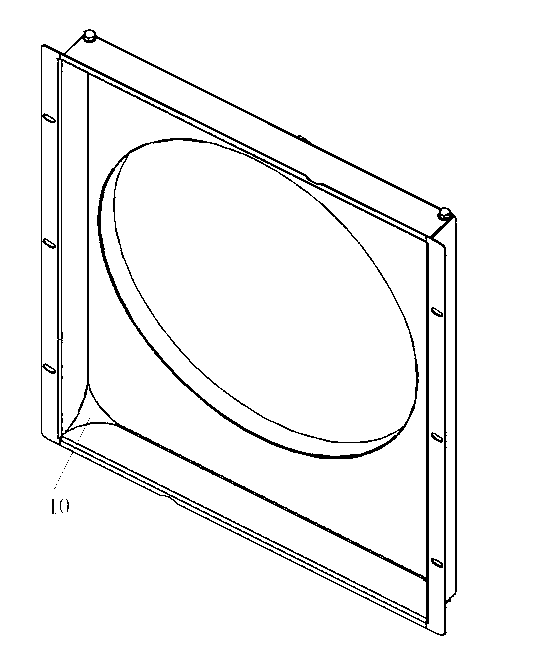

[0017] Such as figure 1 , figure 2 , image 3 In the radiator fan air guide shown, four rectangular side plates 3, 4, 5, 6 and a square bottom plate 7 with ventilation holes in the middle are welded together, and welded to the installation frame 8 of the air guide 1, A thin plate is formed into a circle as large as the middle hole of the main board 7 to form a ring 9, and the ring 9 is welded to the middle hole of the main board 7 to form the outlet of the air guide cover 1; 10 is installed on at least two of the four inner corners of the air guide cover 1, and finally the assembled air guide cover 1 is installed on the radiator 2.

[0018] The manufacture method of deflector block 10:

[0019] 1) Casting: direct casting of the guide block 10 by using a casting method;

[0020] 2) Stamping: use the stamping method to open the mold to punch out the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com