Solar battery module and manufacturing method thereof

A technology of solar cells and electrodes, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of ineffective photoelectric conversion efficiency of solar cell modules, multiple working hours, and consumption, and achieve optimal photoelectric conversion efficiency, save machine costs, The effect of reducing the area ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

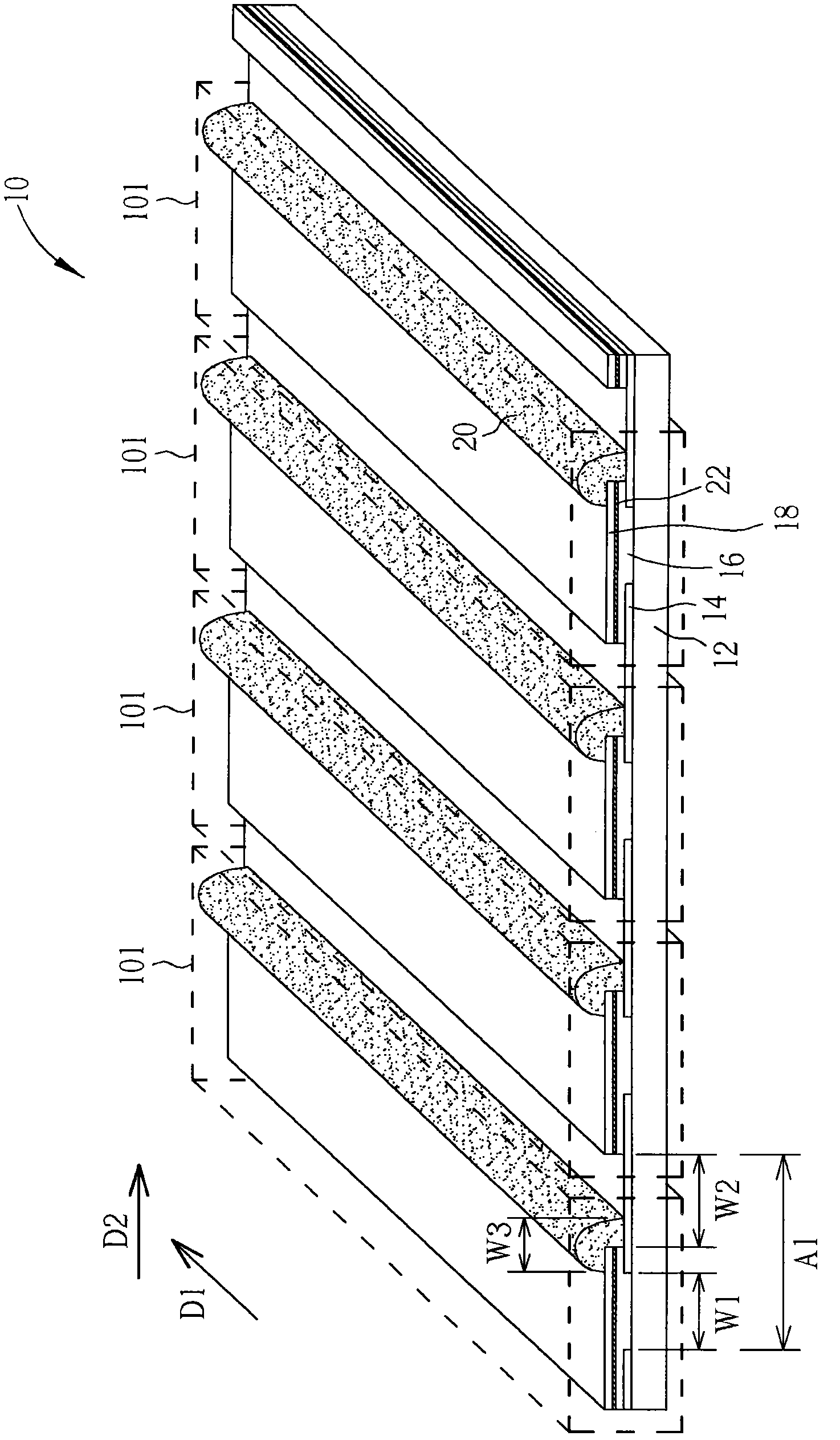

[0036] see figure 1 , figure 1 It is a schematic diagram of the solar cell module 10 according to the first embodiment of the present invention. The solar cell module 10 includes a substrate 12 , a plurality of strip-shaped first electrodes 14 , a plurality of strip-shaped photoelectric conversion layers 16 , a plurality of strip-shaped second electrodes 18 and a plurality of conductive layers 20 . Such as figure 1 As shown, a plurality of strip-shaped first electrodes 14 are respectively formed on the substrate 12 at intervals along the first direction D1, wherein the width W1 of the part of the substrate 12 exposed between two adjacent strip-shaped first electrodes 14 may be about 50 Micron. The strip-shaped photoelectric conversion layer 16 is formed between adjacent strip-shaped first electrodes 14 and on the substrate 12 along the first direction D1, and part of the strip-shaped first electrode is exposed between adjacent strip-shaped photoelectric conversion layers 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com