Automatic solidifying line for photovoltaic modules

A photovoltaic module and assembly line technology, applied in electrical components, semiconductor devices, circuits, etc., can solve problems affecting appearance quality and internal performance, micro-cracks in internal cell parts, affecting product working life, etc., to improve the economic efficiency of enterprises, Solve hidden quality problems and achieve the effect of process improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so that the protection scope of the present invention can be more clearly defined.

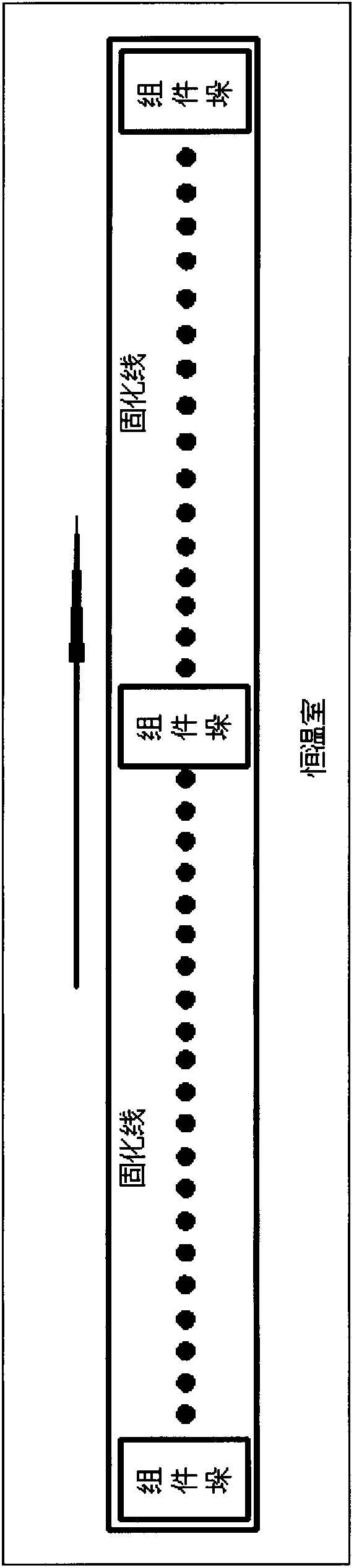

[0023] Such as figure 1 An automatic curing assembly line for photovoltaic modules is shown, which stacks the assembled and to-be-cured colloidal photovoltaic modules together, and then puts them on the curing transmission line in the constant temperature chamber according to the production time sequence; starts the curing transmission line, the curing line The control system will control the curing line to run at a specific speed. This specific speed is guaranteed to be about four hours. The photovoltaic modules placed at one end of the curing line are transported to the other end; the subsequent production of photovoltaic modules is placed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com