rosette ni(oh) 2 /rgo composite electrode material and its preparation method and application

A composite electrode and composite material technology, applied in the field of composite materials, can solve the problems of difficulty in effectively improving material stability and uneven contact, and achieve the possible effects of improving stability, increasing actual specific capacitance, and reducing structural changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

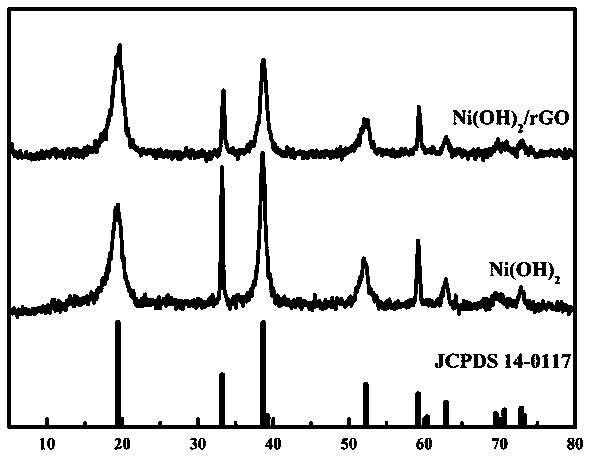

[0029] The present invention relates to rosette Ni(OH) 2 The preparation method of / rGO composite electrode material comprises the following steps:

[0030] Step 1: Rosette Ni(OH) 2 Preparation of / rGO composites:

[0031] Ultrasonic disperse 0.01-0.2g of graphene oxide into 100mL of deionized water to obtain graphene oxide mother liquor; take 30-60mL of graphene oxide mother liquor and heat it in a water bath, add 1-5ml of glycerin, and stir vigorously until it is fully mixed; then, 0.1 -0.6g of nickel salt is poured in, stirred until the nickel salt is completely dissolved to form a dark green solution; then, the resulting solution is added to a hydrothermal kettle for hydrothermal reaction, and the product is centrifugally washed and dried to obtain a rose-like Ni(OH) 2 / rGO composites;

[0032] Step 2: Rosette Ni(OH) 2 Preparation of / rGO composite electrode material:

[0033] Acetylene black, polyvinylidene fluoride and rosette Ni(OH) 2 The / rGO composite material i...

Embodiment 1

[0041] Step 1: Rosette Ni(OH) 2 Preparation of / rGO composites

[0042]Ultrasonic disperse 0.05g of graphene oxide into 100mL of deionized water to obtain a graphene oxide mother liquor; take 40mL of the above mother liquor and heat it in a water bath, add 1ml of glycerin, and stir vigorously until it is fully mixed. Subsequently, 0.3 g of nickel salt was poured into the dispersion, and stirred until all the nickel salt was dissolved to form a dark green solution. Next, add the solution obtained above into an 80mL hydrothermal kettle with a filling ratio of 50%, and keep it warm at 180°C for 5h. After the reaction is completed, the product is centrifugally washed and dried to obtain a rose-shaped Ni(OH) 2 / rGO composites.

[0043] Step 2: Preparation of composite electrode material

[0044] Mix acetylene black, polyvinylidene fluoride (PVDF) and the resulting composite material at a mass ratio of 1:1:8, add N-methylpyrrolidone (NMP) dropwise, and then apply it on a 1cm×2cm ...

Embodiment 2

[0046] Step 1: Rosette Ni(OH) 2 Preparation of / rGO composites

[0047] Ultrasonic disperse 0.05 g of graphene oxide into 100 mL of deionized water to obtain a graphene oxide mother liquor; take 46 mL of the above mother liquor and heat in a water bath, add 2 ml of glycerin, and stir vigorously until it is fully mixed. Subsequently, 0.416 g of nickel acetate was poured into the dispersion, and stirred until the nickel salt was completely dissolved to form a dark green solution. Next, add the solution obtained above into an 80mL hydrothermal kettle with a filling ratio of 60%, and keep it warm at 200°C for 3.5h. After the reaction is completed, the product is centrifugally washed and dried to obtain a rose-shaped Ni(OH) 2 / rGO composites.

[0048] Step 2: Preparation of composite electrode material

[0049] Mix acetylene black, polyvinylidene fluoride (PVDF) and the resulting composite material at a mass ratio of 1:1:8, add N-methylpyrrolidone (NMP) dropwise, and then apply ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com