Insulated piercing wire clip

A technology of insulation puncture and clamp, applied in the direction of needle tip/slotted plate contact, clamping/spring connection, electrical components, etc. used to penetrate insulating wire/cable core wire, which can solve the problem of unreasonable internal structure and use Problems such as short service life and unstable performance, etc., achieve the effect of simple pressure resistance, good sealing, and variable pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

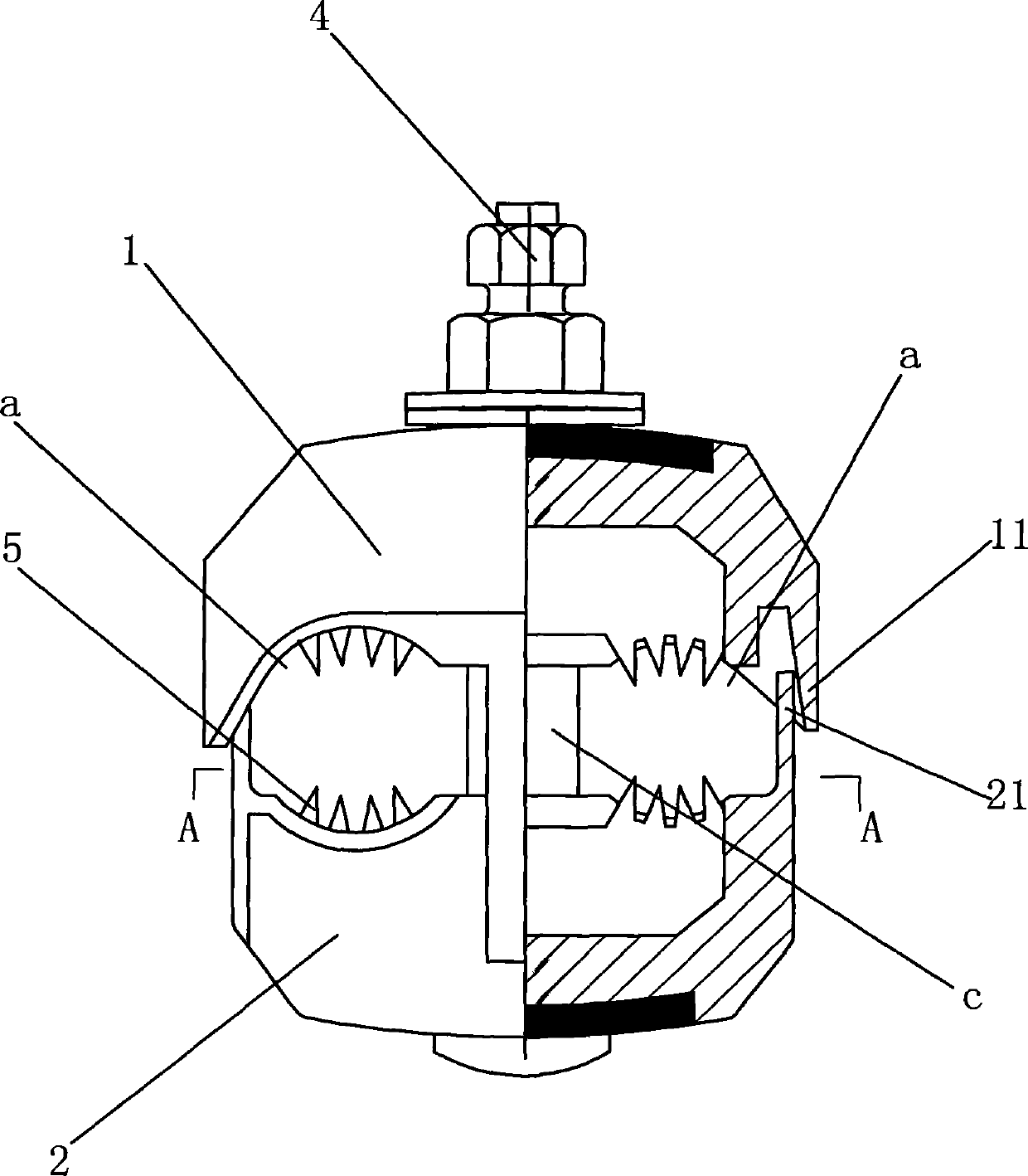

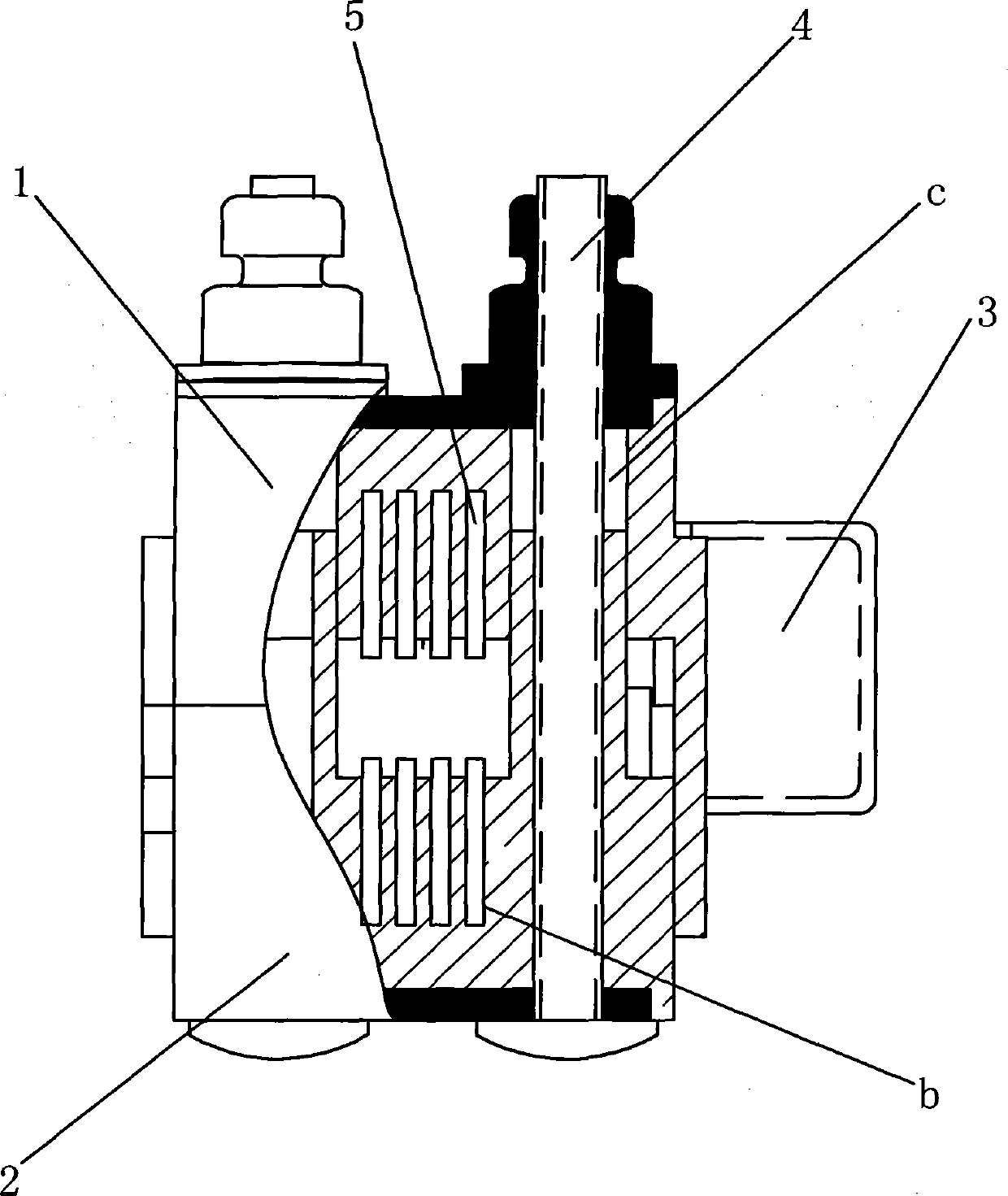

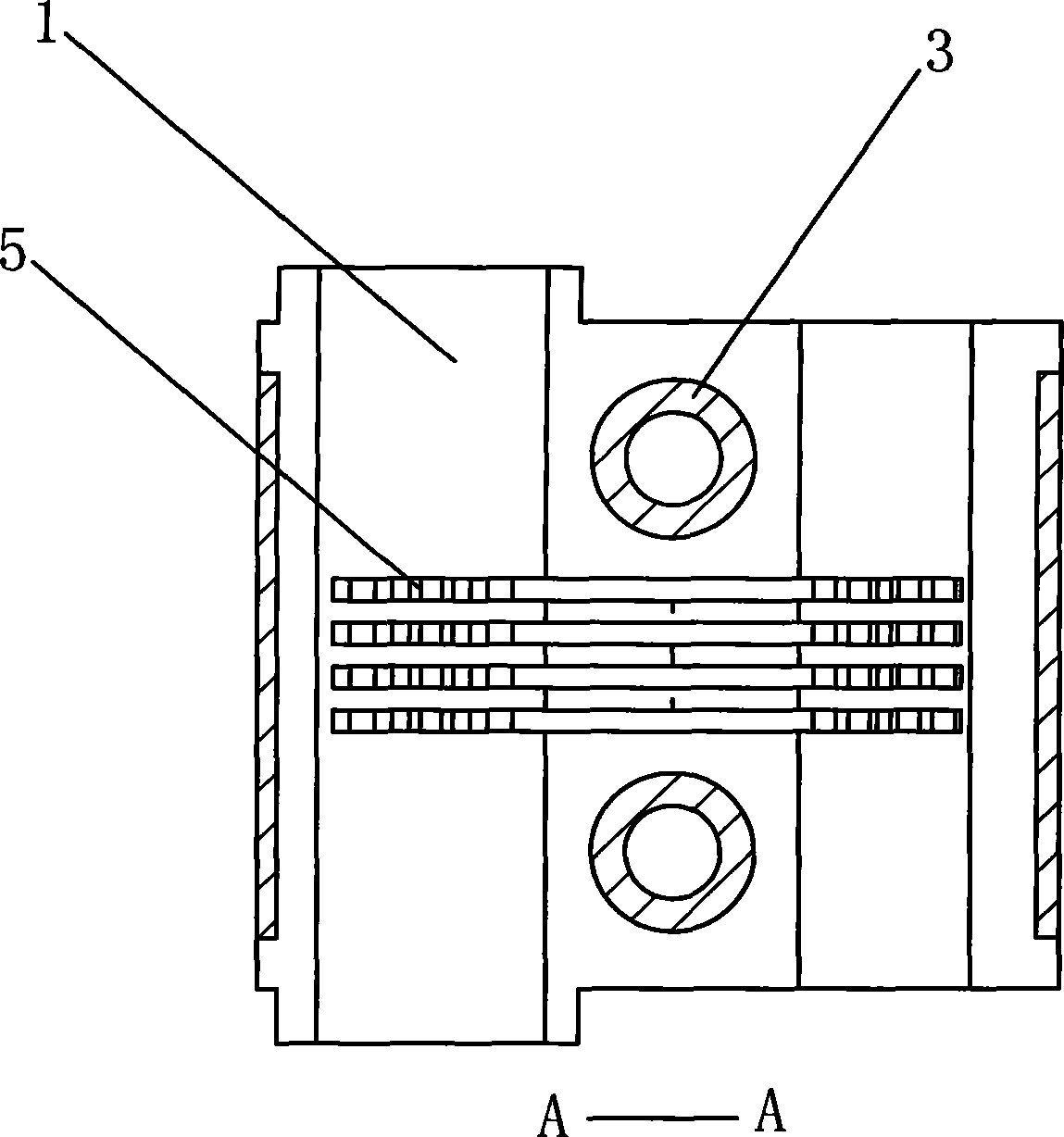

[0017] like Figure 1-3 As shown, the specific embodiment of the present invention is an insulating puncture clamp, including an insulating upper cover 1, an insulating lower seat 2, a plastic case cover 3, two torque bolts 4 and four sets of piercing blades 5, an insulating upper cover 1 and an insulating lower Two semicircular through-holes a are arranged horizontally on the seat 2, and four sets of mounting grooves b are respectively arranged on the insulating upper cover 1 and the insulating lower seat 2 in the longitudinal direction, and eight sets of piercing blades 5 are fixedly arranged on the insulating upper cover 1 respectively. In the eight sets of installation grooves b of the insulating lower seat 2, a bolt mounting platform c is provided in the middle part of the insulating upper cover 1 and the insulating lower seat 2, and the piercing blade 5 is fixedly arranged between the two bolt installing platforms c. The cover 1 and the insulating lower seat 2 are fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com