Contact element component and hermetic seal connector using component

A technology of contacts and electrical connectors, applied in the direction of connection, parts of connecting devices, electrical components, etc., can solve the problem of heavy weight of electrical connectors, meet the requirements of reducing bonding performance, solve heavy weight, and relieve heat resistance The effect of the limitation of properties and bonding with glass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

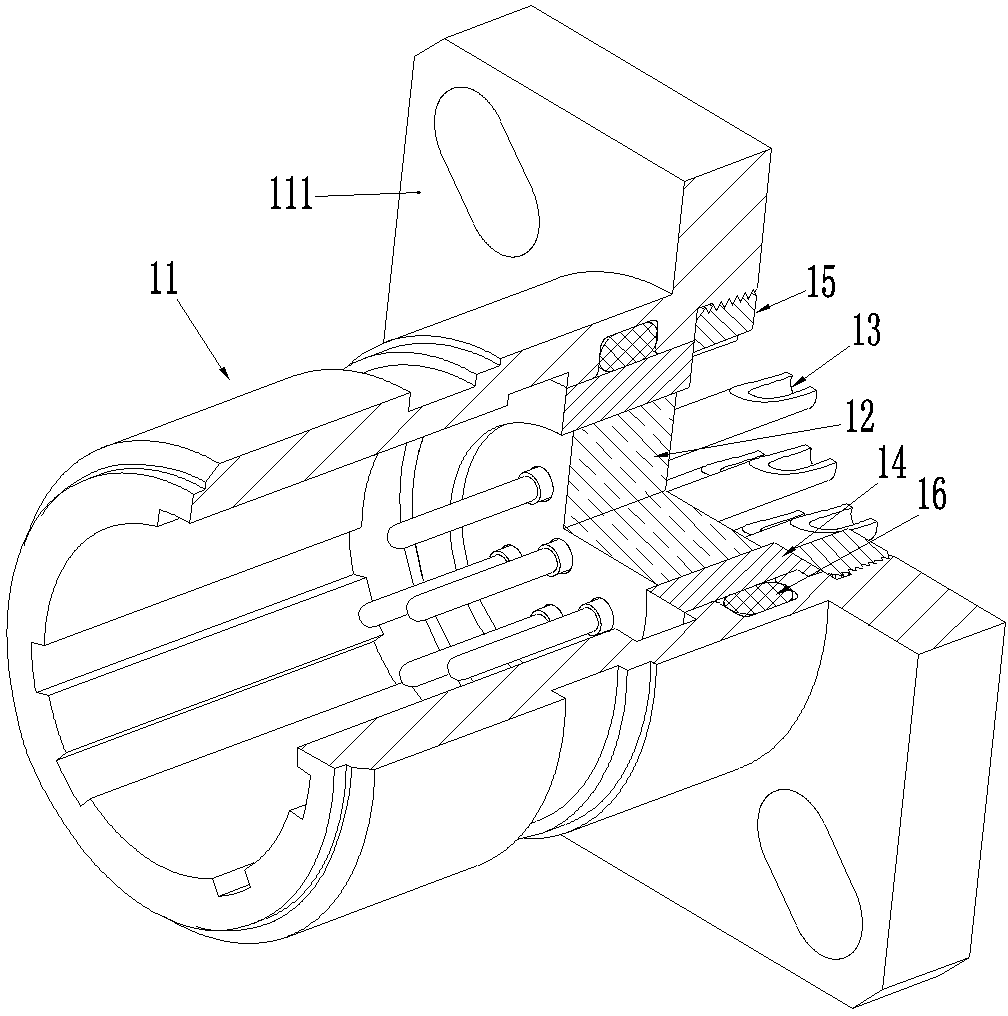

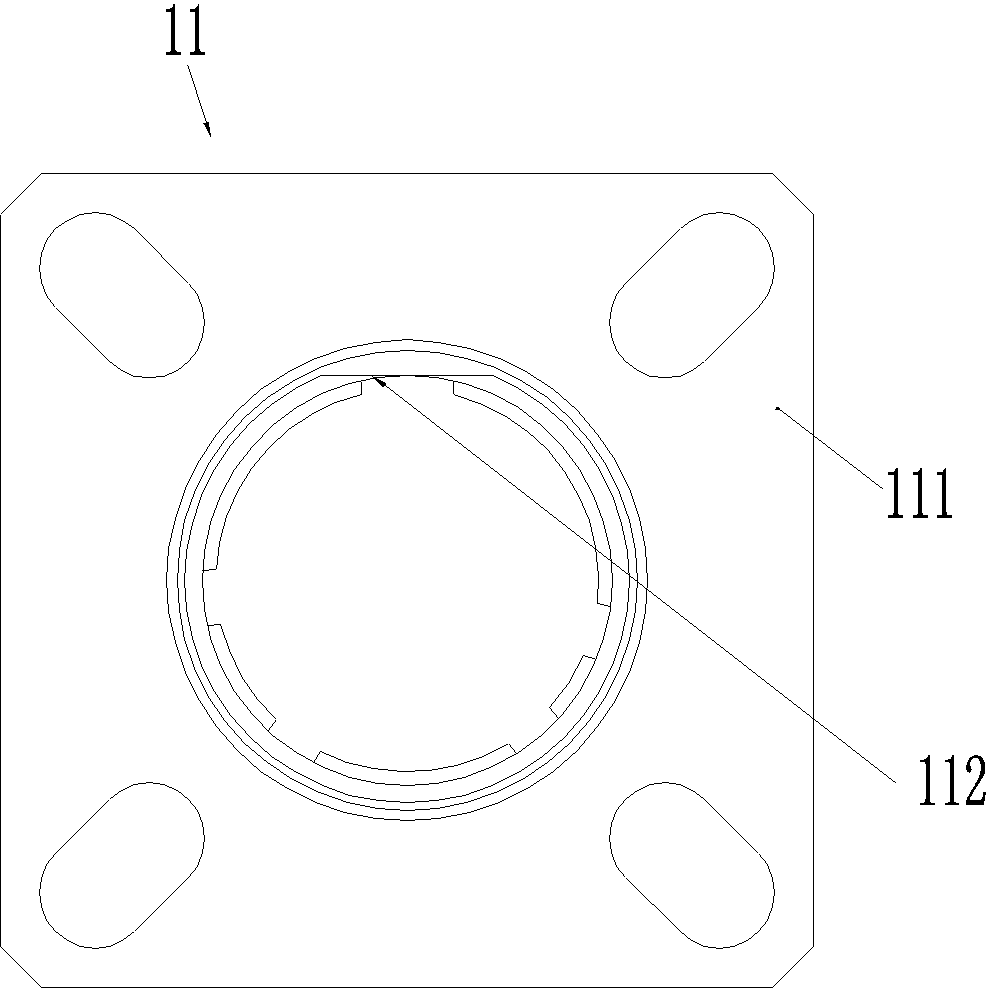

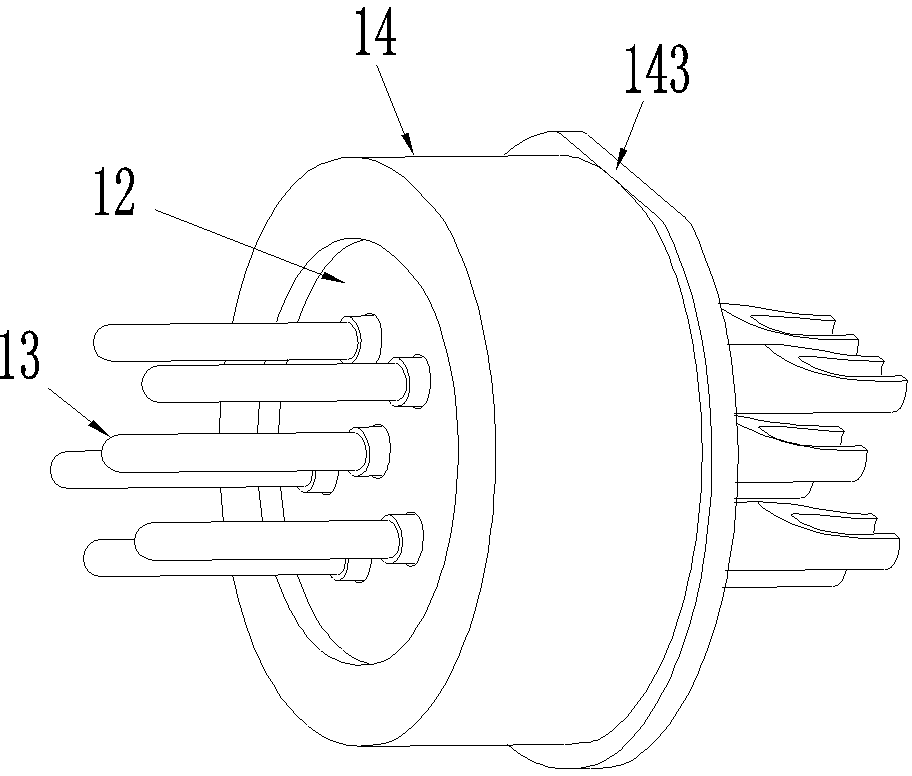

[0024] Embodiment 1 of the electrical connector of the present invention, such as Figure 1-6 As shown, the housing 11 is included. In this embodiment, the main part of the housing 11 is cylindrical and the rear end is provided with a mounting plate 111 for matching with the corresponding mounting panel. In addition, the housing 11 adopts a high-strength, Made of light-weight composite plastic, the housing 11 is equipped with a contact assembly, the contact assembly includes a glass insulator 12, the glass insulator 12 is a glass cake with holes, and the hole of the glass insulator 12 is equipped with a contact 13, the glass insulator The outside of 12 is covered with a metal sheath 14, and the three are sintered and fixed together after assembly. In other words, the metal sheath 14 and the contact piece 13 are sintered and fixed together through the glass insulator 12, forming a seamless connection between the three. With reliable sealing performance, the front end of the met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com