Motor

A technology of insulating sleeve and rotor core, applied in the shape/style/structure of winding insulation, etc., can solve problems such as insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

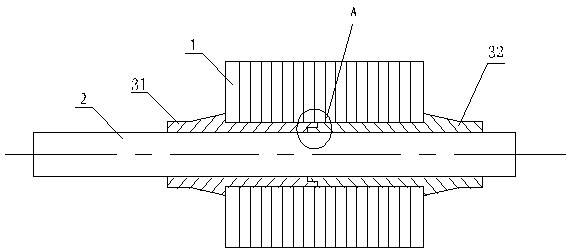

[0012] Such as figure 1 As shown, the motor according to the embodiment of the present invention includes a rotor composed of a shaft 2, a rotor core 1 mounted on it, and two insulating sleeves 31 and 32, and the two insulating sleeves 31 and 32 are sleeved on On the shaft 2, the rotor core 1 is sheathed on two insulating sleeves; one ends of the two insulating sleeves are correspondingly connected.

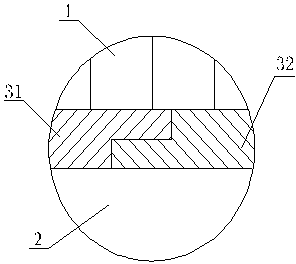

[0013] figure 1 The insulating sleeves 31 and 32 shown in , extend out of the rotor core 1 respectively, that is, the assembly degree of the two insulating sleeves is greater than that of the rotor core, and the protruding part extends radially along the rotor core 1 to form a flange; At the same time, the end faces of the corresponding ends connected by the two insulating sleeves are set to be gradient matching, such as figure 2 Partial enlargement is shown.

[0014] In order to further enhance the connection strength of the two insulating sleeves, a conventional snap-fit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com