PWM (pulse width modulation) based servo system

A pulse width modulation, servo system technology, applied in control systems, AC motor control, electrical components, etc., can solve the problems of noise sensitivity, time drift of analog circuits, etc., to achieve small pulsation, simple circuit, strong noise immunity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

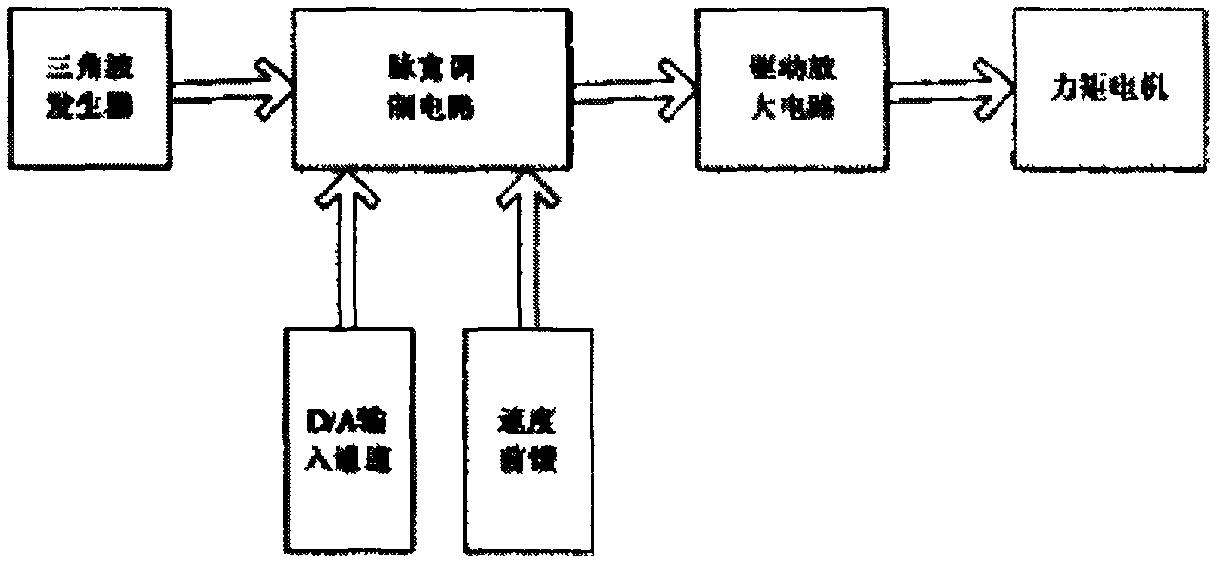

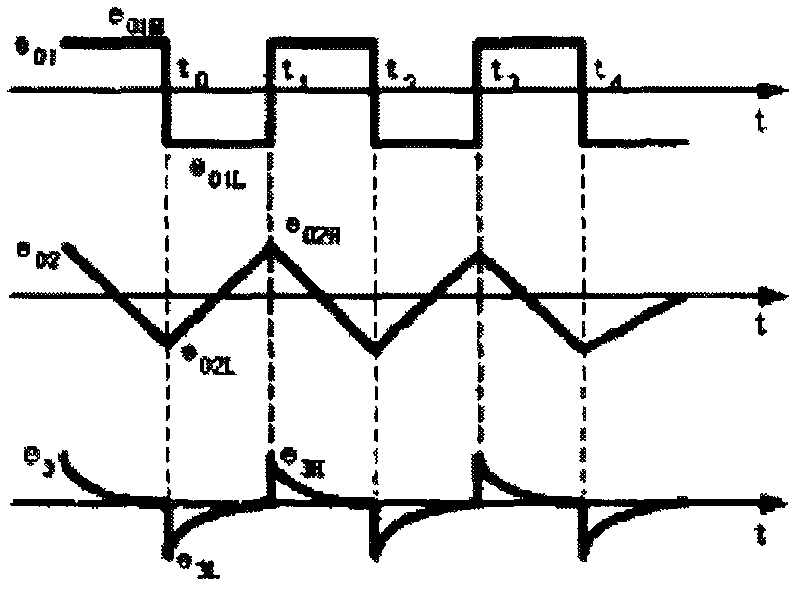

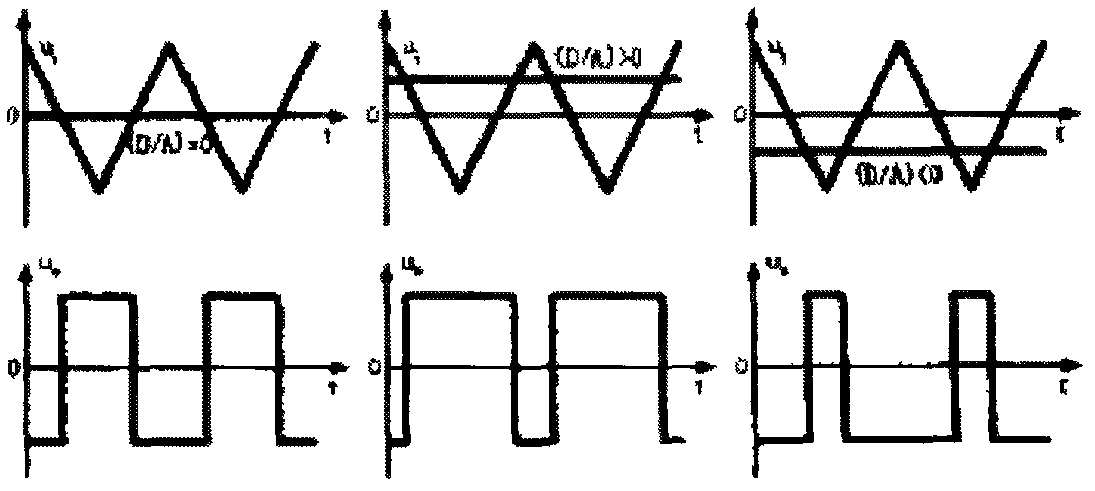

[0009] Below in conjunction with accompanying drawing, the technical scheme realization method of invention is described: figure 1 Among them, a servo system based on PWM pulse width modulation, including triangular wave generator, pulse width modulation circuit, D / A input channel, speed feedforward, drive amplifier circuit and actuator; triangular wave generator, D / A input channel, speed The output end of the feedforward is connected with the input end of the pulse width modulation circuit, the output end of the pulse width modulation circuit is connected with the input end of the drive amplifier circuit, and the output end of the drive amplifier circuit is connected with the input end of the torque motor. Specifically, it includes triangular wave generator, pulse width modulation circuit, D / A input channel, speed feedforward, drive amplifier circuit and actuator; triangular wave generator, D / A input channel, output terminal of speed feedforward and pulse width modulation The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com