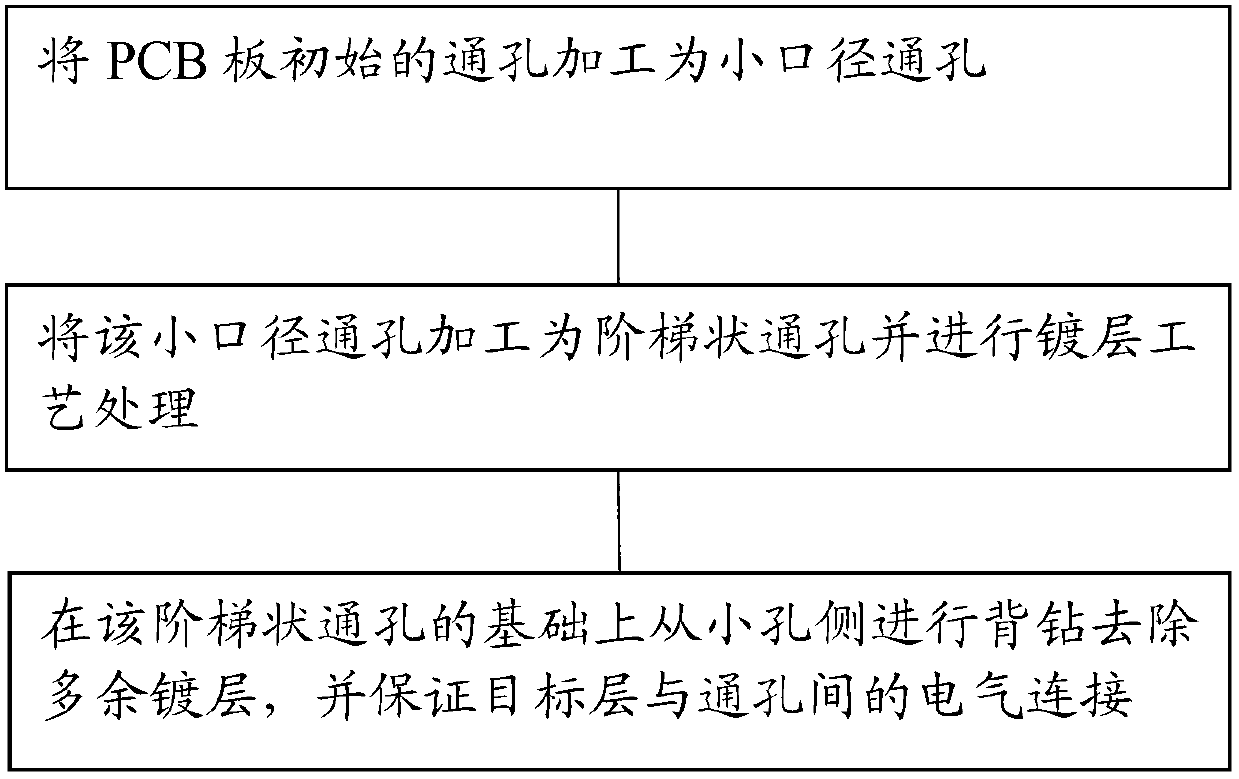

PCB (printed circuit board) back drilling method and PCB through hole structure

A PCB board and back-drilling technology, which is applied in the direction of electrical connection formation of printed components, electrical connection of printed components, printed circuit components, etc., can solve the problems that the back-drilling process cannot be carried out, and achieve the effect of low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

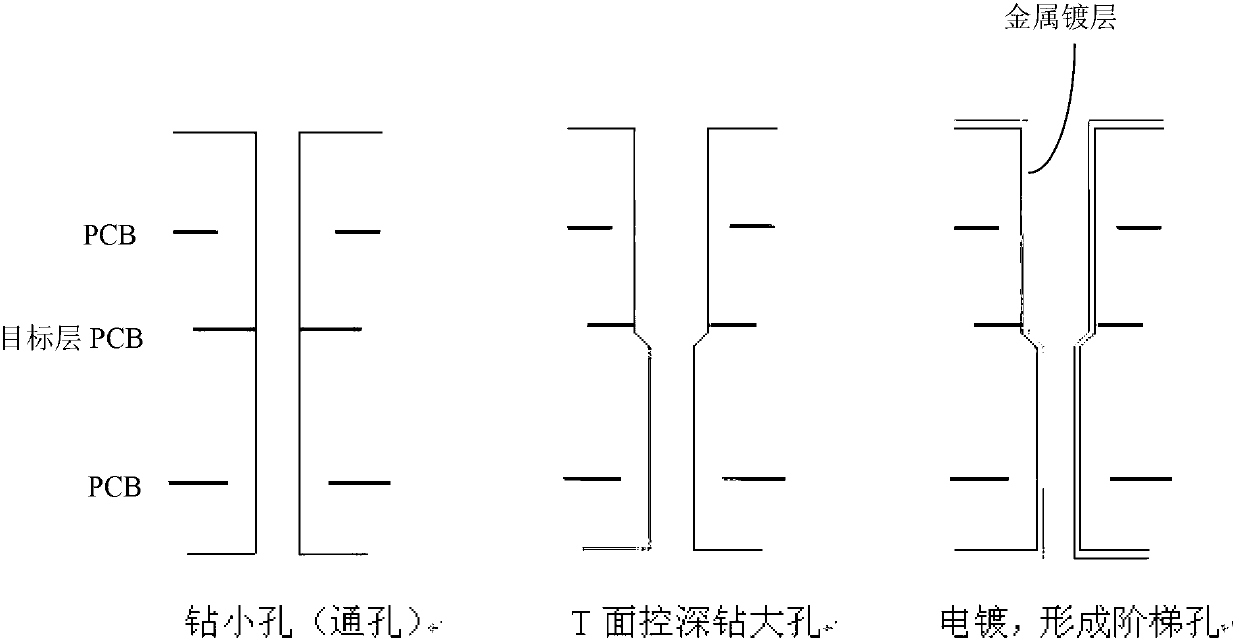

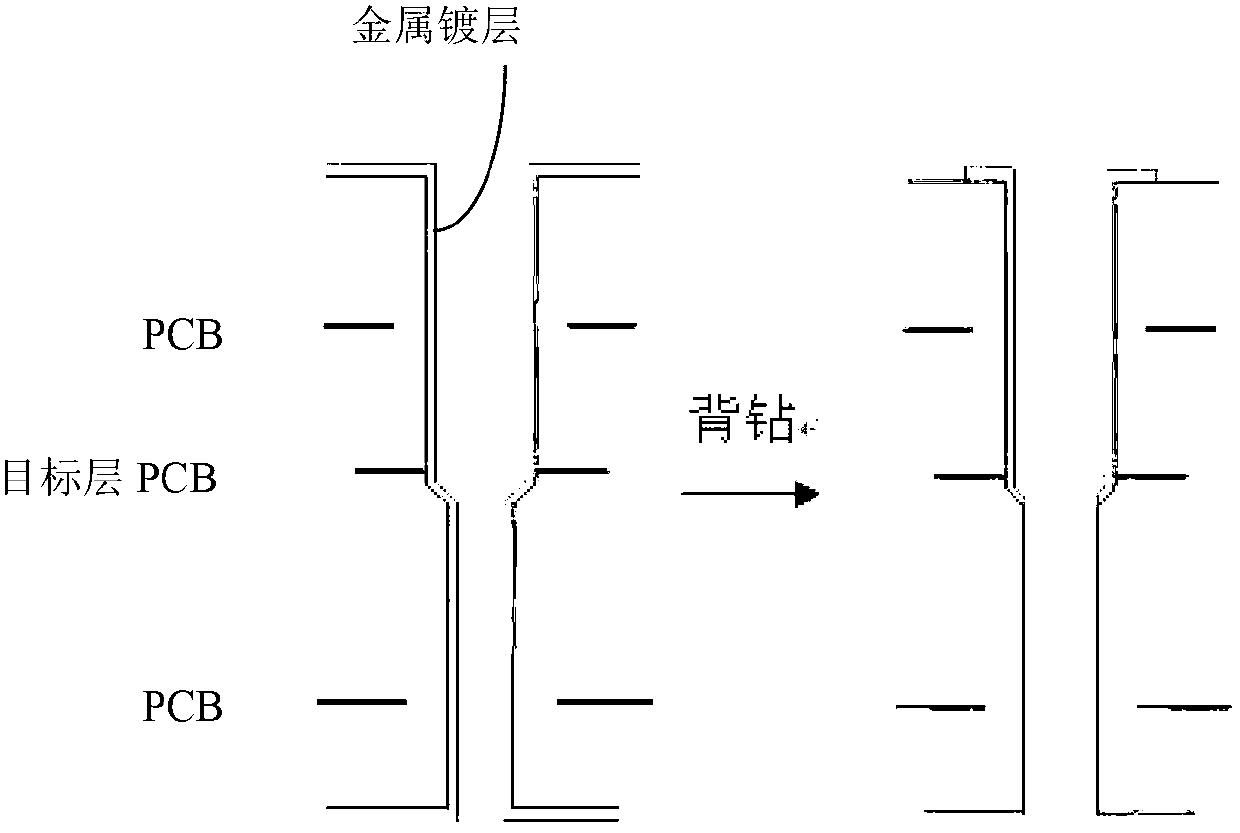

[0024] In order to achieve the purpose of the present invention, the core idea adopted by the present invention is: for the situation where the distance between the PCB trace or the plane and the through hole is insufficient, first process the initial through hole of the PCB board into a small-diameter through-hole, and then the small-diameter through-hole It is processed into a stepped through hole and processed by metal coating process. Finally, on the basis of the stepped through hole, back-drill from the small hole side to remove the excess metal coating, and ensure the coating electrical between the printed circuit of the target layer PCB board and the through hole. connect. Through the present invention, since the back-drilling process is carried out from the small hole side of the stepped hole, the diameter of the back-drilling hole becomes smaller compared with the conventional back-drilling process, and the distance from the back-drilling hole to the PCB trace or PCB p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap