Preparation method for magnetic polymer composite microsphere

A composite microsphere and polymer technology, applied in chemical instruments and methods, alkali metal compounds, alkali metal oxides/hydroxides, etc., can solve the problems of time-consuming and laborious operation, difficult solid-liquid separation of adsorbents, etc. Conversion into production, easy solid-liquid separation, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

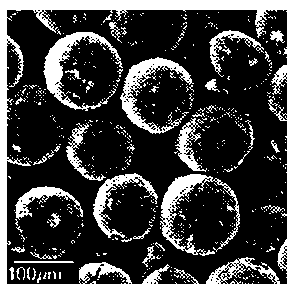

Embodiment 1

[0025] At room temperature, in a 250 mL three-neck flask equipped with a magnetic stirrer and a dropping funnel, add 2.7 g of FeCl 3 ·6H 2 O and 2.8 g FeSO 4 ·7H 2 O (molar ratio 1:1) was dissolved in 50mL water, and N 2 Protect, heat the water bath to a certain temperature (about 50°C), under the condition of vigorous stirring, add 50mL of 1.5mol / L NaOH solution dropwise to the three-necked flask at a uniform speed, and adjust the pH value to greater than 9. After the dropwise addition, stir rapidly for 30 minutes, raise the temperature to 75°C, heat-preserve and mature for 30 minutes, separate the solid and liquid, use 1:1 ethanol / water solution at 25°C to sonicate for 1 hour, wash, and dry under vacuum at 100°C; the prepared Fe 3 o 4 After adding to 2% sodium alginate gel and mixing evenly, slowly drop the magnetic gel to 2% CaCl with a syringe 2 After aging in the solution (100 mL) for 24 h, the Cl on the surface of the gel balls was washed with deionized water. - , ...

Embodiment 2

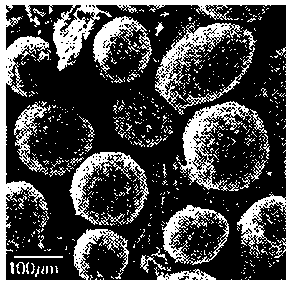

[0028] At room temperature, in a 250 mL three-neck flask equipped with a magnetic stirrer and a dropping funnel, add 2.7 g of FeCl 3 ·6H 2 O and 5.6 g FeSO 4 ·7H 2 O (molar ratio 1:2) was dissolved in 50mL water, and N 2 Protect, heat the water bath to a certain temperature (about 50°C), under the condition of vigorous stirring, add 50mL of 1.5mol / L NaOH solution dropwise to the three-necked flask at a uniform speed, and adjust the pH value to greater than 9. After the dropwise addition, stir rapidly for 30 minutes, raise the temperature to 75°C, heat-preserve and mature for 30 minutes, separate the solid and liquid, use 1:1 ethanol / water solution at 25°C to sonicate for 1 hour, wash, and dry under vacuum at 100°C; the prepared Fe 3 o 4 After adding to 4% sodium alginate gel and mixing evenly, slowly drop the magnetic gel to 4% CaCl with a syringe 2 After aging in the solution (100 mL) for 24 h, the Cl on the surface of the gel balls was washed with deionized water. - , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com