Centrifugal machine special for starch

A centrifuge and starch technology, which is applied in the field of centrifuges, can solve the problems of yellowish starch, difficult separation, short settling time, etc., and achieve the effect of easy cleaning, high purity and white color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below through specific examples.

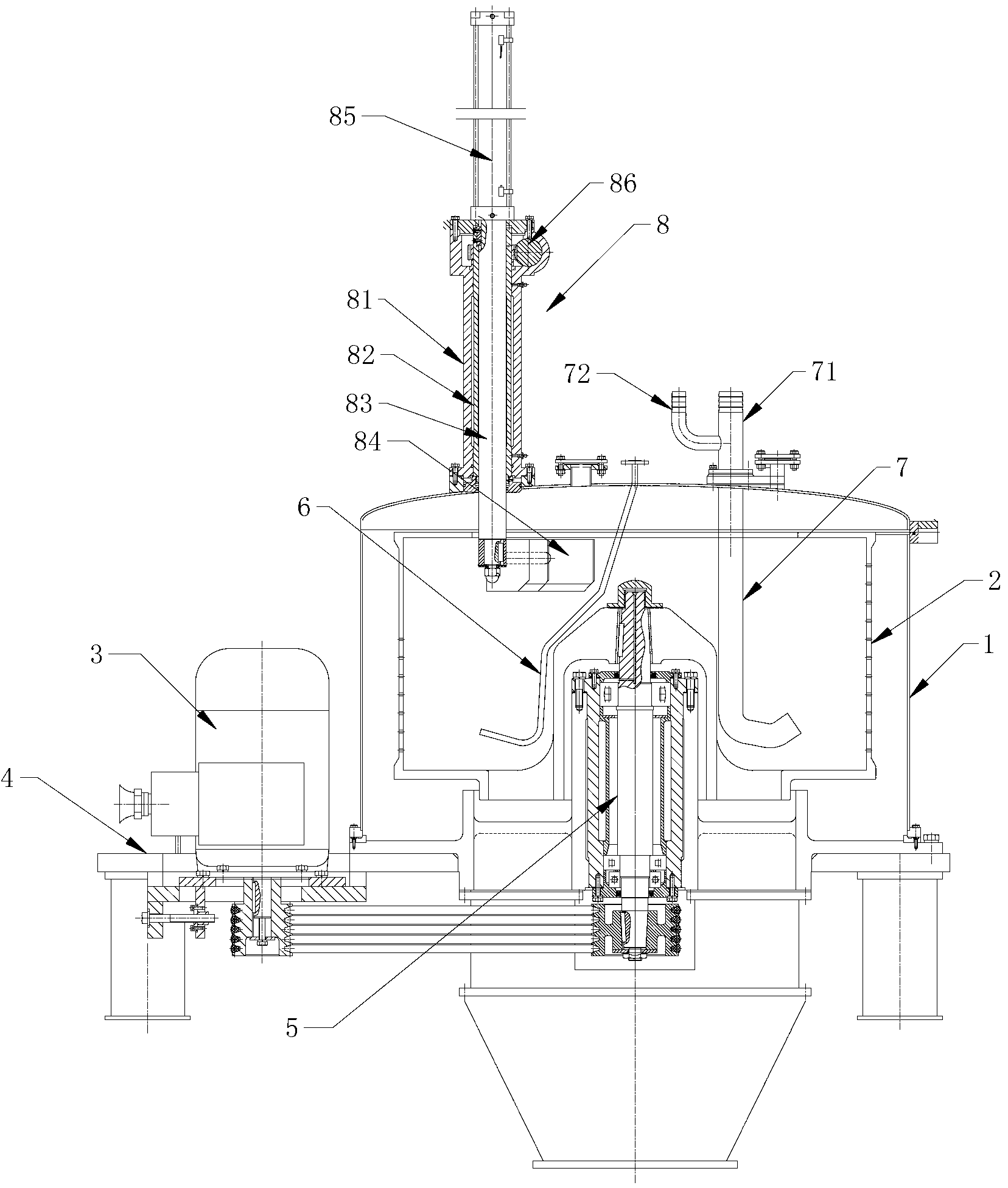

[0021] like figure 1 As shown, a special centrifuge for starch includes a base 4, a housing 1 fixed on the base 4, a main shaft assembly 5 installed on the base 4, a drum 2 arranged on the main shaft assembly 5, and a drum 2 Located in the shell 1, the lower part of the drum 2 is provided with a discharge port, and a drain channel is formed between the outer wall of the drum 2 and the inner side of the shell 1. The main shaft assembly 5 is driven by the motor assembly 3, and the shell 1 is installed There is a scraper 84 assembly 8 for scraping.

[0022] Among them, the frame 4 is different from the three-legged frame 4 currently used. The frame 4 adopts a flat frame 4, and several shells 1 can be fixed on the entire frame 4 at intervals. Each centrifuge shares a machine frame 4. Seat 4, and the driving shaft 83 in the scraper 84 assembly 8 of the centrifuge is controlled by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com