Automatic painting device for inner wall of welded pipe

An automatic paint spraying technology for the inner wall of welded pipes, applied in the direction of spraying devices, etc., can solve the problems of uneven coating of paint cans on the inner wall of welded pipes, waste of labor and materials, and affect the quality of welded pipes, so as to save manpower and material resources, facilitate installation, and reduce labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

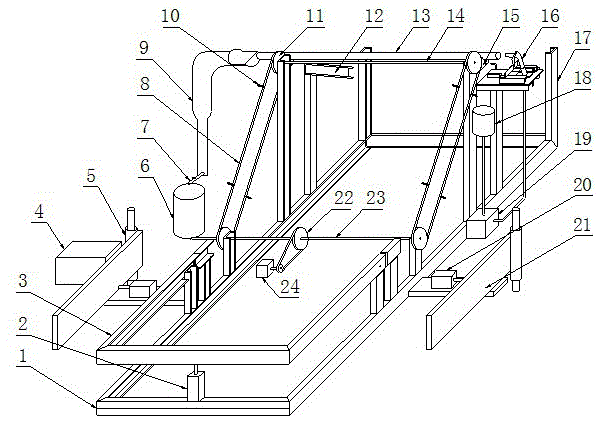

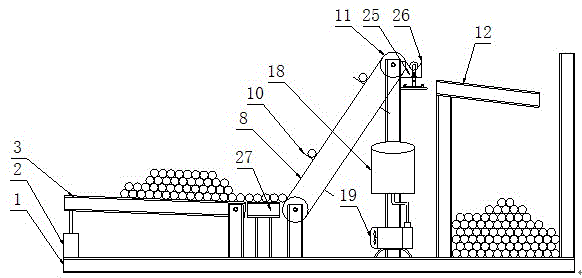

[0019] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

[0020] see figure 1 , figure 2 and image 3 , the embodiment of the present invention provides an automatic painting device for the inner wall of welded pipes. One end of the frame 1 is provided with a welded pipe stacking rack 3 for placing unpainted welded pipes. The automatic conveying device that is transported to the spraying position, one side of the spraying position of the frame 1 is provided with an automatic spraying device.

[0021] Wherein, the automatic spraying device comprises the paint sprayer 16 of the paint sprayer 19 that is movably arranged on the frame 1, and is positioned at the same side frame 1 of the paint sprayer 16 to be provided with two V-shaped welded pipe support frames 15; the paint sprayer 16 and a cylinder A 29 connection, the bottom of the welded pipe support frame 15 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com