Method for calculating thin-wall profile micropore processing

A calculation method and hole processing technology, applied in the field of mechanical processing, can solve problems such as low processing efficiency, positioning troubles, and parts performance requirements cannot be guaranteed, and achieve the effects of simplifying mold structure, reducing labor intensity, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

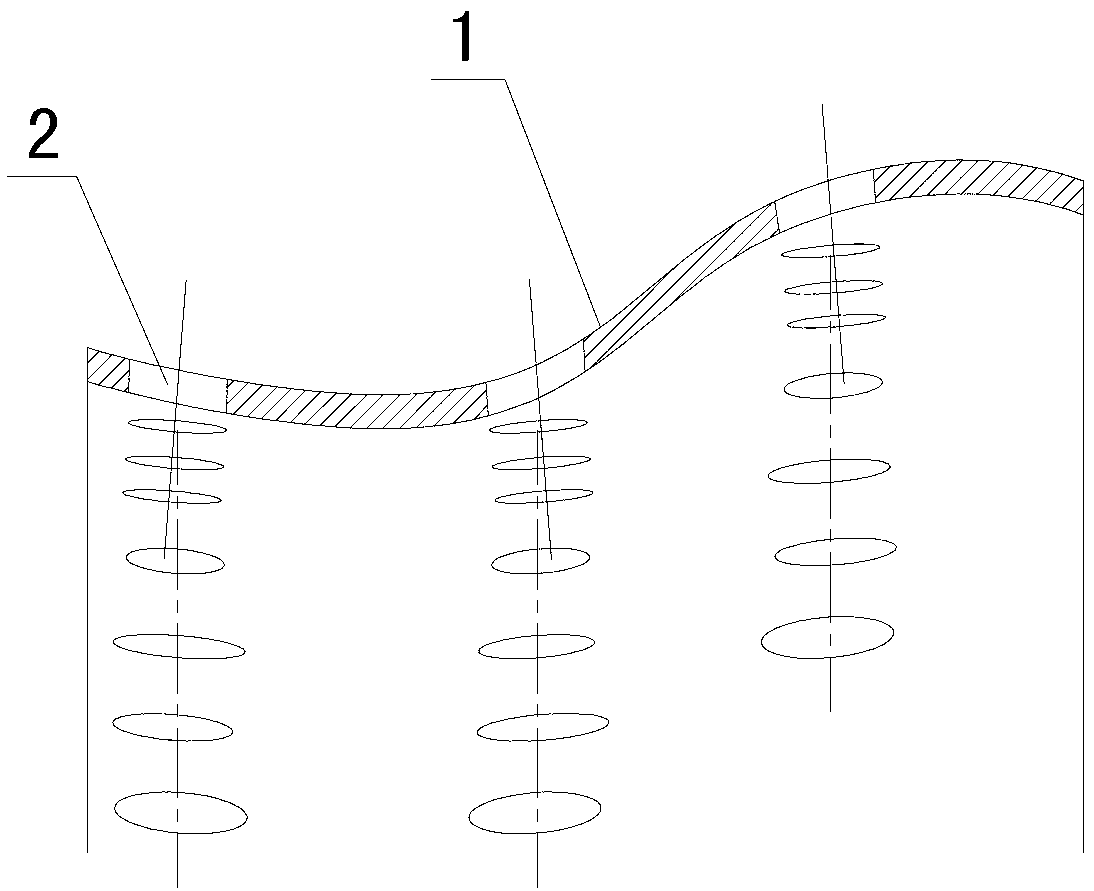

[0016] A calculation method for small hole machining on thin-walled profiles, based on figure 1 Take the part shown as an example, to process multiple small holes 2 on the surface of the thin-walled part 1, and establish the relationship between the size of the small holes and the punch and die, it includes the following steps:

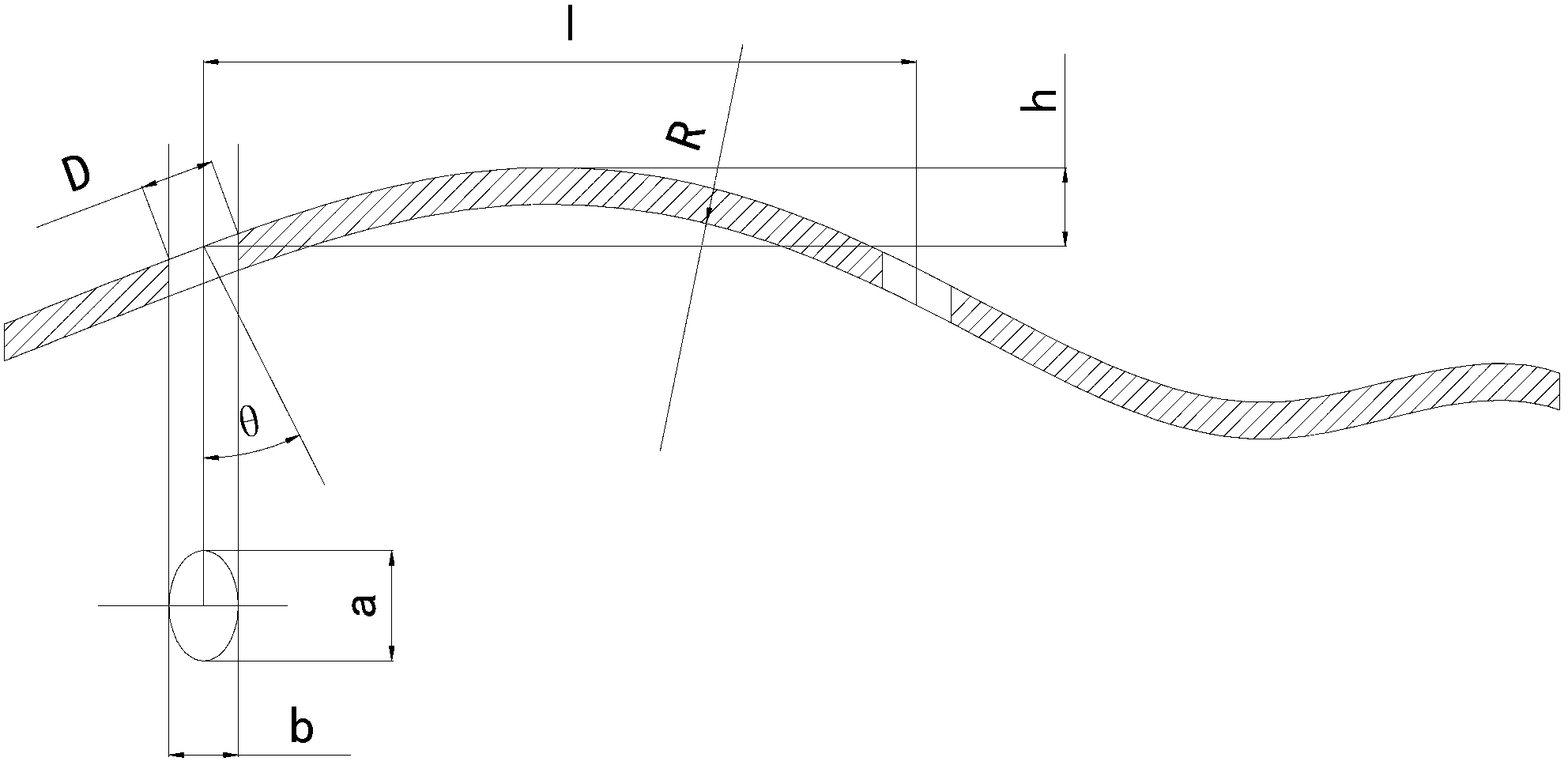

[0017] (1), such as figure 2 , to establish the part surface equation according to the part surface characteristics;

[0018] Select a single complete peak, the center of the arc as the coordinate origin, select one of the circles, and its standard equation is: X 2 +Y 2 -(R+δ) 2 =0.

[0019] Among them: R-surface radius, δ-material thickness.

[0020] (2) Deriving the surface equation to obtain the derivative equation;

[0021] The derivative equation i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com