Rotary inner clamping device

An internal clamping and fixture technology, applied in positioning device, clamping, supporting and other directions, can solve the problems of difficult operation, complex device, complex structure, etc., and achieve the effects of low processing and manufacturing cost, simple structure and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and embodiment the technical solution of the present invention is further described:

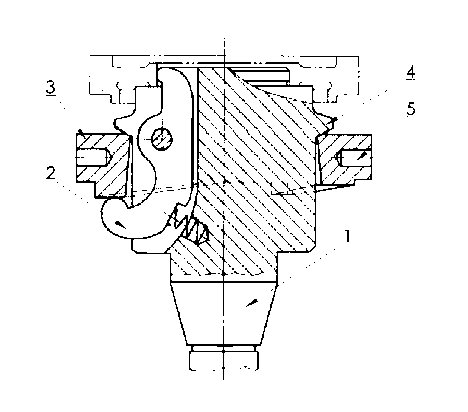

[0013] Such as figure 1 As shown, the present invention provides a rotary internal clamping device, which includes a cylindrical clamp body 1, which is hinged with a circle of evenly distributed claws 2 around the clamp body 1, and the claws 2 rotate radially around the clamp body 1. The driven end is used to clamp the inner hole of the workpiece, and its driving end is against the lower edge of the cam ring 3 sleeved on the fixture main body 1, and the upper edge of the cam ring 3 slides horizontally with a protruding ring 4 provided on the fixture main body 1 Cooperate, the lower edge of the cam ring 3 is provided with a cam against the driving end of the claw 2, the outer edge of the cam ring 3 is provided with a hole 5 for inserting the handle, the claw 2 is provided with three, and the holes 5 for inserting the handle are evenly prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com