High-speed parallel-connection robot pickup device with vision

A pick-up device and robot technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., to achieve good rigidity, high precision and stability, and compact overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The high-speed parallel robot picking device equipped with vision proposed by the present invention will be described in detail below in conjunction with the technical scheme and accompanying drawings:

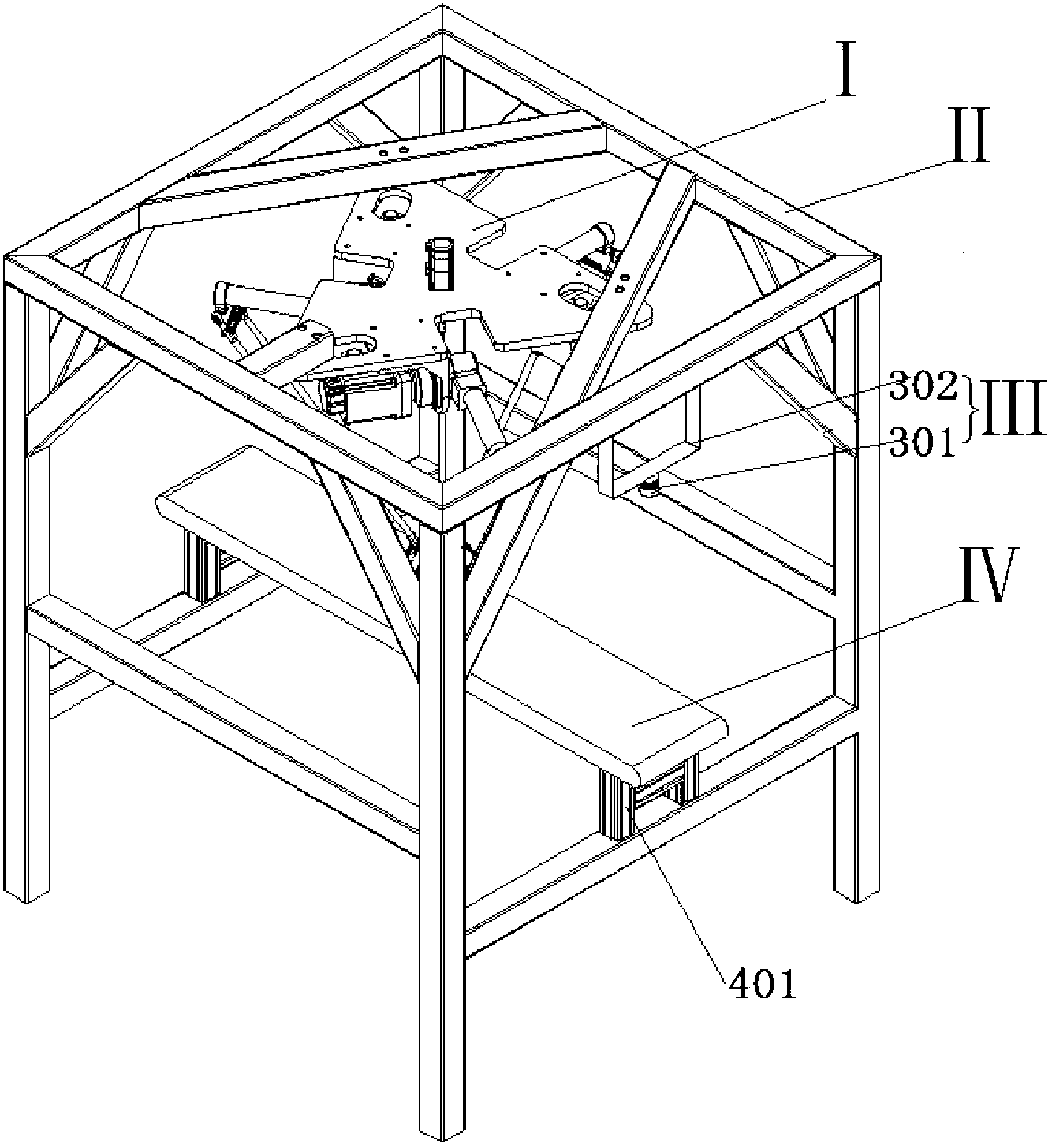

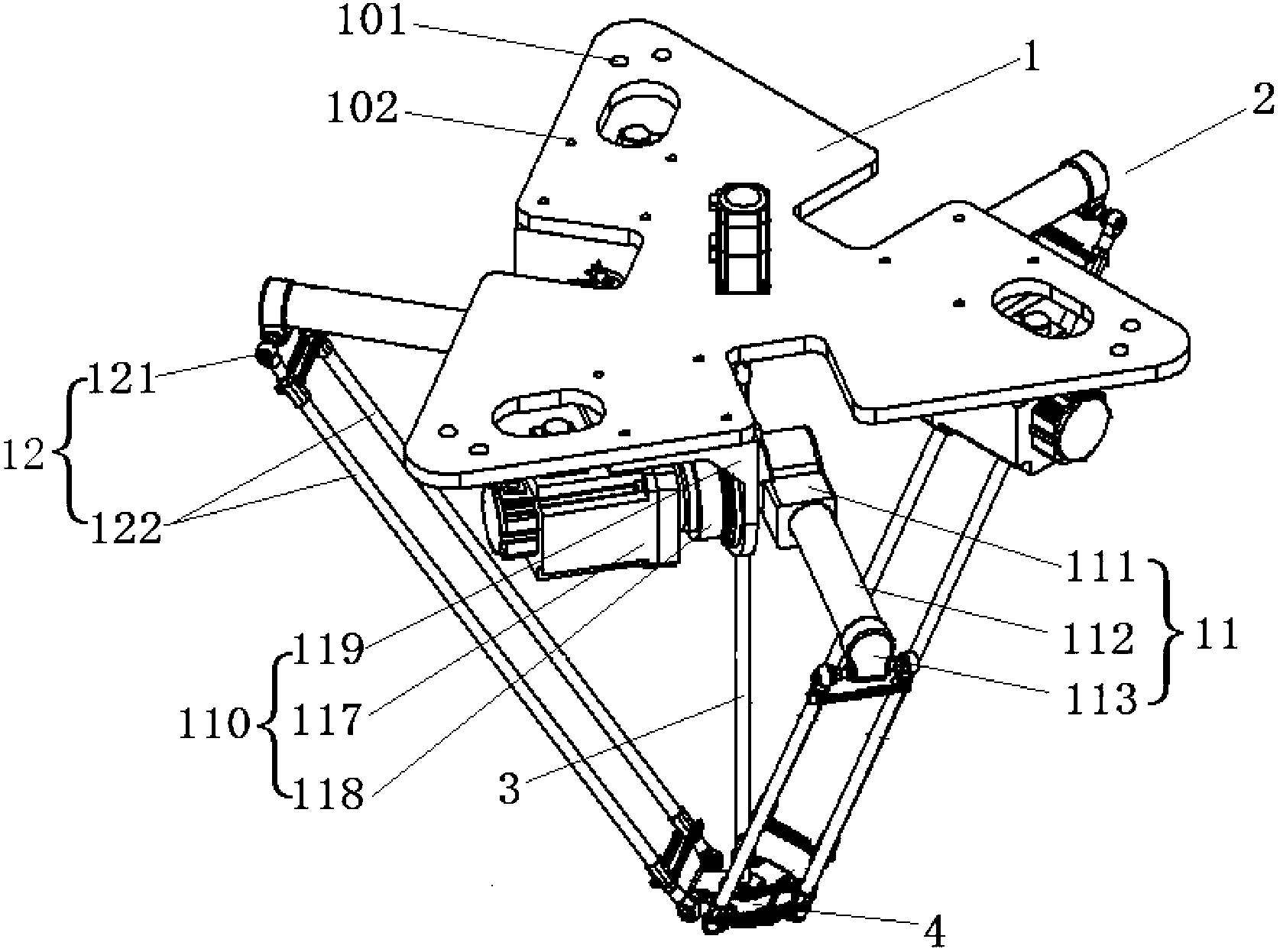

[0025] The vision-equipped high-speed parallel robot picking device proposed by the present invention includes a robot body structure I, a mounting frame II, a vision system III and a transmission system IV. The robot body structure I includes a fixed platform 1, three sets of mechanical arms 2, a rotating shaft 3 and a moving platform 4.

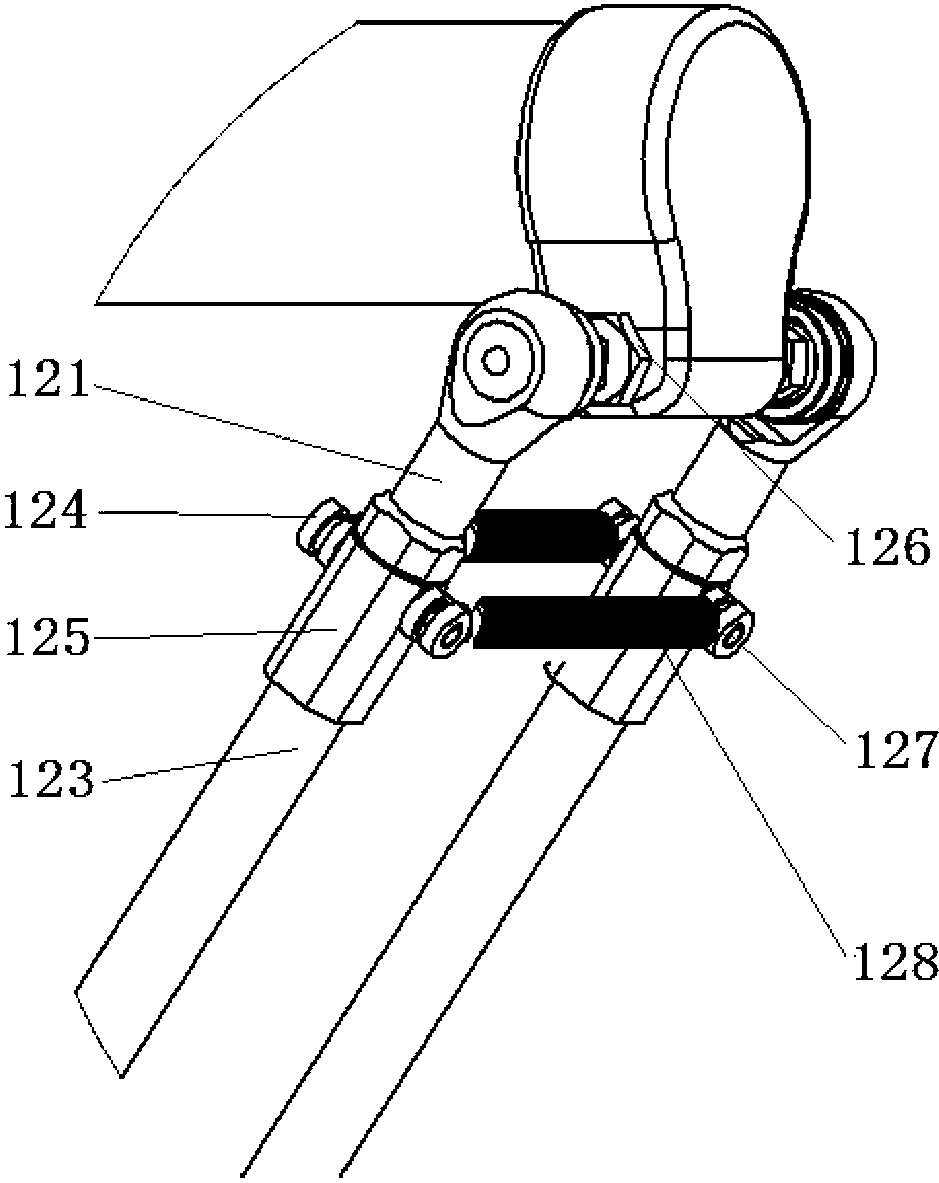

[0026] The fixed platform 1 is triangular in shape, and two mounting holes 101 are provided on each apex of the triangle, and the fixed platform 1 is fixedly connected with the mounting frame II through these mounting holes. An installation opening is provided in the middle of each side of the triangular row, and a threaded hole 102 is provided on one side of the installation opening for the installation of each group of mechanical a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com