Stripper for die for pouring epoxy resin part of GIS (Geographic Information System) basin-type insulator and control device of same

A technology of epoxy resin and pot-type insulation, applied in the field of automatic demoulding machines, can solve the problems of unfavorable mold drawing and mold clamping rigid impact, low degree of automation of the whole machine, unfavorable operation of molds, etc., to achieve easy, convenient and thorough air source Cleaning, high compression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

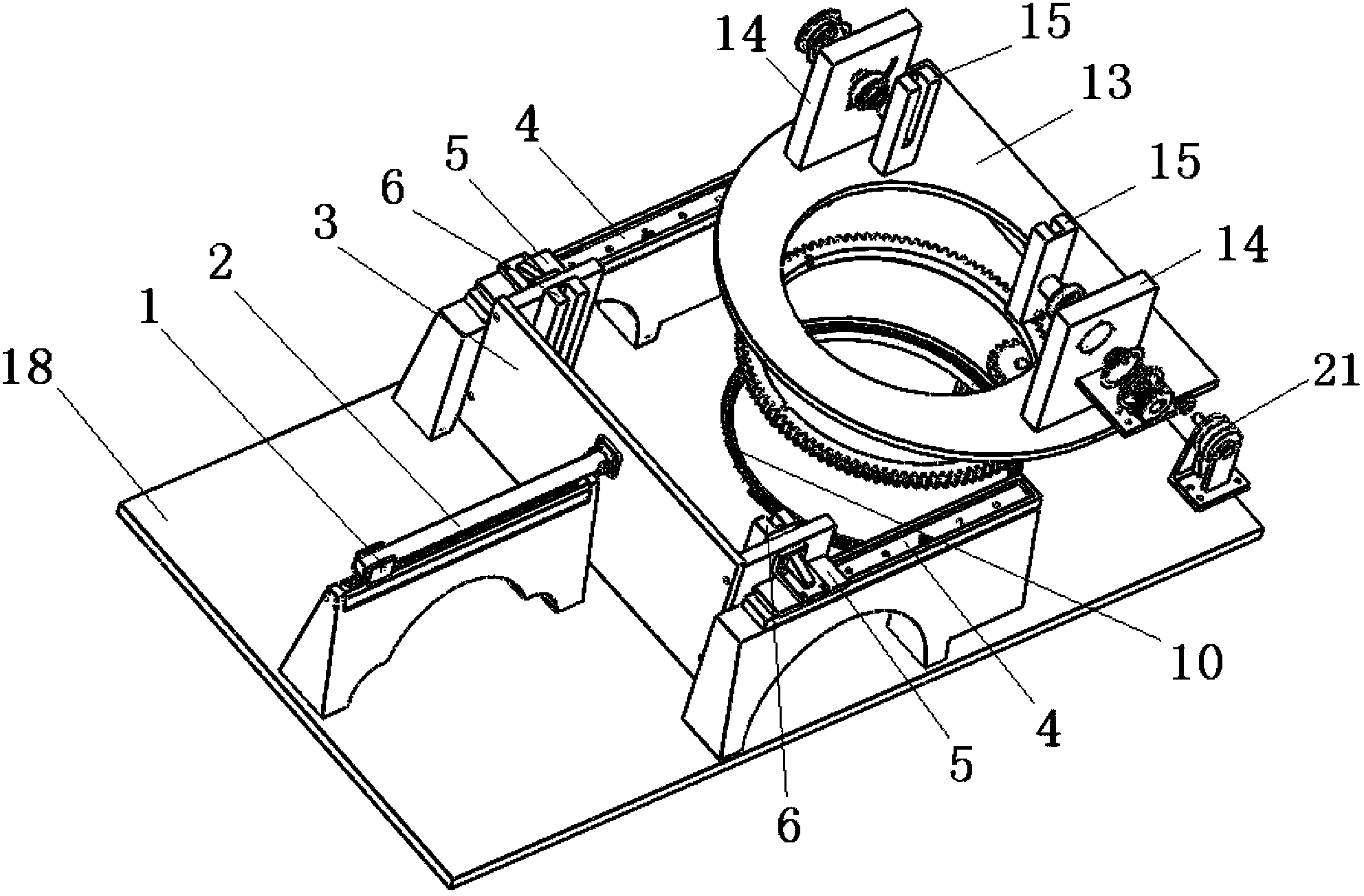

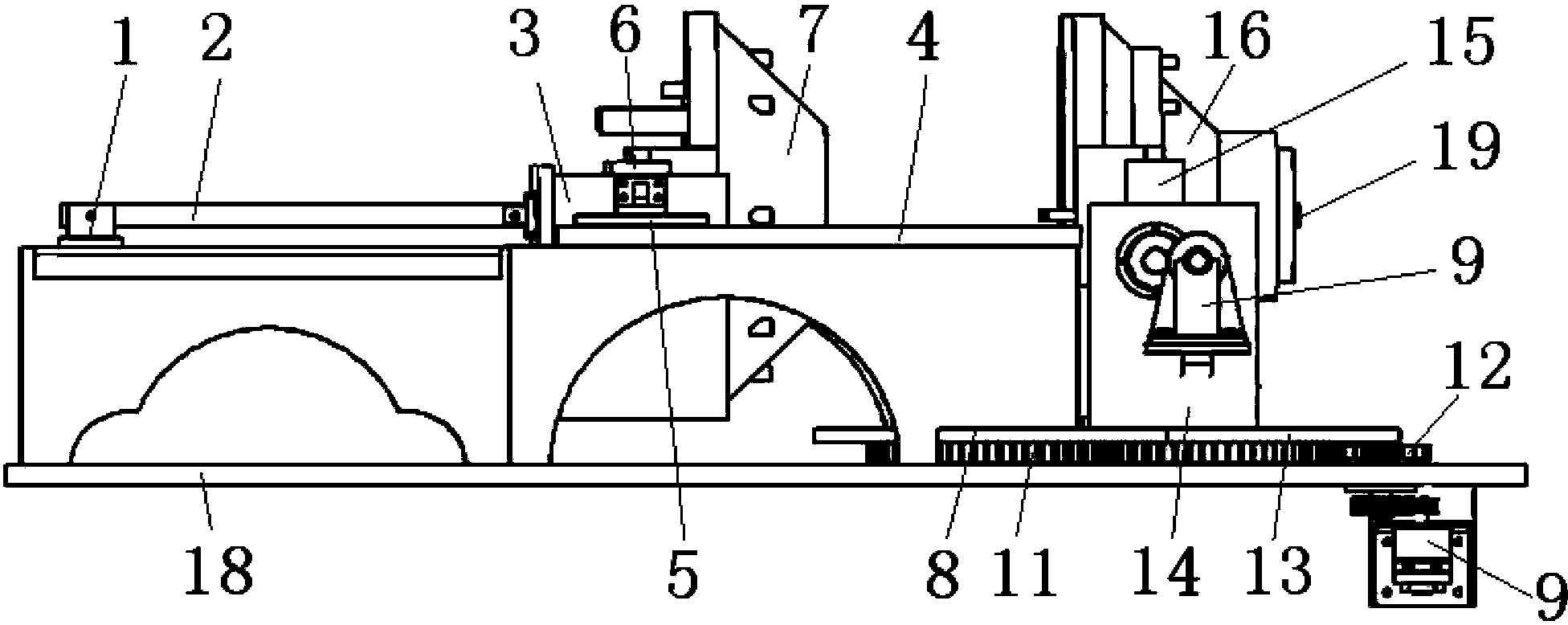

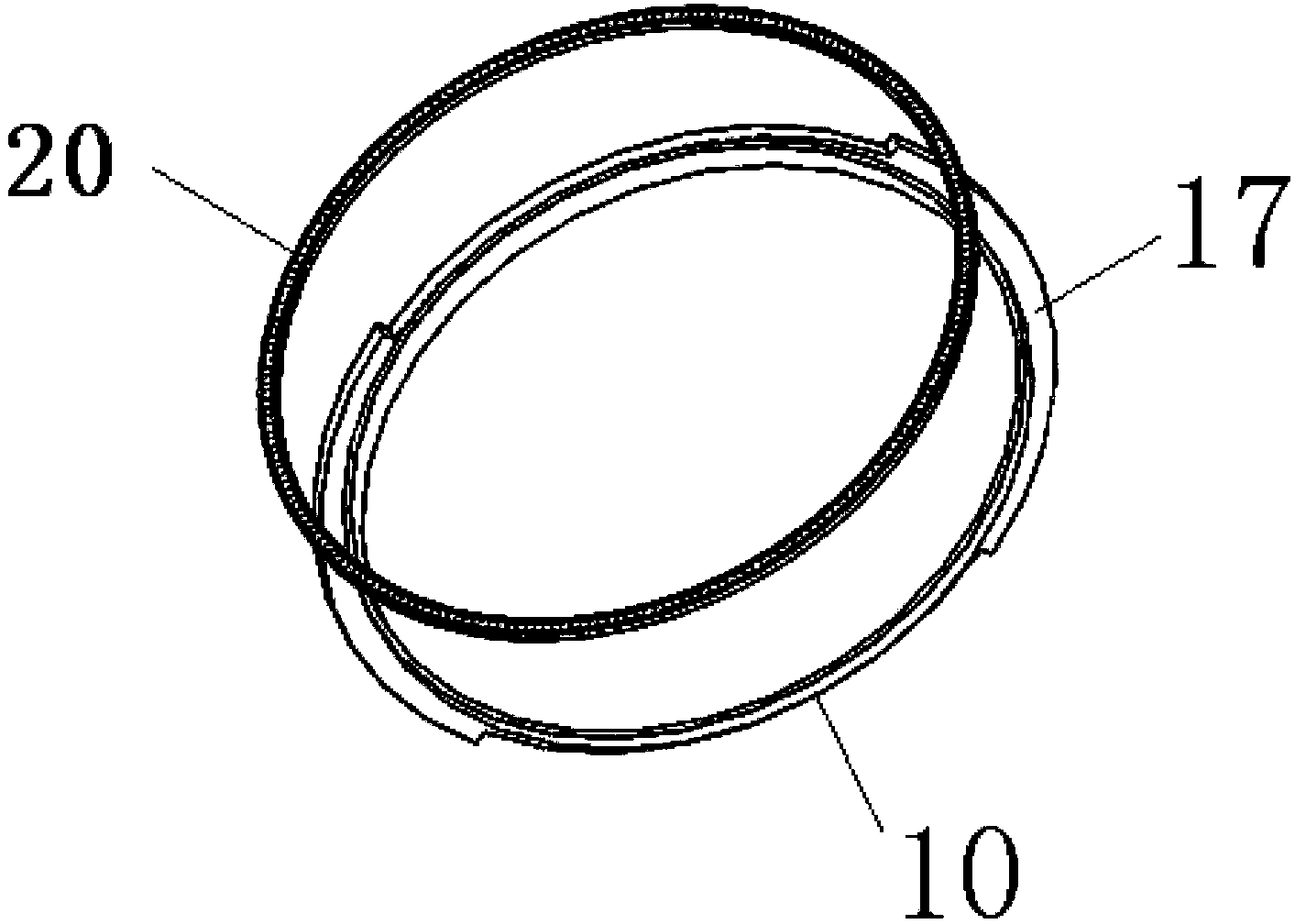

[0032] refer to Figure 1 to Figure 3 , the automatic demoulding machine of the present invention comprises an equipment base 18, two rails 4 are installed in parallel on the equipment base 18, a slider 5 is installed in each rail 4, and a "[" shape is fixedly installed on the two sliders 5. Bracket 3, a punch clamp 6 is installed on the inner wall on both sides of the "["-shaped bracket 3, and two punch clamps 6 are opposite, and one end of the two rails 4 is installed to connect with the "["-shaped bracket 3 The punch fixture driving device is equipped with a rotating device at the other end, and the rotating device includes a rotating driving device, a transmission device and a rotary table 13; wherein, the track in the transmission device is an annular track 10 set on the equipment table, and is a pre-set Leave the space for placing the epoxy resin part after it comes out of the mold. The middle of the ring track 10 is empty, that is, there is a hole slightly larger than t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com