Continuous foam forming system and continuous foam forming method

A foam molding and foaming machine technology, which is applied in the field of sheet metal production, can solve the problems of waiting time and reduce the production efficiency of foam molding system, and achieve the effects of saving waiting time, improving quality and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

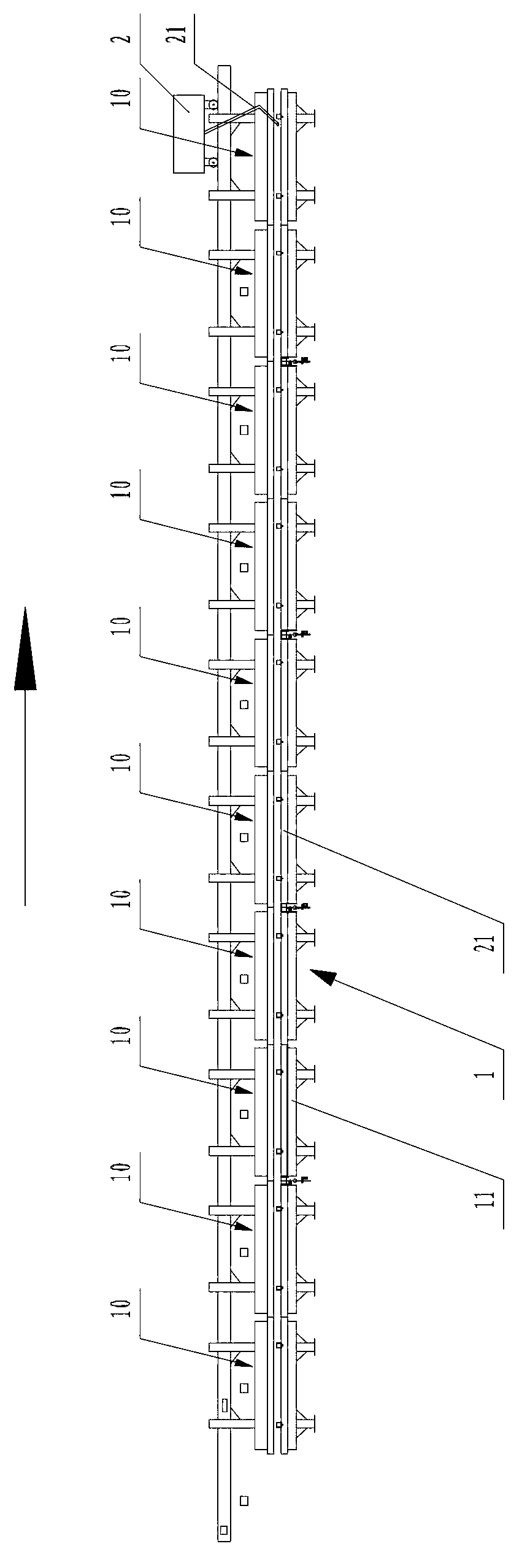

[0048] First stipulate figure 1 The direction of the arrow in is the running direction of the board.

[0049] Such as figure 1 As shown, the continuous foam molding system provided by Embodiment 1 of the present invention includes a foaming table 1 and a foaming machine 2. The foaming machine 2 is provided with a foaming gun 21, and the bottom of the foaming table 1 is provided with a base 11. , the top of the base 11 is provided with a lower template 12, and the foaming table 1 also includes a plurality of compression molding devices 10, and the plurality of compression molding devices 10 are sequentially arranged above the lower template 12 along the board moving direction; the compression molding devices 10 include an upper Formwork, upper formwork pressure device, side formwork and side formwork pressure device, the upper formwork is arranged on the top of the lower formwork 12, and is connected with the upper formwork pressure device, and the side formwork is arranged on...

Embodiment 2

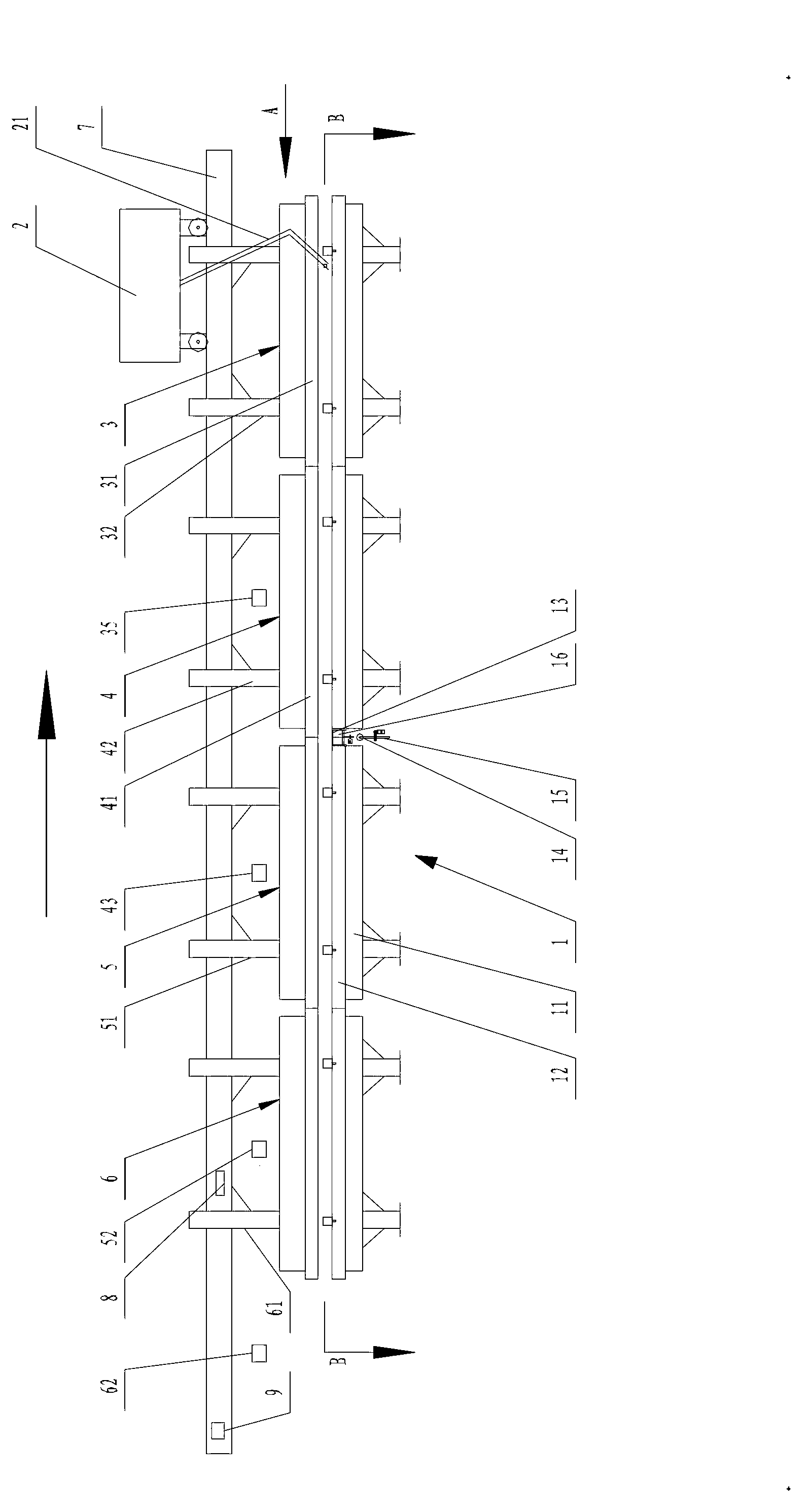

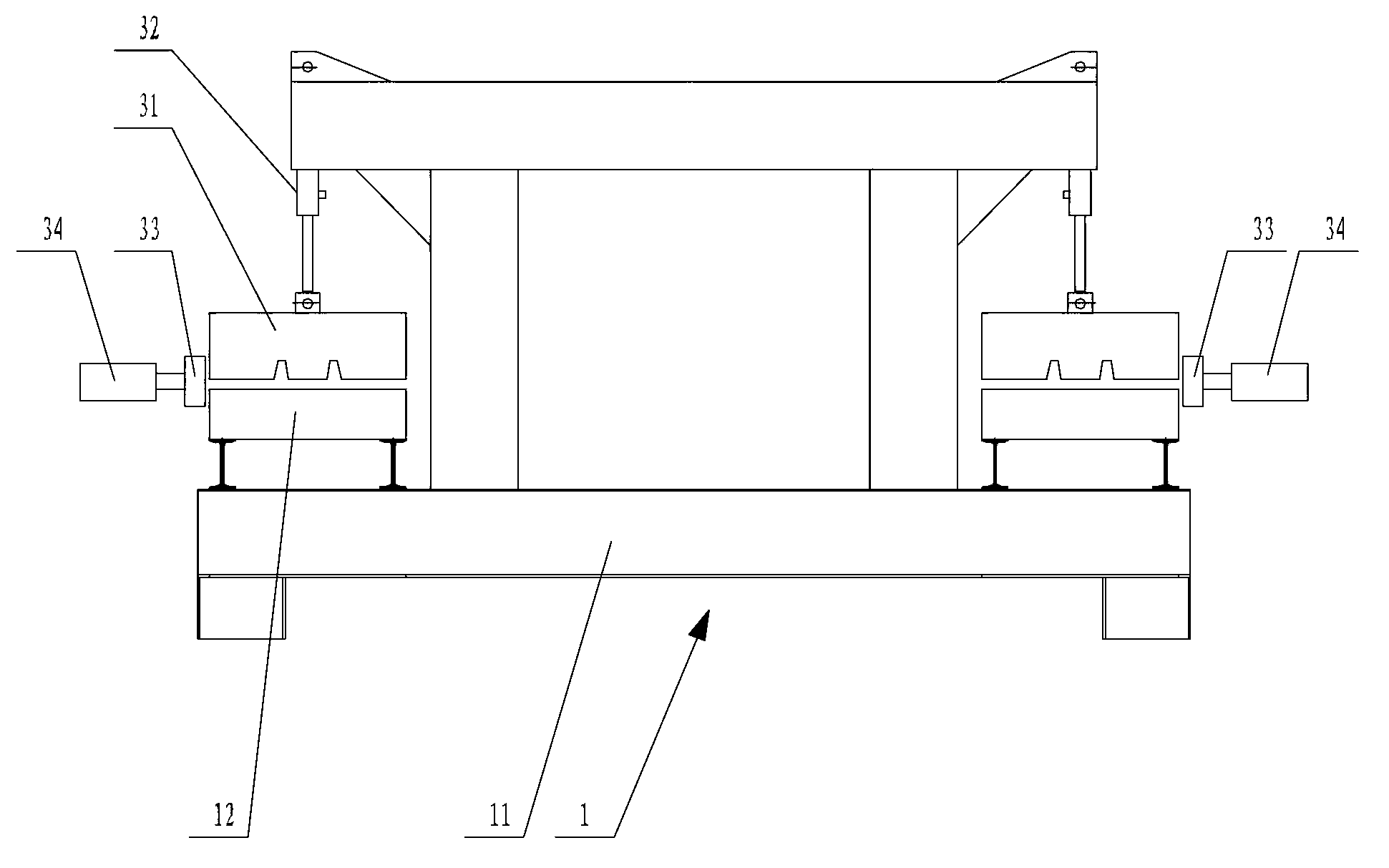

[0052] For ease of description and understanding, the number of compression molding devices is set to four in this embodiment, such as figure 2 As shown, they are respectively the first die device 3, the second die device 4, the third die device 5 and the fourth die device 6, and stipulate figure 2 The direction of the arrow in is the running direction of the board.

[0053] Such as Figure 2 to Figure 4 As shown, the continuous foaming molding system provided by Embodiment 2 of the present invention includes a foaming table 1 and a foaming machine 2. The foaming machine 2 is provided with a foaming gun 21, and the bottom of the foaming table 1 is provided with a base 11. , the top of the base 11 is provided with a lower template 12, and the foaming table 1 also includes a first molding device 3, a second molding device 4, a third molding device 5 and a fourth molding device 6, and along the board's walking board orientation (eg figure 2 (indicated by the middle arrow), ...

Embodiment 3

[0092] Such as Figure 5 As shown, the continuous foam molding method provided by Embodiment 3 of the present invention comprises the following steps:

[0093] Step 201, sending the plate into the foaming station.

[0094] Step 202, using a foaming device to fill the foaming agent between the boards.

[0095] Step 203 , while using the foaming device to fill the foaming agent between the boards, use a plurality of compression molding devices to sequentially perform compression molding on the parts filled with the foaming agent between the boards.

[0096] It can be realized by the continuous foam molding system provided in the above-mentioned embodiment 2, and its specific working process is the same as the working process described in the second embodiment, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com