Automatic part charging device of automobile welding production line

A welding production line and production line technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment and other directions, can solve the problems that the automatic loading device cannot adapt, reduce the labor intensity of operators, and the labor intensity of operators is high, and achieves a simple exchange process. The effect of fast, avoiding crowding of the venue and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

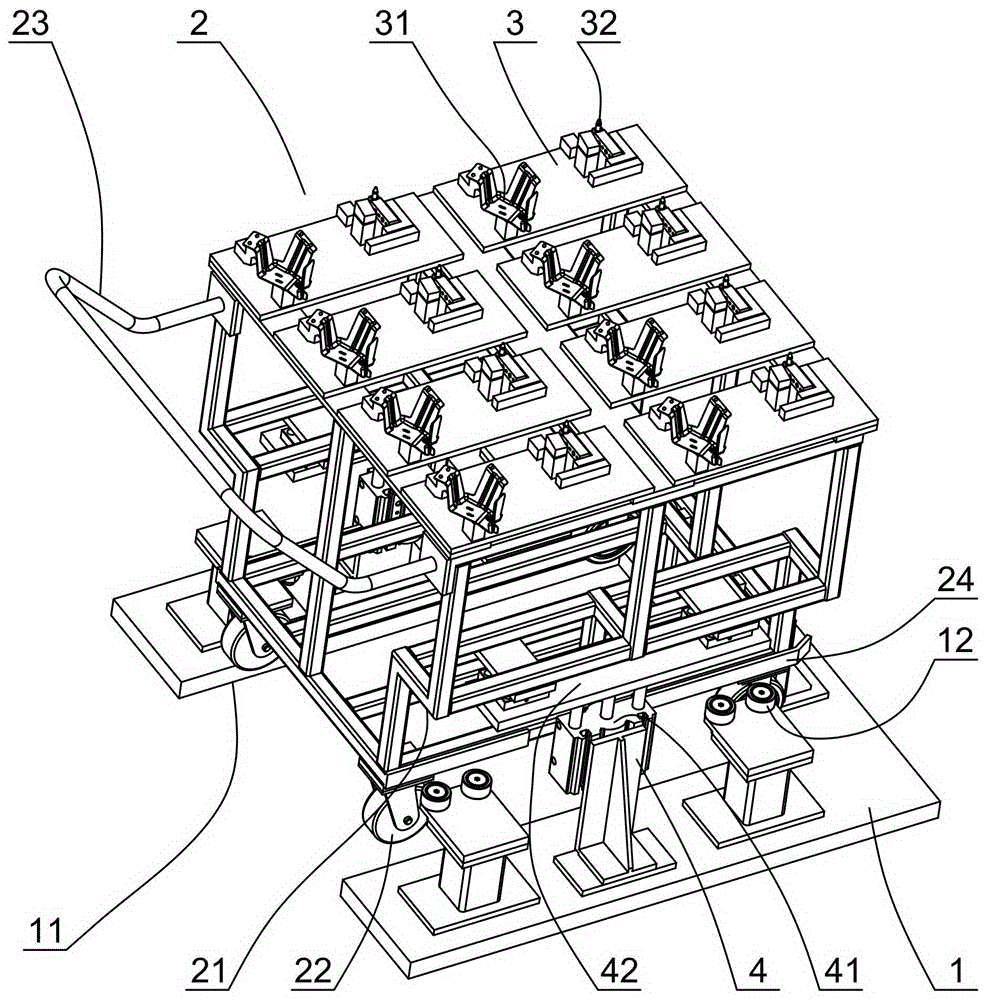

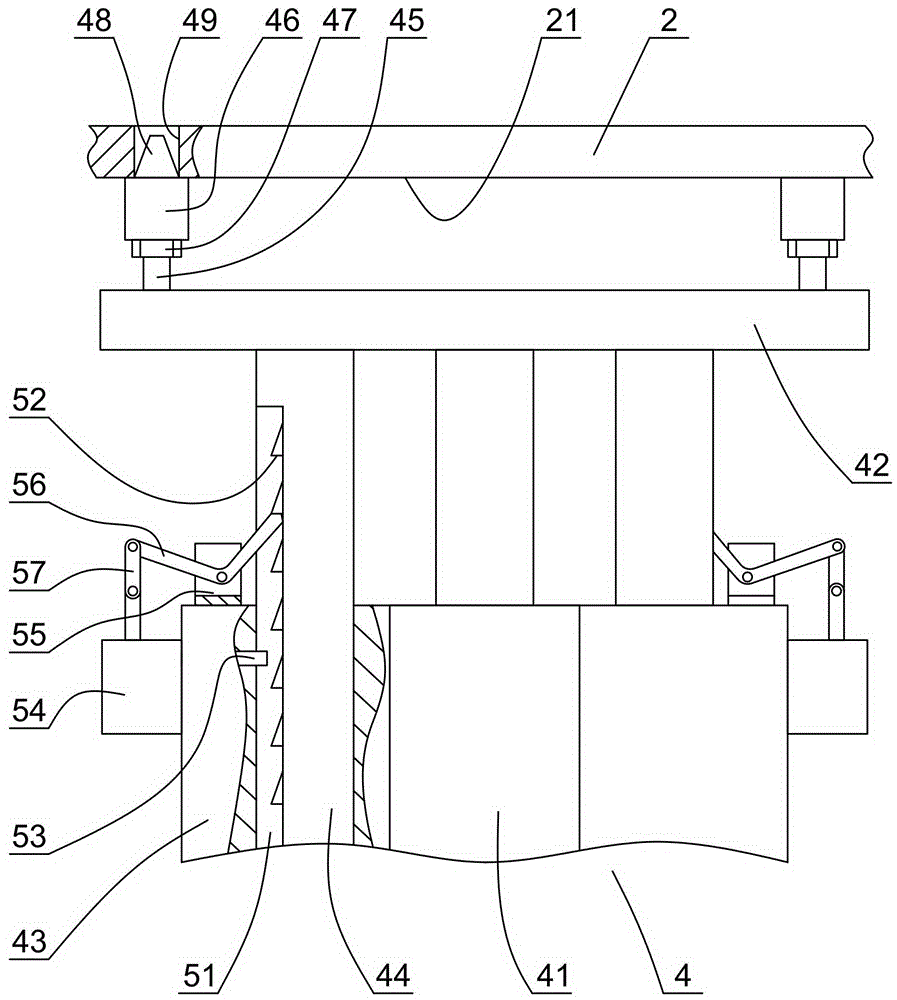

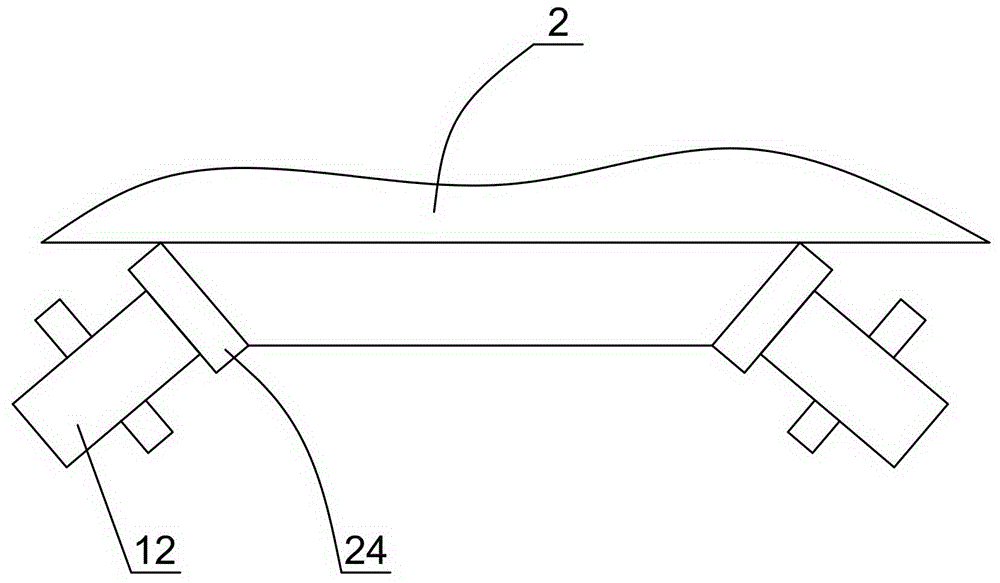

[0024] Embodiment 1: as figure 1 As shown, the automatic loading device of a kind of automobile welding production line of the present invention is applicable to the loading of robot welding production line, comprises base 1, movable material rack 2, and material rack is a rectangular parallelepiped frame structure, and material rack The bottom of the bottom shrinks inward on both sides in the length direction to form steps, making its cross-section in an inverted convex shape, and the horizontal planes at the steps on both sides constitute the supporting surfaces 21 on both sides of the lower part of the material rack. The four corners of the bottom that shrink inward Four universal wheels 22 are housed at the place, and a handrail 23 is set on the rear side in the width direction to facilitate its implementation. There are 8 workpiece positioning brackets 3 arranged on the top surface of the outwardly expanded upper part of the material rack, and the 8 workpiece positioning ...

Embodiment 2

[0031] Embodiment 2: The automatic loading device of a kind of automobile welding production line of the present invention is suitable for the loading of robot welding production line, and its basic structure is the same as that of Embodiment 1, referring to the attached figure 1 , including the base, 1. Movable material rack 2. The material rack is a rectangular frame structure. The horizontal plane at the step constitutes the supporting surfaces 21 on both sides of the lower part of the material shelf, and four universal wheels 22 are installed at the four corners of the bottom that shrinks inward, and an armrest 23 is set on one side of the width direction to facilitate its implementation. . Such as Figure 4 As shown, a turntable 25 is horizontally arranged on the top surface of the outwardly expanded upper part of the material rack, and the turntable is driven by a stepping motor (not shown in the figure) to accurately control its rotation angle. Eight workpiece positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com