Novel container handling system

A technology for loading and unloading systems and containers, applied in storage devices, transportation and packaging, etc., can solve the problems of increased port operating costs, high design and manufacturing costs, and low degree of automation, so as to save port construction costs, reduce operators, and improve operations. The effect of efficiency

Inactive Publication Date: 2013-04-03

WUHAN UNIV OF TECH

View PDF3 Cites 23 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the relay link in these container handling systems is container truck transportation, which uses fuel power, which causes environmental pollution and increases port operating costs; secondly, the degree of automation of this container truck transportation mode is not high. There are inevitable safety hazards in the deployment of operators; and AGV technology is a high-tech integration of light, machinery, and electricity. Although it is revolutionary in terms of automation, it not only requires high technical content, but also has high design and manufacturing costs. It is expensive, and has high requirements for related port supporting facilities, which requires overall planning, system design and unified implementation. Therefore, the construction cost of the entire system is greatly increased compared with traditional ports. At present, there are few applications of this technology at home and abroad.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

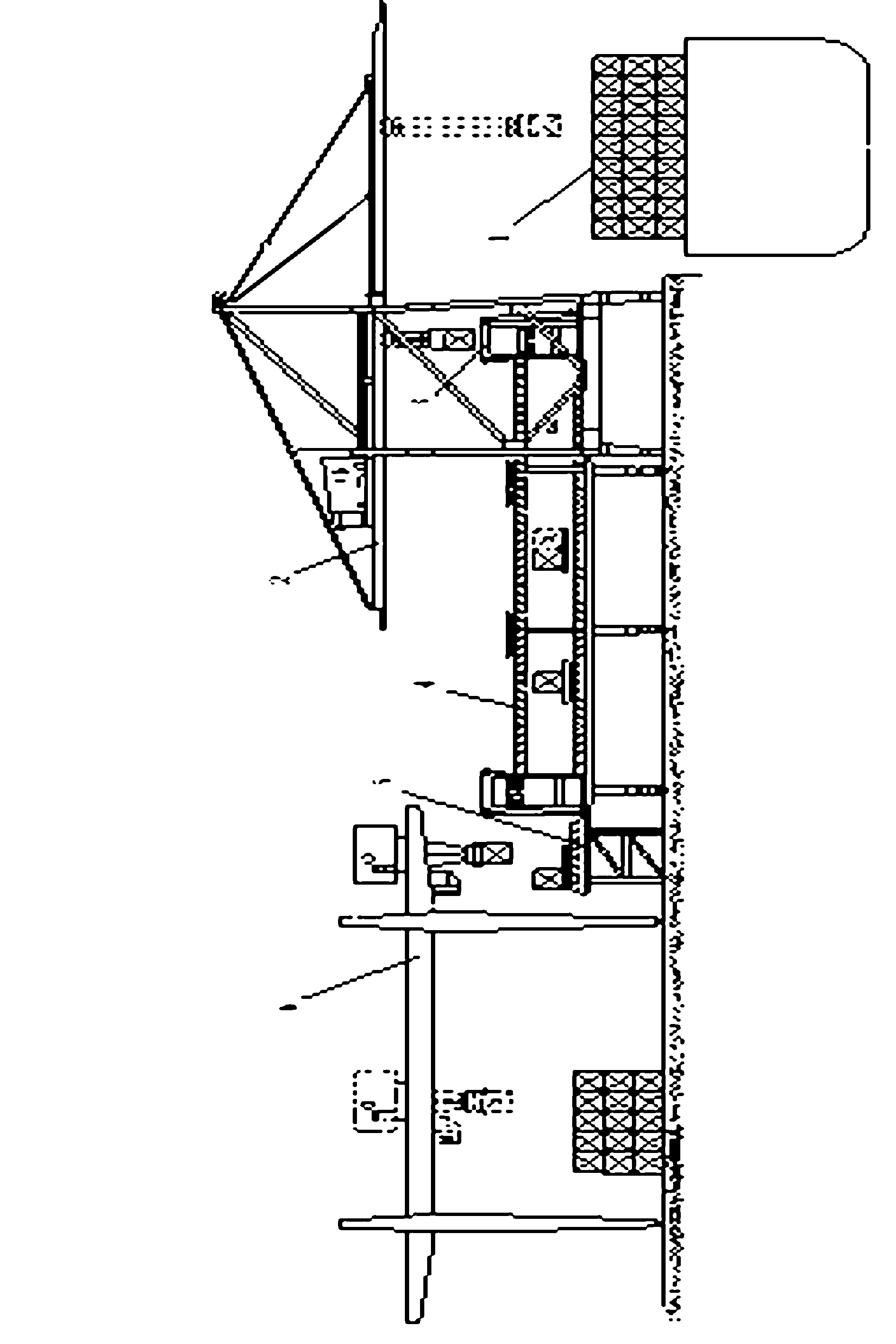

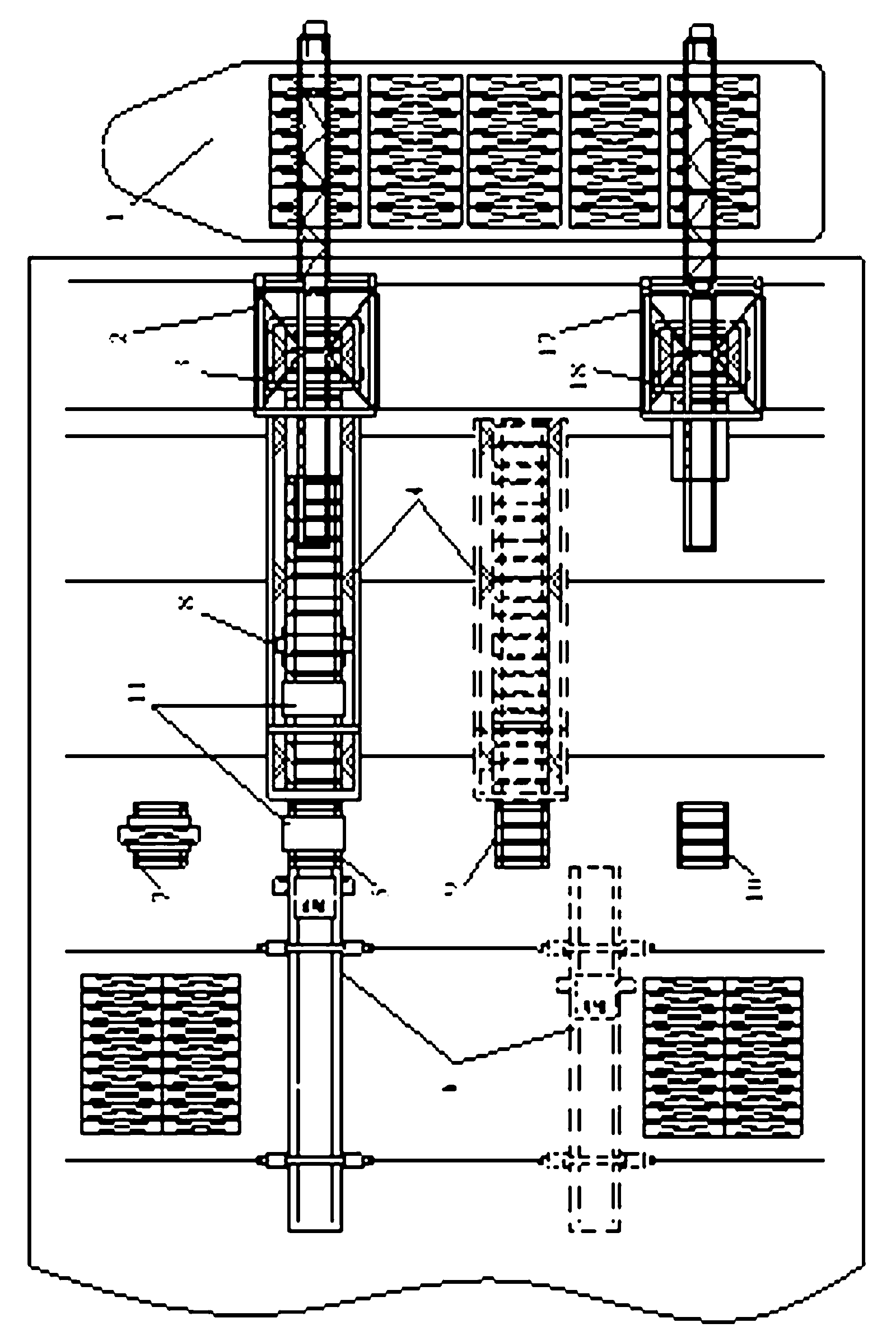

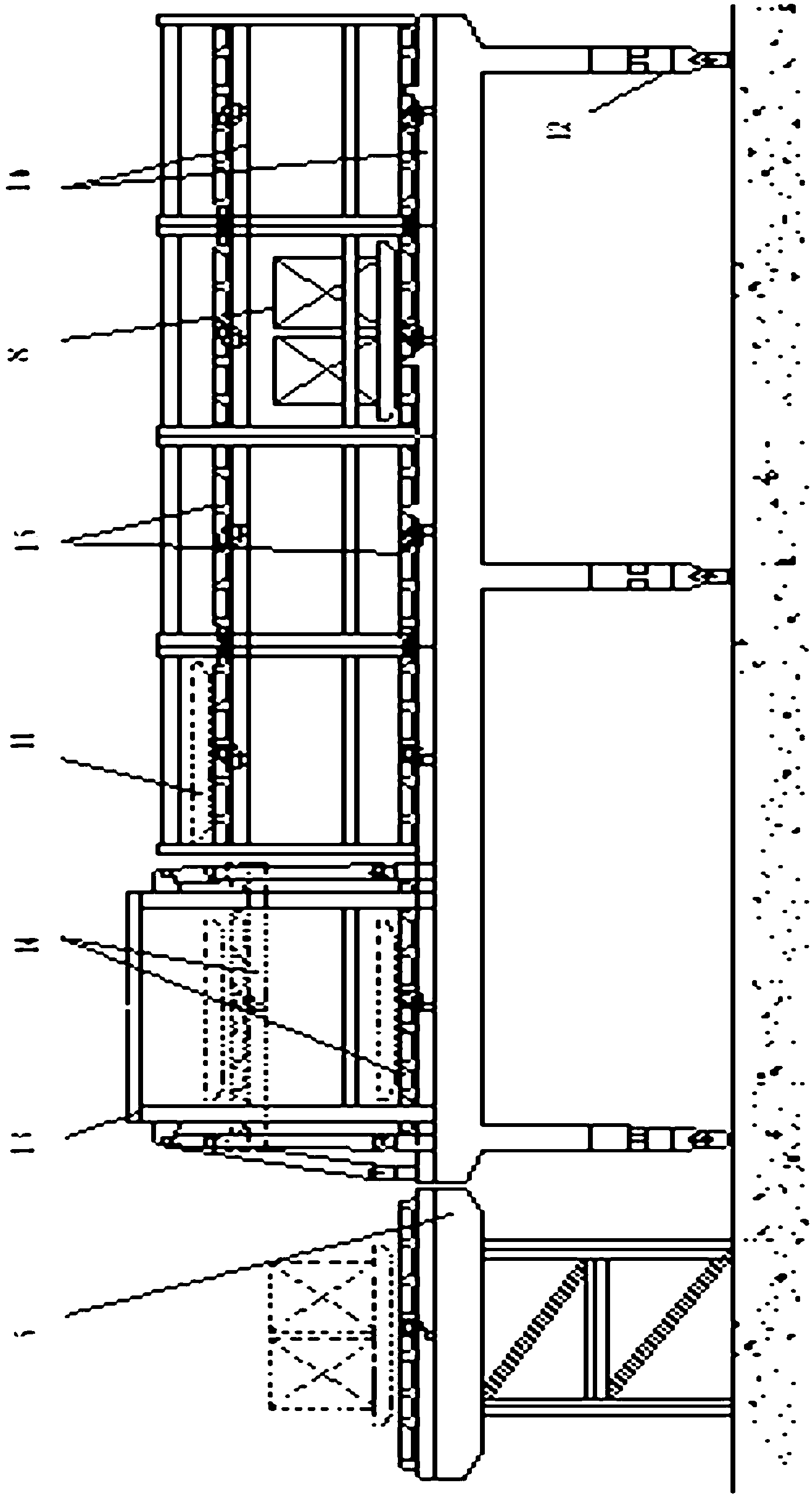

The invention provides a novel container handling system, which comprises a shoreside container handling machine, a track movable relay conveyor, a fixed vertical lifting mechanism, a fixed trestle bridge and a storage yard container handling machine. The shoreside container handling machine is positioned at wharf at the front edge; the fixed vertical lifting mechanism is fixed in a door frame of the shoreside container handling machine; the track movable relay conveyor is positioned between the fixed trestle bridge and the shoreside container handling machine; and the fixed trestle bridge is positioned between the operation region of the relay conveyor and the operation region of the storage yard container handling machine. By the system, the operation efficiency of middle-small size harbors wharves can be improved; the relay links during transportation adopts a continuous conveyor, so the container handling system can normally work under server natural conditions; the construction cost of ports is saved; the conversion from traditional container truck transportation by adopting fuel power to the operation means of continuous conveyor driven by power is realized; the energy consumption is reduced; and the environment is protected. The first-line operating people are reduced; the safety of the whole system is improved; and the system is suitable for handling the container of middle-small sized harbors wharves.

Description

technical field [0001] The invention relates to a port container loading and unloading process, in particular to a novel container loading and unloading system suitable for small and medium-sized port terminals in inland rivers. Background technique [0002] Containerized transportation has gradually become the main means of current logistics transportation. The domestic port container transportation industry is developing rapidly, and the container handling machinery and handling technology are also constantly updated, which puts forward new requirements for the economic performance and environmental performance of the port terminal. At present, the container loading and unloading systems adopted by container ports at home and abroad mainly include: 1. Bridge crane-container truck-gantry crane-container truck; 2. Bridge crane-container forklift-container truck; 3. Portal crane-container Truck - Gantry Crane - Container Truck; 4. Portal Crane - Container Forklift - Contain...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B65G63/00

Inventor 王贡献王名汉曾令烈陈杰李勇智袁建明

Owner WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com