Yarn winding machine and yarn winding unit

A winding machine and yarn technology, applied in the field of yarn splicing devices, can solve problems such as thread breakage, and achieve the effect of improving the freedom of layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

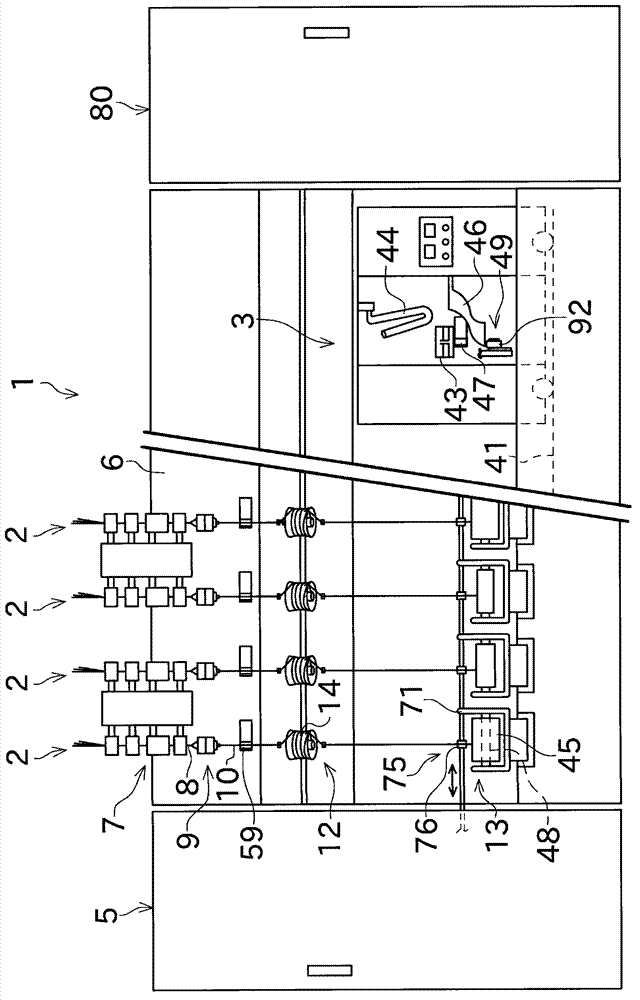

[0042] Next, a spinning machine as a yarn winding machine according to an embodiment of the present invention will be described with reference to the drawings. figure 1 The illustrated spinning machine (spinning machine) 1 has a plurality of spinning units (yarn winding units) 2 arranged side by side, a yarn splicing cart 3, a fan box 80, and a motor box 5.

[0043] A negative pressure source (not shown) and the like for supplying negative pressure to each spinning unit 2 are arranged in the fan box 80. A driving source common to each spinning unit 2 is arranged in the motor housing 5.

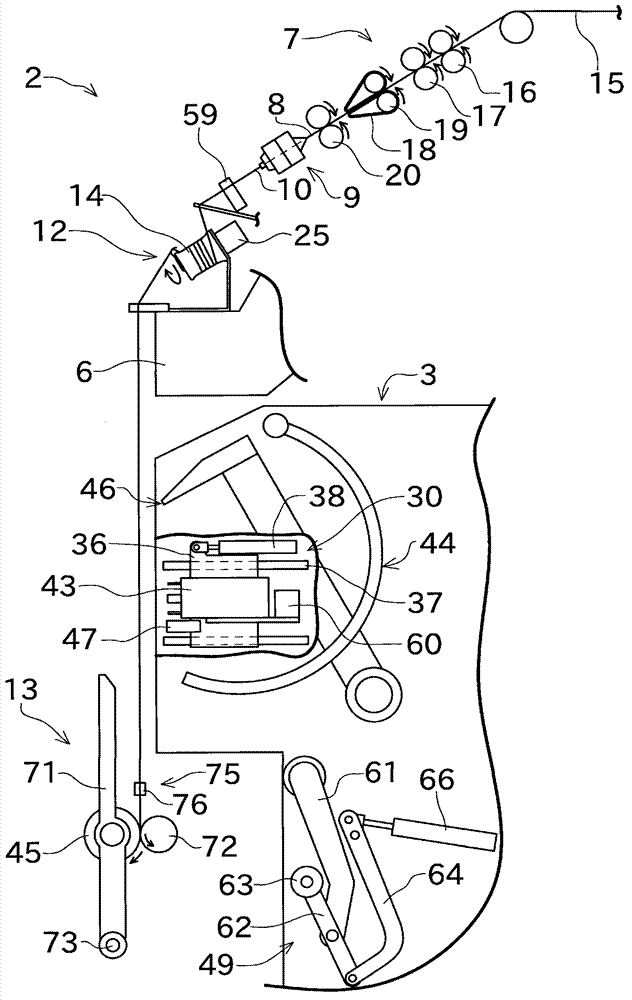

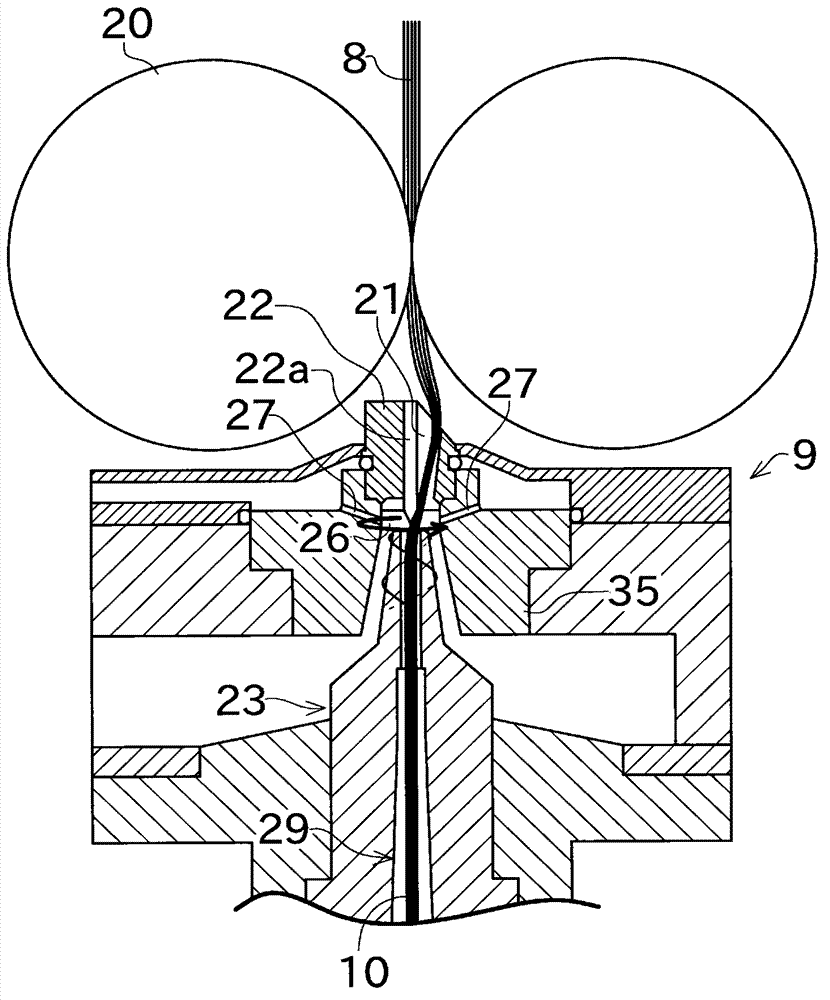

[0044] Such as figure 2 As shown, each spinning unit 2 has as a main structure: a drafting device 7, a spinning device (yarn feeding section) 9, a yarn accumulating device 12, and a winding device (winding section) arranged in order from upstream to downstream. ) 13. Each spinning unit 2 spins the fiber bundle 8 sent from the drafting device 7 by the spinning device 9 to produce the spun yarn 10,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com