Full-automatic double-end looping wire-rewinding machine

A fully automatic, wire take-up technology, applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., can solve the problems of wire quality stability, high labor intensity, low production efficiency, etc., to save resources , high degree of automation, and convenient packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

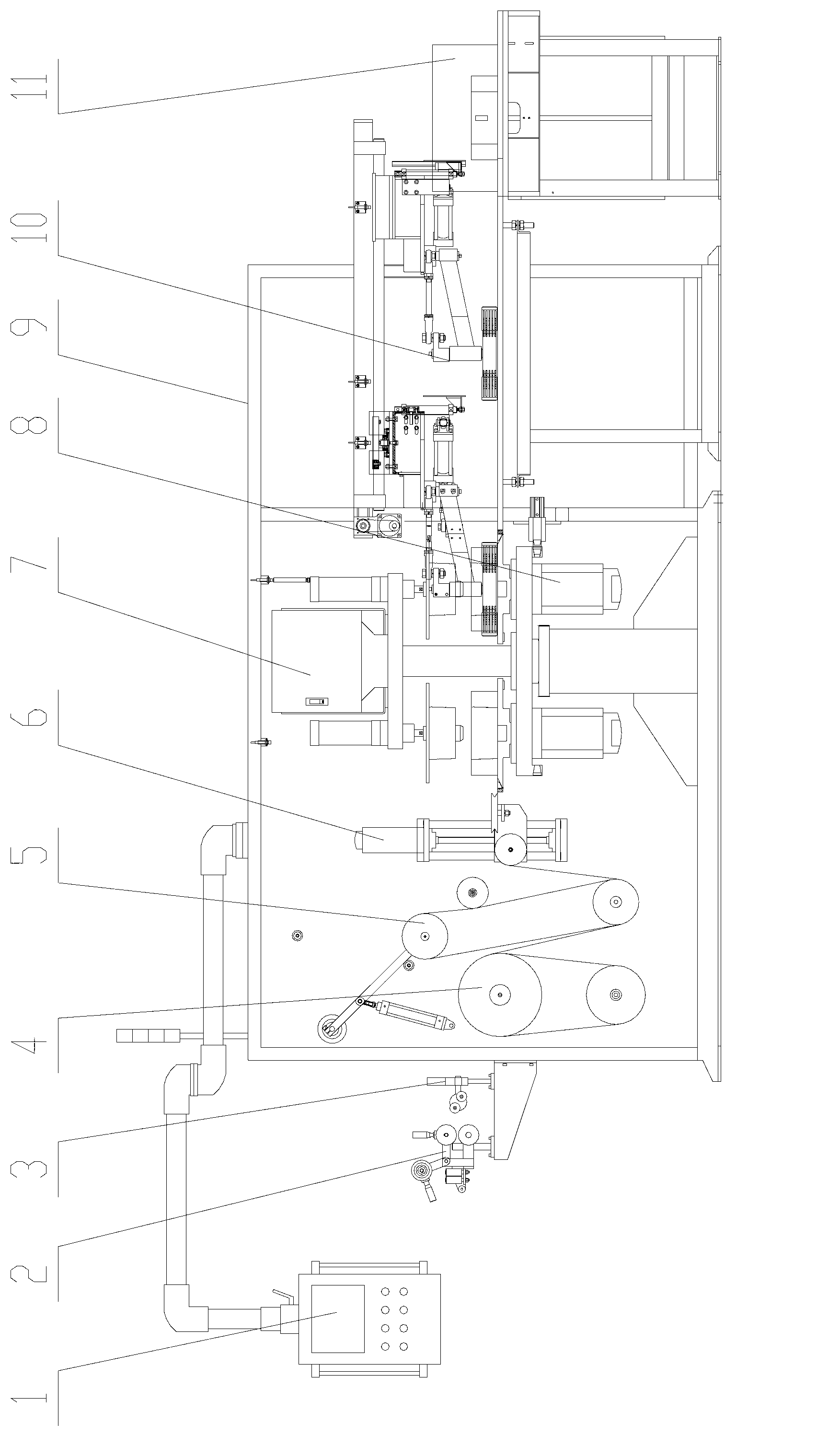

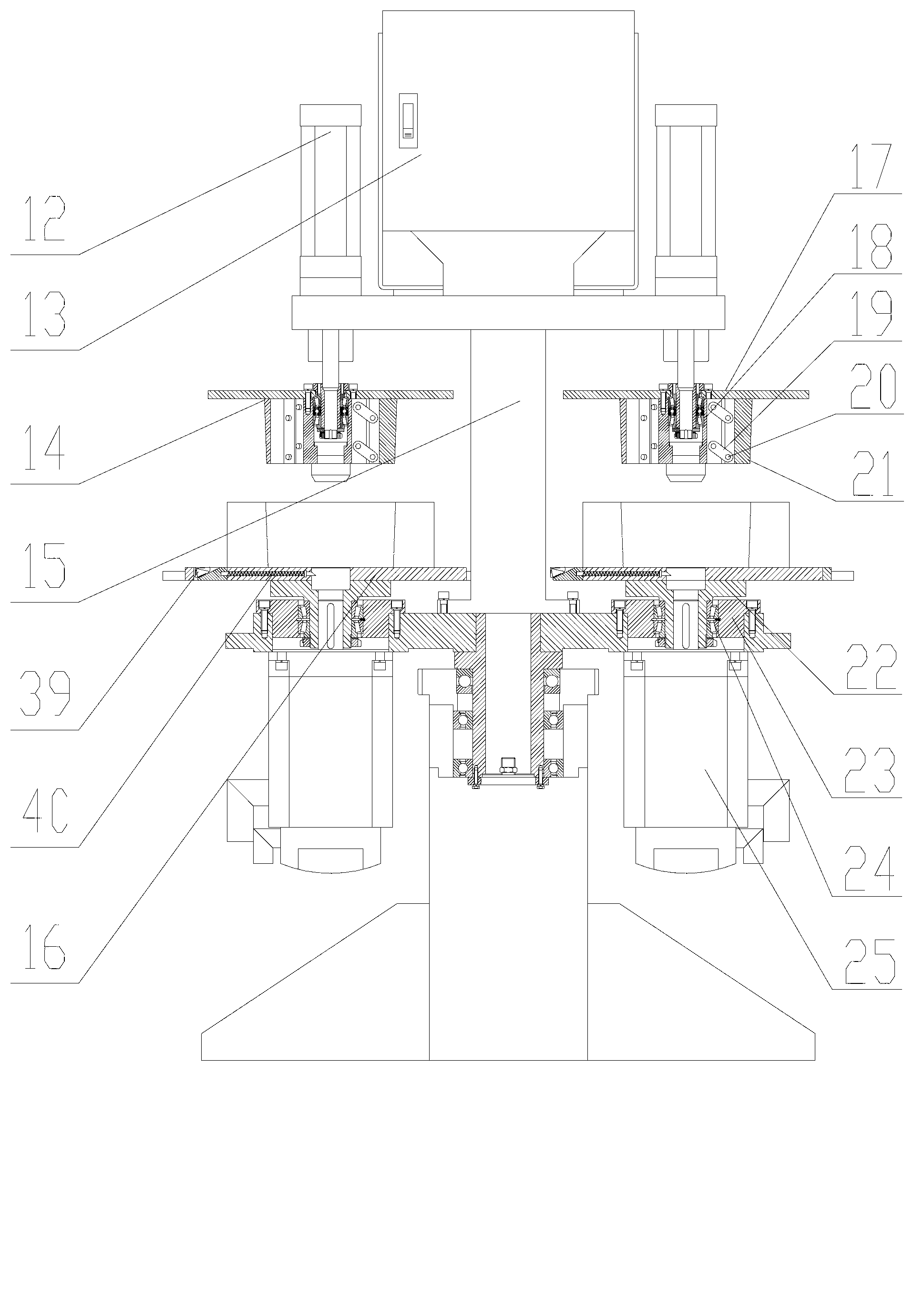

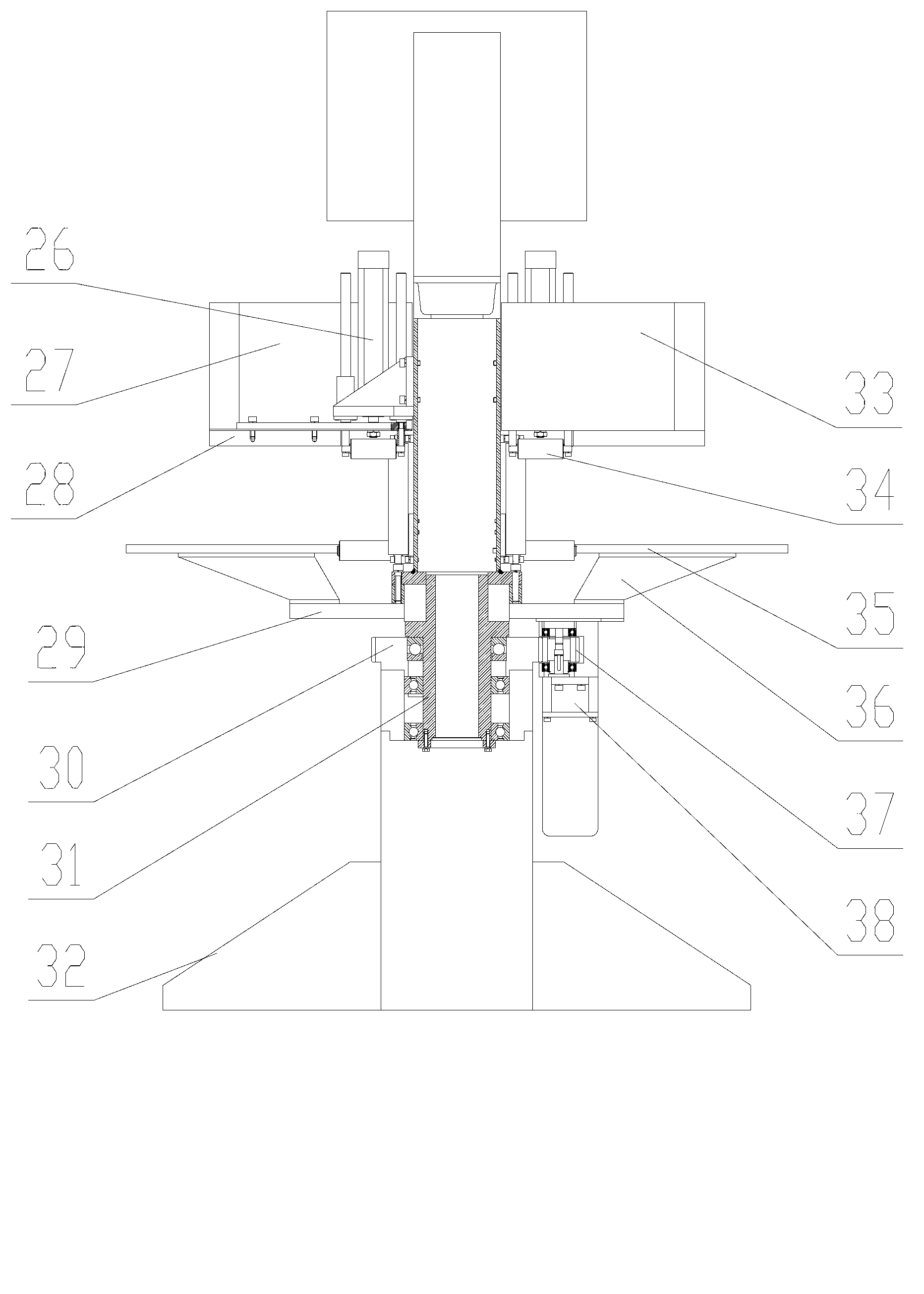

[0024] like figure 1 As shown, a kind of full-automatic double-head loop forming wire take-up machine described in the embodiment of the present invention includes a frame 9, one side of the frame 9 is provided with a fully automatic cable tie machine 11, and the other side of the frame 9 An operation table 1, a wire clamping device 3 and a meter counting device 2 are arranged on the side, and a double-head loop forming system 7 is arranged on the frame 9, and two loop forming power devices 8 are arranged symmetrically on the bottom of the double-head loop forming system 7, and the double loop forming power devices 8 are arranged symmetrically on the bottom of the double loop forming system 7. One side of the head knitting system 7 is provided with a manipulator 10, the other side of the double-head knitting system 7 is provided with a cable arrangement 6, one side of the cable arrangement 6 is provided with a traction device 4, and the cable arrangement 6 and the traction devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com