High-pressure-tolerant slow-leakage-rate gasket material for beer bottle cap and preparation method of material

An air leakage rate and bottle cap technology, applied in the field of food packaging materials, can solve the problems of undiscussed related properties, migration, and limited compatibility, and achieve the effects of low chronic air leakage rate, easy control, and high pressure resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

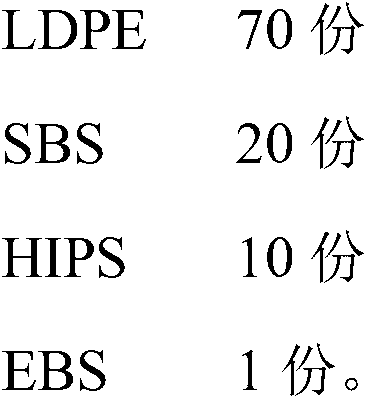

Embodiment 1

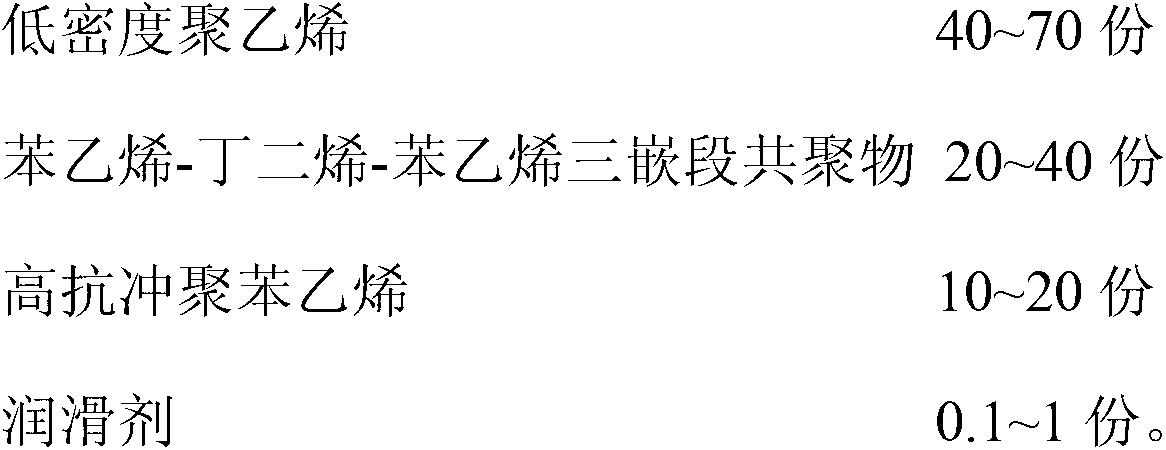

[0030] Gasket material with high pressure resistance and low chronic air leakage rate for beer bottle caps, its raw material composition and parts by weight are as follows:

[0031]

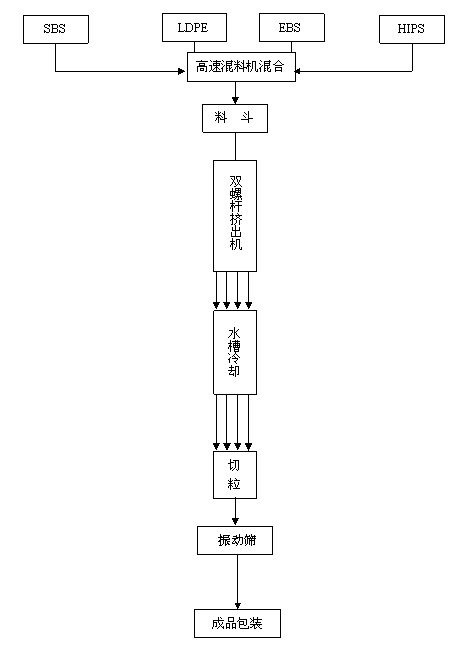

[0032] The preparation method of above-mentioned pad material, comprises the steps:

[0033] ① Add the SBS raw material to the high-speed batch mixer, add LDPE, HIPS and EBS at the same time, mix and stir for 5 minutes to obtain the premix;

[0034] ②Place the mixed premixed material in a parallel co-rotating twin-screw extruder to melt and extrude it, and then granulate it.

[0035] The parallel co-rotating twin-screw extruder has seven temperature control zones, among which, the temperature of the first zone is 150°C, the temperature of the second zone is 170°C, the temperature of the third zone is 185°C, the temperature of the fourth zone is 185°C, the temperature of the fifth zone is 185°C, and the temperature of the sixth zone is 185°C. The zone temperature is 185°C, the seventh zone tem...

Embodiment 2

[0038] Gasket material with high pressure resistance and low chronic air leakage rate for beer bottle caps, its raw material composition and parts by weight are as follows:

[0039]

[0040]

[0041] The preparation method of above-mentioned pad material, comprises the steps:

[0042] ① Add the SBS raw material to the high-speed batch mixer, add LDPE, HIPS and EBS at the same time, mix and stir for 5 minutes to obtain the premix;

[0043] ②Place the mixed premixed material in a parallel co-rotating twin-screw extruder to melt and extrude it, and then granulate it.

[0044] The parallel co-rotating twin-screw extruder has seven temperature control zones, among which, the temperature in the first zone is 155°C, the temperature in the second zone is 175°C, the temperature in the third zone is 190°C, the temperature in the fourth zone is 190°C, the temperature in the fifth zone is 190°C, and the temperature in the sixth zone is 190°C. The zone temperature is 190°C, the seve...

Embodiment 3

[0047] Gasket material with high pressure resistance and low chronic air leakage rate for beer bottle caps, its raw material composition and parts by weight are as follows:

[0048]

[0049] The preparation method of above-mentioned pad material, comprises the steps:

[0050] ① Add the SBS raw material to the high-speed batching mixer, add LDPE, HIPS and EBS at the same time, mix and stir for 10 minutes to obtain the premix;

[0051] ②Place the mixed premixed material in a parallel co-rotating twin-screw extruder to melt and extrude it, and then granulate it.

[0052] The parallel co-rotating twin-screw extruder has seven temperature control zones, among which, the temperature in the first zone is 155°C, the temperature in the second zone is 175°C, the temperature in the third zone is 190°C, the temperature in the fourth zone is 190°C, the temperature in the fifth zone is 190°C, and the temperature in the sixth zone is 190°C. The zone temperature is 190°C, the seventh zone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com