Patents

Literature

65 results about "Styrene-butadiene-styrene triblock copolymer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Adhesive blends for styrene polymers and articles

InactiveUS20070071988A1Improve adhesionWell formedSynthetic resin layered productsThin material handlingPolymer sciencePolymer resin

Owner:EQUSR CHEM LP

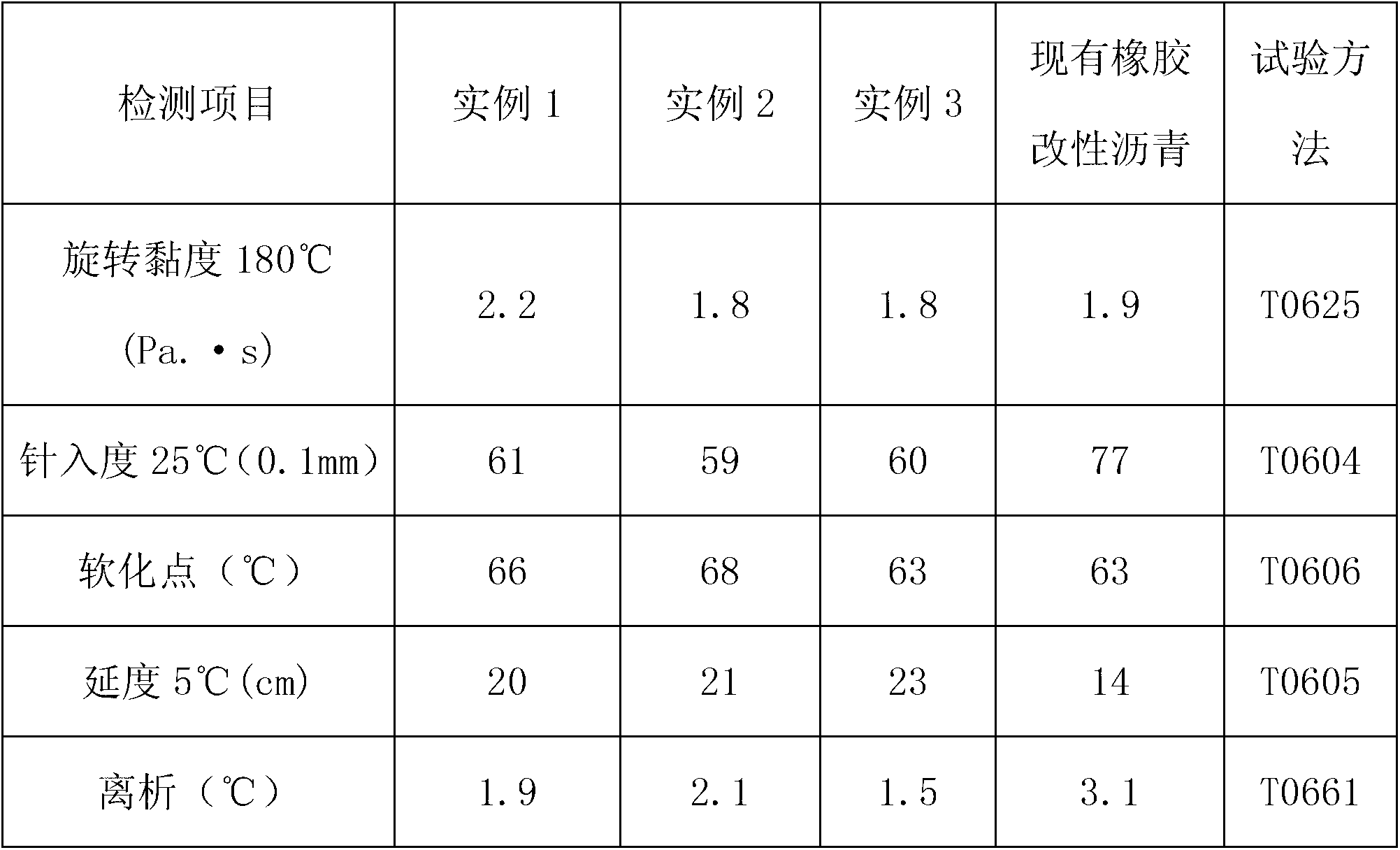

Rubber powder-modified asphalt and preparation method thereof

ActiveCN103073903AFix stability issuesSolve the phenomenon of easy segregationBuilding insulationsSulfurStyrene-butadiene-styrene triblock copolymer

The invention belongs to the technical field of materials for road works, and discloses rubber powder-modified asphalt and a preparation method thereof. The rubber powder-modified asphalt consists of the following components: 100 parts by weight of petroleum asphalt, 15 to 30 parts by weight of rubber powder, 0.5 to 2 parts by weight of styrene-butadiene-styrene triblock copolymer, 2 to 5 parts by weight of aromatic oil, 0.5 to 2 parts by weight of maleic anhydride polymer and 1 to 3 parts by weight of sulfur. The preparation method for the rubber powder-modified asphalt includes the following steps: the petroleum asphalt is heated to 150 DEG C to 170 DEG C, the rubber powder is then added into the petroleum asphalt and mixed, the styrene-butadiene-styrene triblock copolymer, the aromatic oil, the maleic anhydride polymer and the sulfur are added into the mixture after uniform mixture is finished, the mixture is sheared by a shearing machine, and is swelled under an environment with the temperature of 130 DEG C to 150 DEG C for 12 to 18 hours, and therefore the rubber powder-modified asphalt is obtained.

Owner:XIAN HIGHWAY INST

Asphalt composition containing styrene-butadiene-styrene block copolymer having asymmetric polystyrene block

InactiveUS20060241218A1Improve ductilityImprove thermal stabilityIn situ pavingsPolymer sciencePolystyrene

The present invention provides a modified asphalt composition showing excellent ductility and thermal stability at low temperature and the resistance to permanent deformation at high temperature comprising i) 100 wt. part of natural asphalt; and ii) 0.5˜40 wt. part of asymmetric styrene-butadiene-styrene triblock copolymer having number average molecular weight of 20,000˜1,000,000. Modified asphalt composition of present invention can be used for pavement of road or manufacturing water proof sheet.

Owner:KOREA KUMHO PETROCHEMICAL CO LTD

Process for forming multilayer structures containing a metal layer

InactiveUS20120196138A1Layered product treatmentSynthetic resin layered productsContact timeAcid derivative

A process for producing a multilayer structure comprising:contacting an adhesive layer having a first side and a second side, on its first side with a metal layer having a first side and a second side, on its first side at a temperature of 325° F. to 425° F. for a contact time of 0.5 to 5.0 seconds, thereby adhering the adhesive layer to the metal layer. The adhesive layer comprises an ethylene-C4-8 α-olefin linear low density copolymer; a polymer grafted with an ethylenically unsaturated carboxylic acid or acid derivative; and a styrene-butadiene-styrene triblock copolymer having an MI of 5 to 50.

Owner:EQUSR CHEM LP

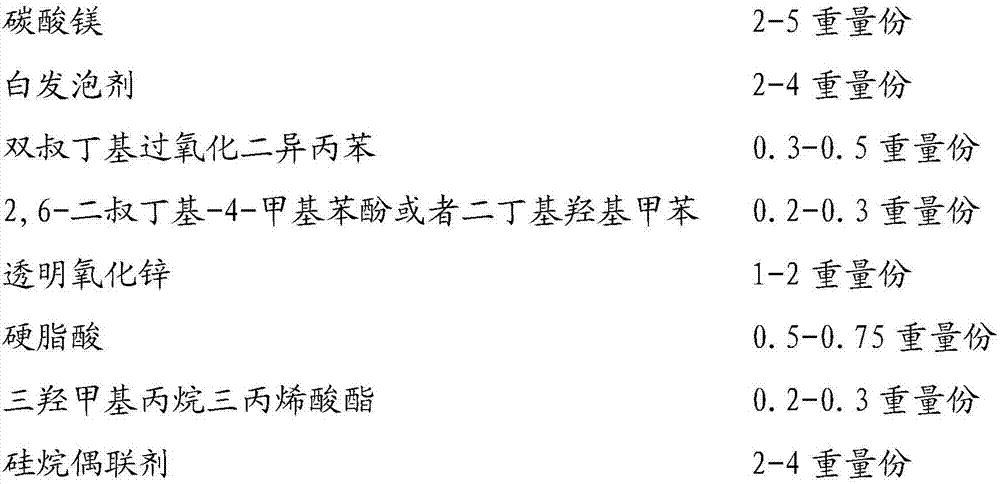

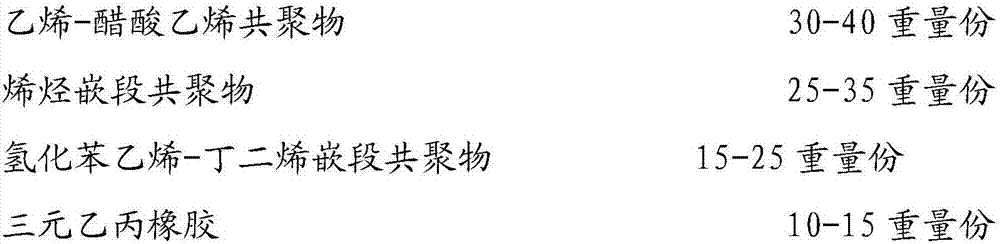

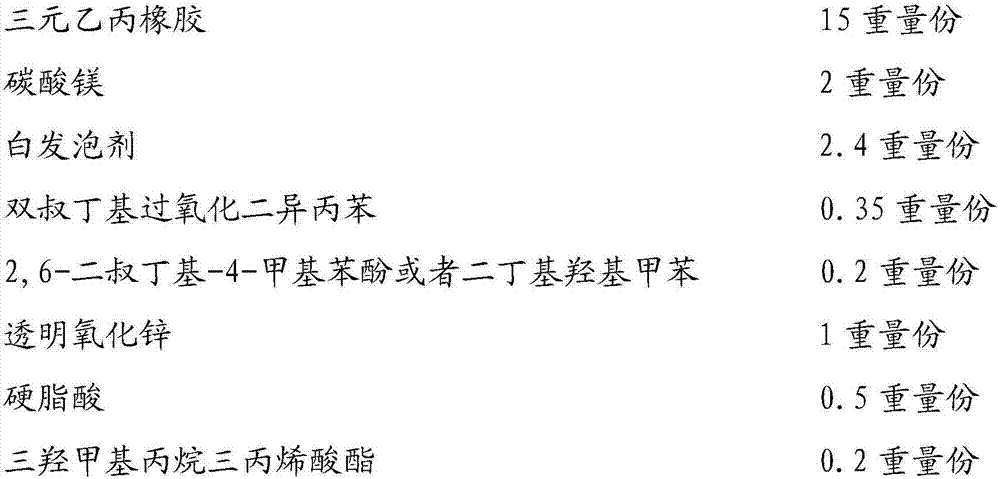

Transparent foam sole formulation and method of using formulation to make sole

ActiveCN107501713AGood flexibilityImprove blending effectSolesPolymer scienceButylated hydroxytoluene

The invention relates to a transparent foam sole formulation, made from magnesium carbonate, a white foaming agent, bis(tert-butylperoxy) diisopropyl benzene, 2,6-di-tert-butyl-4-methylphenol or butylated hydroxytoluene, transparent zinc oxide, stearic acid, trimethylolpropane triacrylate, silane coupling agent, ethylene-vinyl acetate copolymer, olefin block copolymer, styrene-butadiene-styrene triblock copolymer, and ethylene-propylene-diene monomer rubber, wherein the magnesium carbonate is powdery and has particle size of 40-80 mesh. A sole made by comprehensively selecting formulations and processes is pervious to light, and can meet the requirements of soles in terms of physical parameters such as elasticity, yellowing resistance, and compression set deformation.

Owner:XTEPCHINA

Iron-adhesive highway asphalt and preparation method thereof

The invention discloses an iron-adhesive highway asphalt which is prepared from the following components in parts by weight: 20-40 parts of 90# matrix asphalt, 3-10 parts of styrene-butadiene-styrene triblock copolymer, 3-10 parts of aromatic oil, 2-5 parts of aviation kerosene, 5-10 parts of machine oil, 10-20 parts of rubber, 2-5 parts of terpene resin, 1-5 parts of organic acid, 2-5 parts of adhesive elastomer material, 5-15 parts of kaolin, 3-7 parts of APAO, 2-5 parts of polyethylene and 0.5-2 parts of phosphoric acid. The iron-adhesive highway asphalt has the advantages of low temperature resistance, no embrittling at low temperature, high adhesive force for steel surfaces, and excellent water resistance, and is suitable for cold areas.

Owner:辽宁瑞德公路科技有限公司

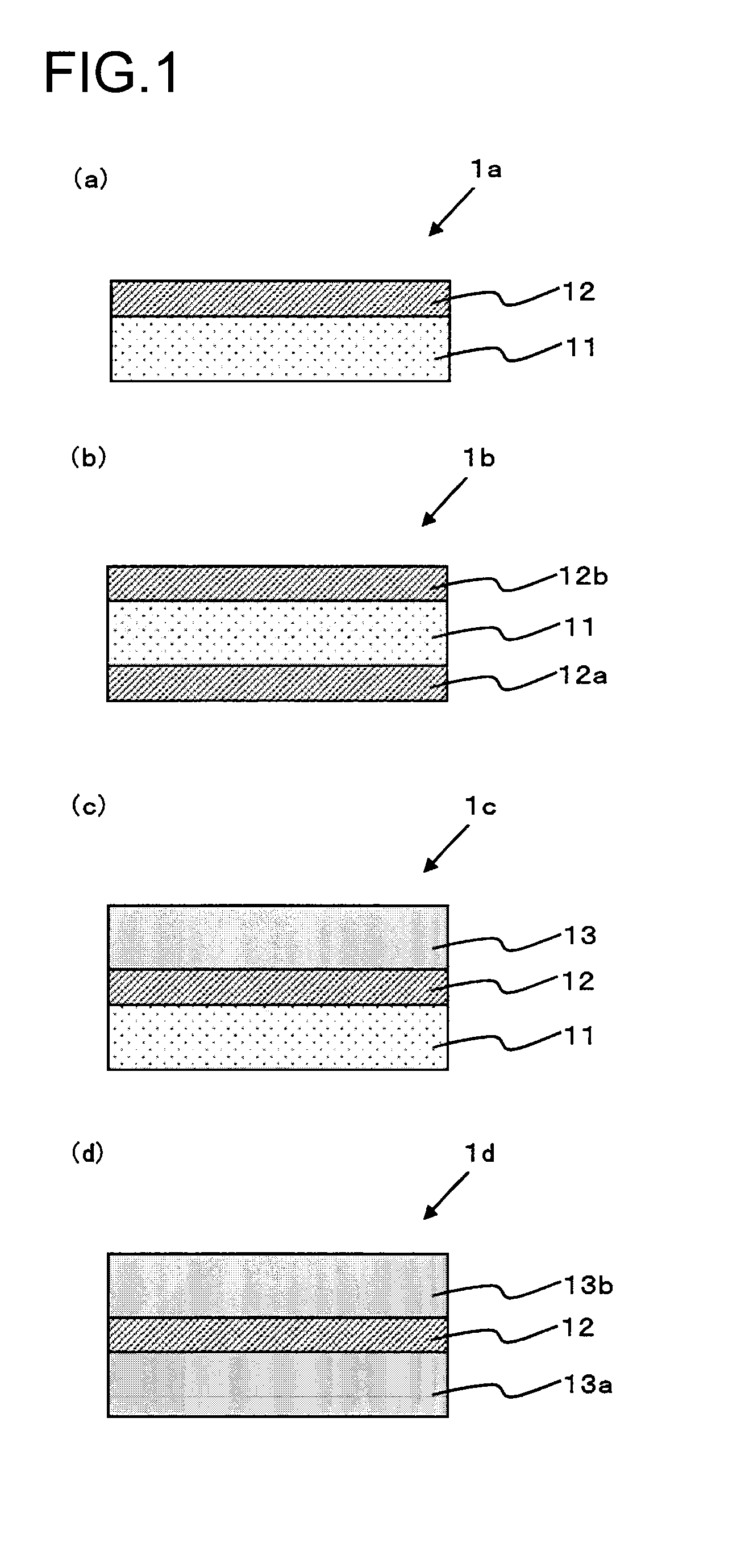

Adhesive agent composition and adhesive sheet

ActiveCN104718263AImprove adhesionHigh transparencyNon-macromolecular adhesive additivesFilm/foil adhesivesStyrene-butadiene-styrene triblock copolymerTackifier

An adhesive sheet having an adhesive agent layer made from an adhesive agent composition comprising (A) a polyisobutylene resin having a mass average molecular weight of 20,000 or more, (B) a styrene copolymer and (C) an adhesiveness-imparting agent having a softening point of 135˚C or lower, wherein the component (B) comprises at least one compound selected from the group consisting of a styrene-butadiene-styrene triblock copolymer (SBS), a styrene-block-(ethylene-co-butylene)-block-styrene triblock copolymer (SEBS), a styrene-isobutylene diblock copolymer (SIB) and a styrene-isobutylene-styrene triblock copolymer (SIBS). The adhesive sheet has excellent adhesion performance, an excellent effect of preventing the invasion of water, and good transparency.

Owner:LINTEC CORP

Cement composite shape-stabilized phase change material mortar, preparation method and application thereof

ActiveCN105271991ASimple building construction methodMature building construction methodsCement compositesDry weight

Belonging to the field of building materials, the invention relates to a cement composite shape-stabilized phase change material mortar, a preparation method and application thereof. The mortar comprises a shape-stabilized phase change material with a particle size of less than 2mm, cement and sand, wherein the shape-stabilized phase change material is formed by taking a paraffin substance as the main heat storage agent, and using high density polyethylene, a styrene-butadiene-styrene triblock copolymer and expanded graphite as an encapsulation support, and the cement accounts for 20%-25% of the total dry weight, the shape-stabilized phase change material accounts for 50%-60% of the dry weight, and the water adding amount accounts for 27%-33% of the dry weight. The invention also provides a preparation method. The cement composite shape-stabilized phase change material mortar provided by the invention can be directly applied to the building wall surface, or be pasted on the building wall surface after being cast in situ into a precast slab to form a composite phase change heat storage wall so as to improve the heat storage capacity of the building envelope structure. The cement composite shape-stabilized phase change material mortar provided by the invention has the advantages of wide material sources, low cost, good storage durability, and wide application range.

Owner:BEIJING UNIV OF TECH

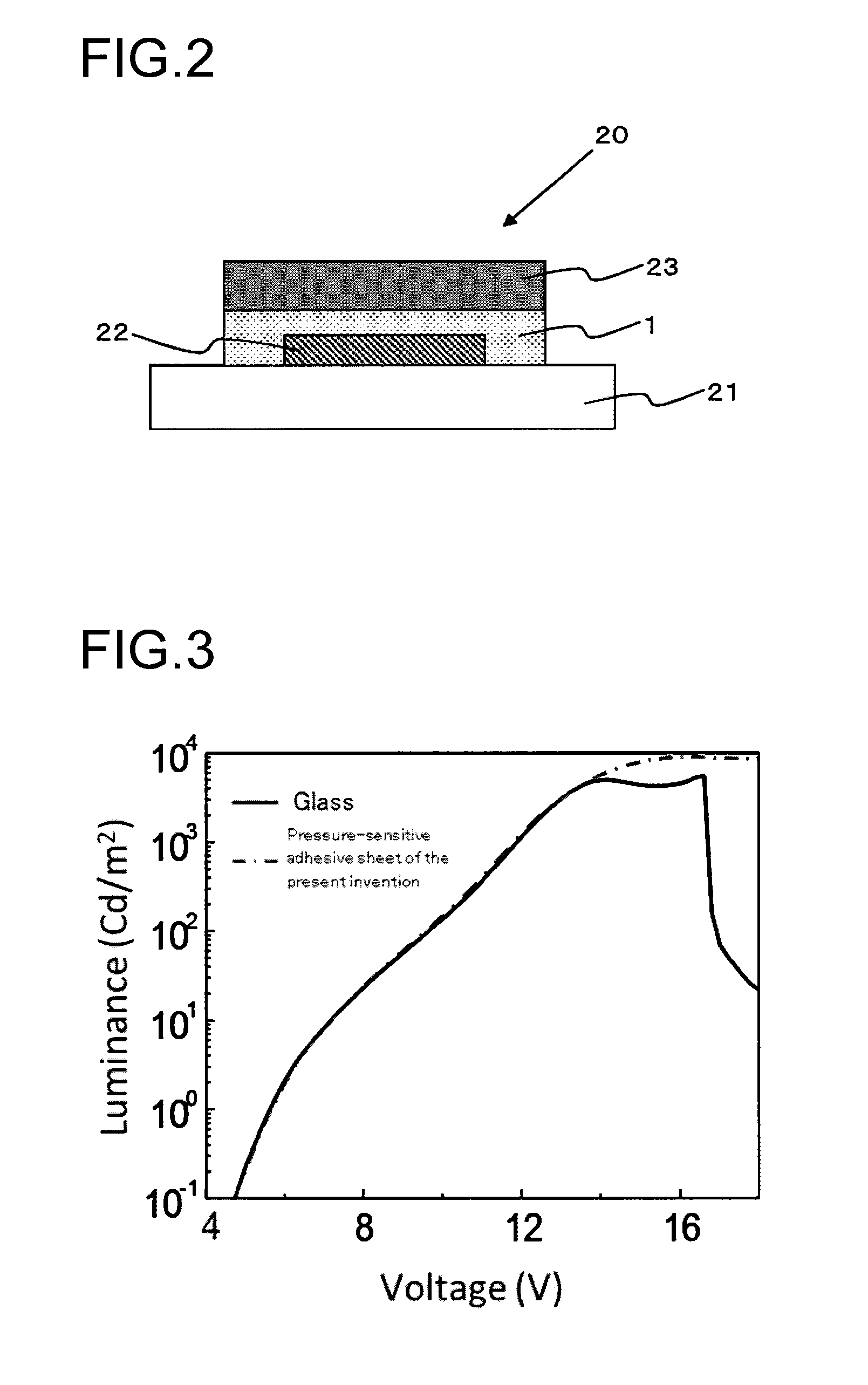

Adhesive agent composition and adhesive sheet

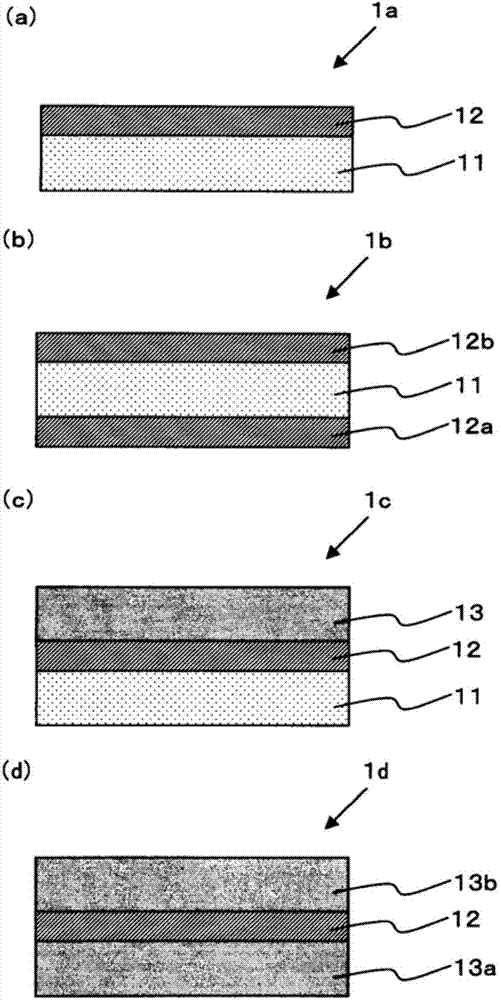

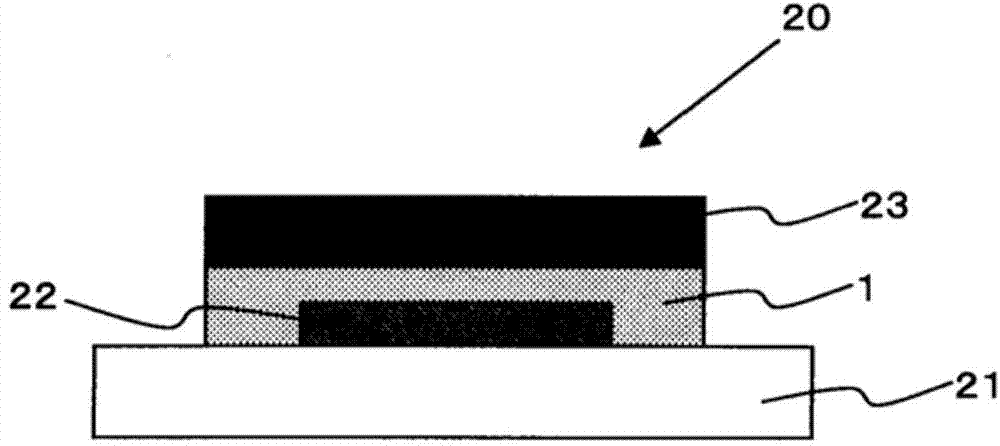

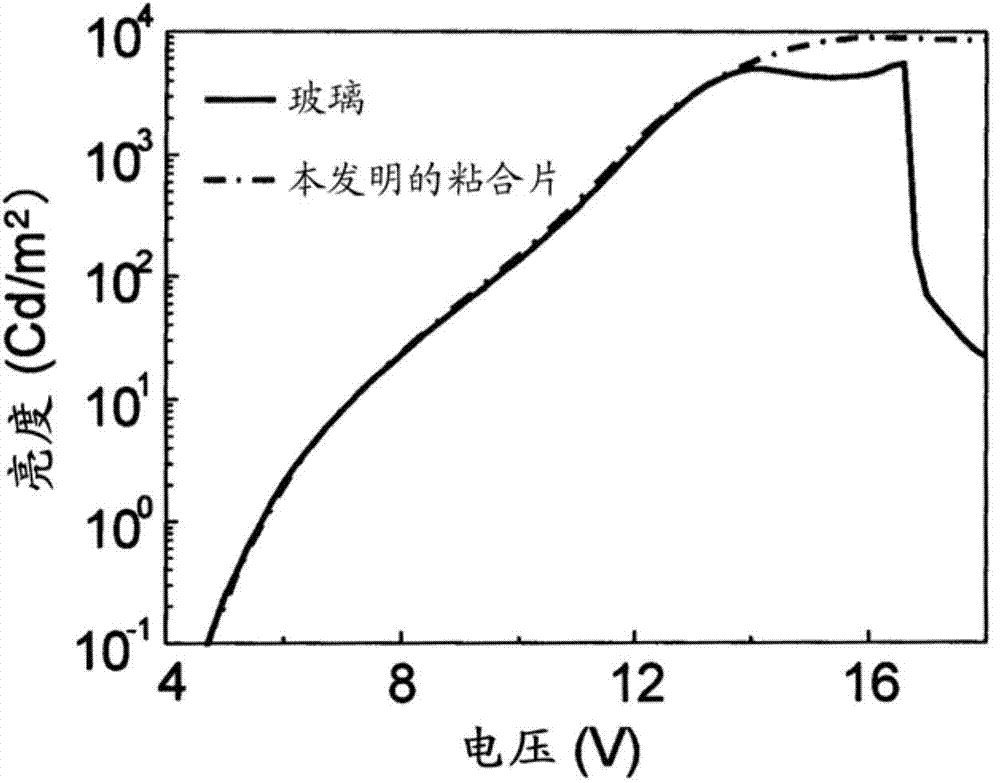

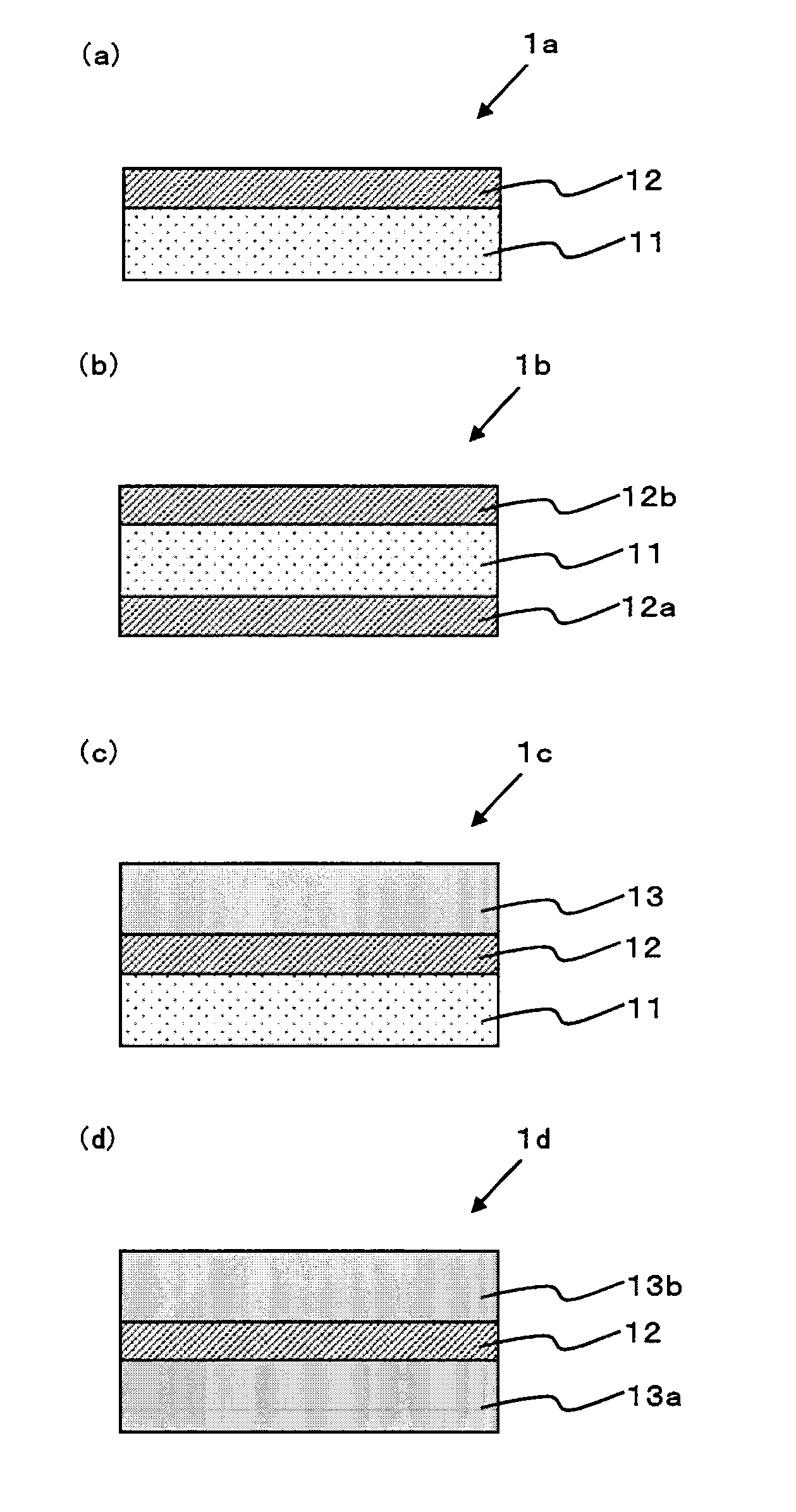

InactiveUS20150240133A1Improve adhesionEliminate the effects ofFilm/foil adhesivesElectroluminescent light sourcesPolymer scienceButadiene Dioxide

A pressure-sensitive adhesive sheet having a pressure-sensitive adhesive layer formed from a pressure-sensitive adhesive composition containing a polyisobutylene-based resin (A) having a mass-average molecular weight of 20000 or more, a styrene-based copolymer (B), and a tackifier (C) having a softening point of 135° C. or less, wherein the component (B) is one or more selected from the group consisting of a styrene-butadiene-styrene triblock copolymer (SBS), a styrene-block-(ethylene-co-butylene)-block-styrene triblock copolymer (SEBS), a styrene-isobutylene diblock copolymer (SIB), and a styrene-isobutylene-styrene triblock copolymer (SIBS), has excellent adhesive force, excels in a suppressing effect on moisture intrusion, and has good transparency.

Owner:LINTEC CORP

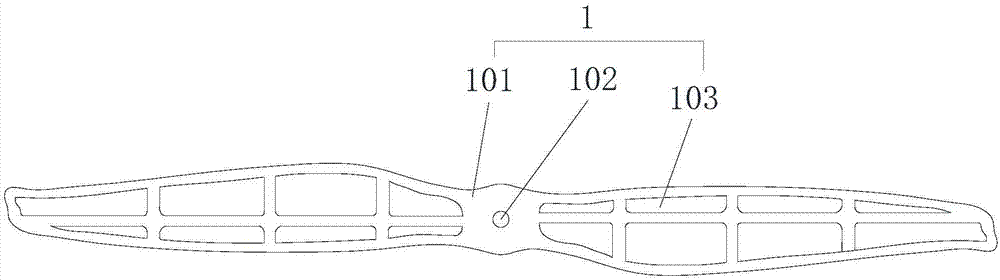

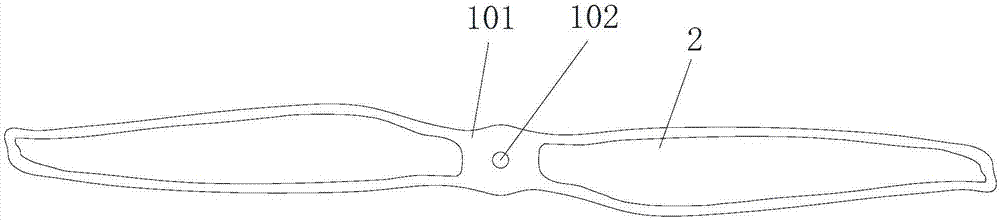

Novel compound material propeller

InactiveCN107380404AImprove mechanical propertiesGood weather resistancePropellersFiberCarbon fibers

The invention discloses a novel compound material propeller. The novel compound material propeller comprises a framework and a and covering layer, wherein the framework comprises a framework body, a mounting hole and cutouts, wherein the covering layer is adhered to the cutouts; raw materials of the framework body comprise polystyrene, polymethyl methacrylate, polystyrene, polyvinyl chloride, polyolefine, unsaturated polyester resins, styrene-butadiene-styrene triblock copolymer, ethylene-vinyl acetate copolymer, polytetrafluoroethylene resins, polyhydroxybutyrate, short-cut carbon fibers, urea-formaldehyde resins, trimethyl phosphate, zinc stearate, a dispersing agent, a silane coupling agent KH-560, and rigidity strengthening addition agents. The novel compound material propeller disclosed by the invention is high in strength, good in rigidity, light in weight, stable in structure, and excellent in weatherability, and the service life is prolonged.

Owner:安徽劲旋风航空科技有限公司

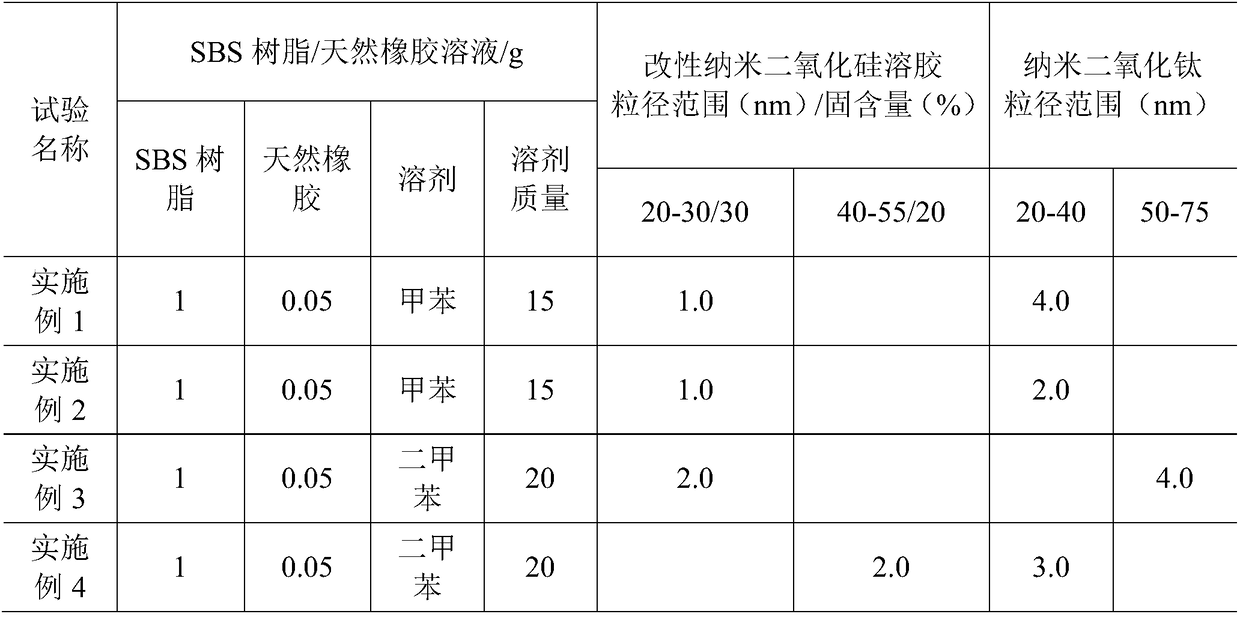

Anti-corrosion super-hydrophobic coating and preparing method and application thereof

InactiveCN109354963AImprove hydrophobicityImprove performanceAntifouling/underwater paintsNatural rubber coatingsSilanesSolvent

The invention discloses anti-corrosion super-hydrophobic coating and a preparing method and application thereof. The coating comprises, by weight, 0.8-1.2 parts of SBS resin (a styrene-butadiene-styrene triblock copolymer) produced industrially on a large scale, 0.01-0.15 part of natural rubber, 10-30 parts of a solvent, 0.1-2.0 parts of nanosilicon dioxide sol modified by a silane coupling agentand 2.0-8.0 parts of nanometer titania. The preparing method includes the steps of dissolving the SBS resin and the natural rubber in the solvent to be stirred, and adding the modified silicon dioxidesol and nanometer titanium dioxide to be stirred at a room temperature to prepare the coating. The obtained coating has the contact angle larger than 150 degrees and the rolling angle smaller than 6degrees and still has super hydrophobicity after being soaked in saline (3.5% of NaCl) for 10 days. By synergistically modifying the modified silicon dioxide sol and nanometer titanium dioxide, the multi-scale coarse structure on the surface of the plastic coating has excellent and stable hydrophobicity, has good high temperature resistance, ageing resistance and mechanical performance, and is simple in preparing method and wide in application prospect.

Owner:黄艳芬 +1

Preparation method of high temperature resistant pressure sensitive adhesive (PSA) tape for capacitor

InactiveCN102775932AMeet the production process requirementsImprove adhesionFilm/foil adhesivesGraft polymer adhesivesNitrogenDissolution

The invention discloses a preparation method of a high temperature resistant PSA tape for a capacitor. The method includes mixing a styrene-butadiene-styrene triblock copolymer with a reaction solvent with stirring, heating up for dissolution, adding active monomers and initiators in batches under the protection of nitrogen, reacting for a moment and adding tackifying resin and curing agents, reacting for a moment and cooling to obtain the PSA, coating the PSA on a base material, coating a separant on the back side of the base material, and drying to obtain the PSA tape. According to the preparation method, the production cost is reduced, the melting temperature of the PSA is improved to above 170 DEG C from below 100 DEG C when the PSA is unmodified, the obtained high temperature resistant PSA tape has firm adhesion without falling off or displacement, leads have no adhesive residue, the problem that a core is bonded and difficult to pull during a board removal is solved, and production technology requirements for capacitors are satisfied.

Owner:昆山旭虹精密零组件有限公司

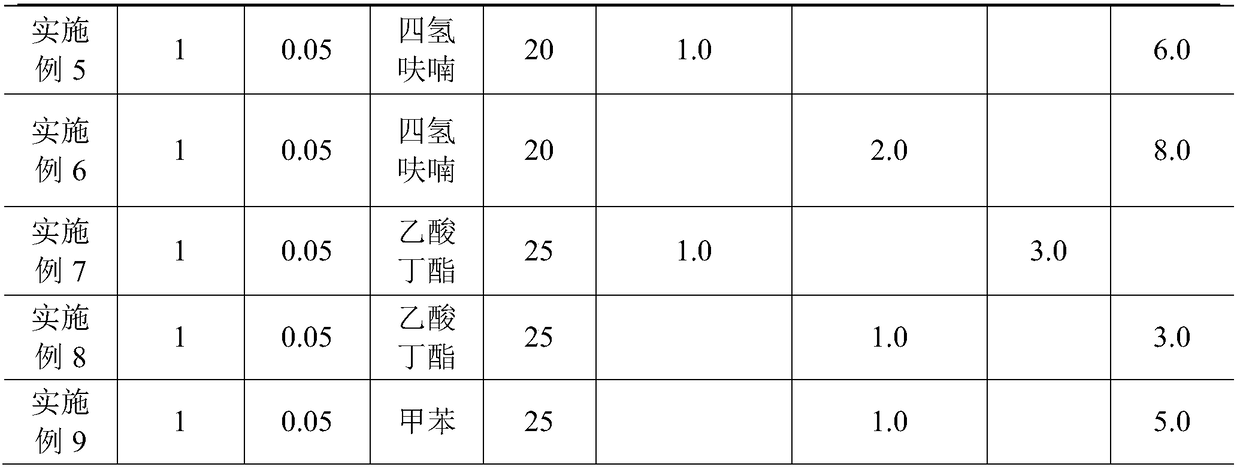

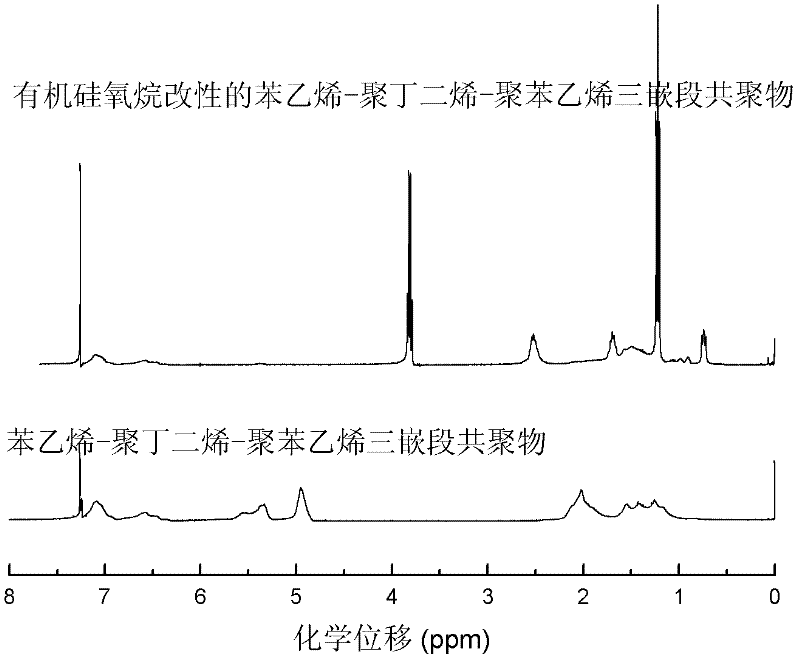

A kind of method for preparing mesoporous silica

InactiveCN102295291ALow reaction temperatureEasy to manufactureSilicaMesoporous silicaSilicon dioxide

The invention relates to a method for preparing mesoporous silicon dioxide, the method is characterized in that mercapto-vinyl can be used for a free radical addition reaction, organo-silicone containing a mercapto group and polybutadiene block of triblock copolymer of styrene-butadiene-styrene are reacted, an organo-siloxane modified styrene-butadiene-styrene triblock copolymer can be obtained, then the organo-siloxane modified styrene-butadiene-styrene triblock copolymer is carried out a sol-gel reaction with a silicon source under the acidic or alkaline condition to form gel, the mesoporous silicon dioxide is obtained after cracking the gel. Compared with the prior art, the mesoporous silicon dioxide material has the average pore diameter of 5-18nm, the pore volume of 0.24-0.30 cm<3> / g, the specific surface area of 418-480 cm<2> / g, and has the advantages of cheap raw material and easy raw material acquisition, mild reaction condition, simple and high efficient preparation process, safety and environmental protection, and is convenient for large scale production.

Owner:SHANGHAI JIAO TONG UNIV

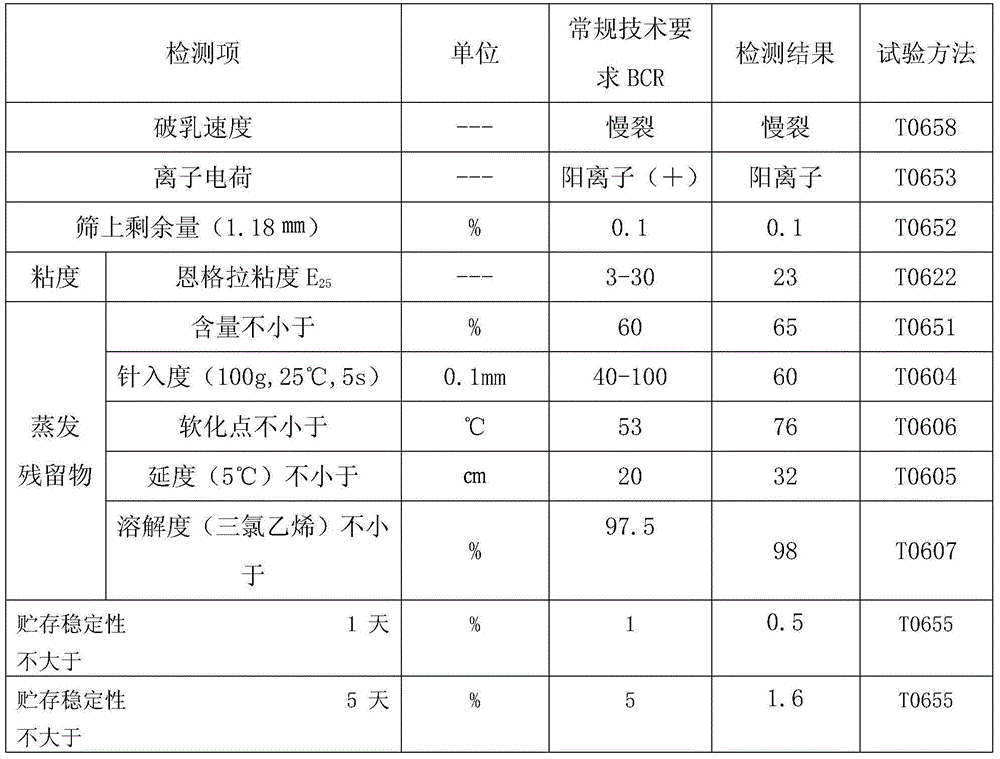

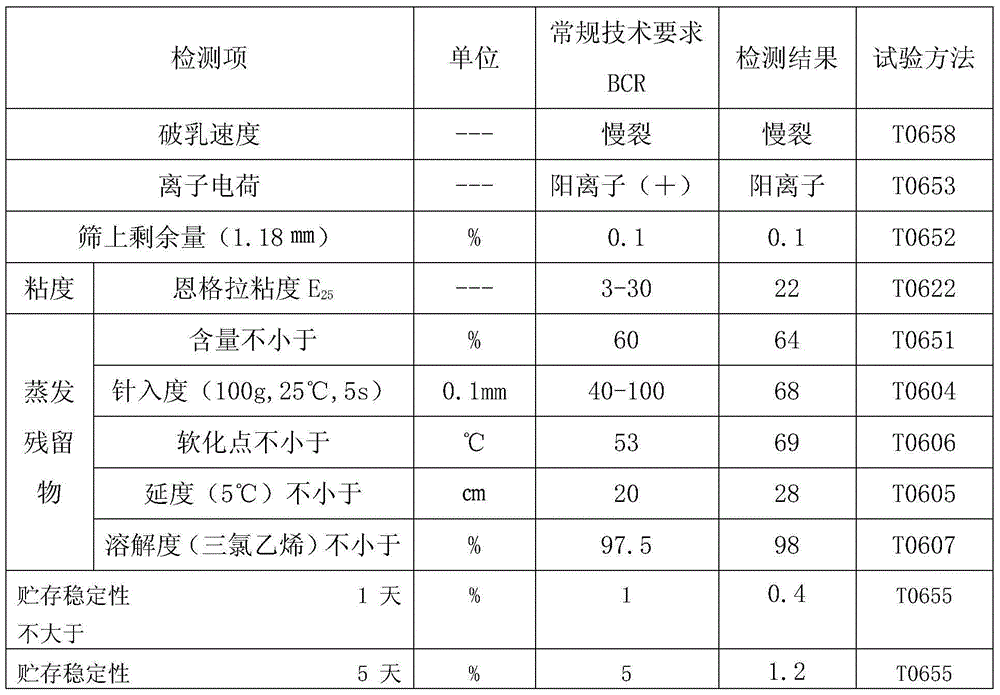

SBS (styrene-butadiene-styrene triblock copolymer) and liquid rubber composite modified emulsified asphalt and preparation method thereof

ActiveCN104479375AFix compatibility issuesSolve the real problemPlastic recyclingBuilding insulationsPolymer scienceStyrene-butadiene-styrene triblock copolymer

The invention provides SBS (styrene-butadiene-styrene triblock copolymer) and liquid rubber composite modified emulsified asphalt and a preparation method thereof. The composite modified emulsified asphalt is prepared from the following components in parts by weight: 45-75 parts of SBS and pasty liquid rubber composite modified asphalt, 22-45 parts of water, 0.01-1.6 parts of a crosslinking agent, 2.5-13 parts of a cationic asphalt emulsifying agent, 0.5-3.0 parts of a stabilizing agent and 0.1-2.5 parts of a pH value regulator. By adopting the SBS and liquid rubber composite modified emulsified asphalt provided by the invention, the technical problem that rubber powder modified asphalt is difficult to emulsify can be solved, prepared liquid rubber can be subjected to emulsification more easily, and composite SBS is added to ensure that the pavement performance of the composite modified emulsified asphalt can be greatly improved, and wider application ranges in road maintenance and engineering construction of roads under construction can be achieved. In addition, by applying the pasty liquid rubber, good economical performance can be achieved, and waste tires can also be effectively used.

Owner:TIANJIN HI TECH ENVIRONMENT DEV CO LTD

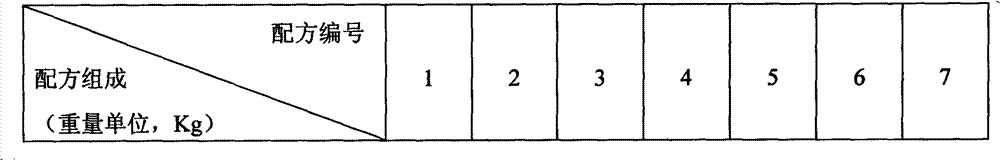

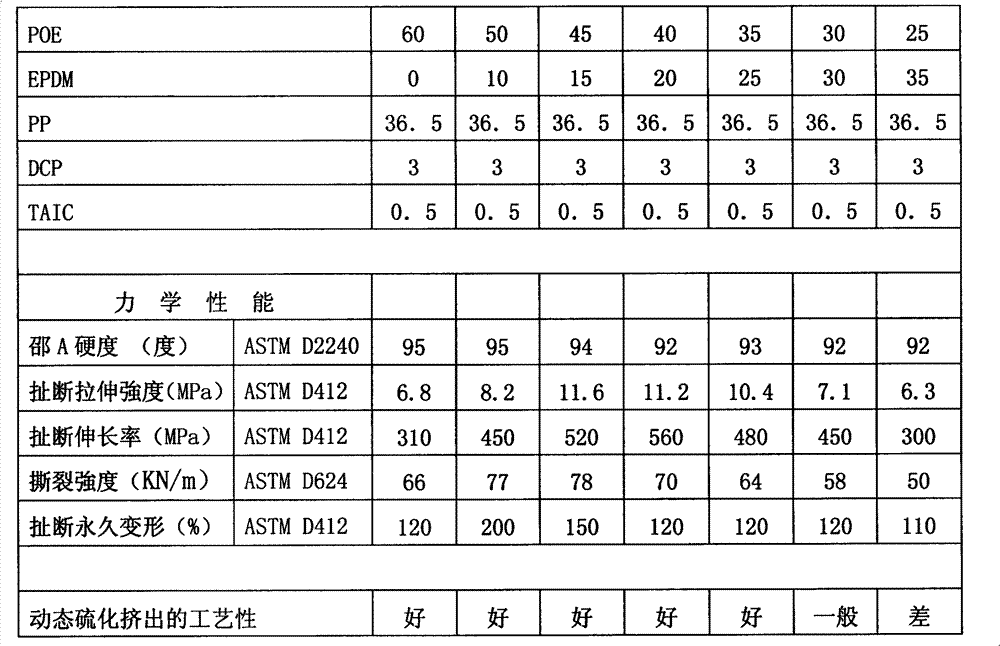

Flexible pipe material for temperature resistant and thermoplastic elastomer and preparation method thereof

InactiveCN102786763AStrong aging and weather resistanceGood mechanical propertiesFlexible pipesElastomerRubber material

The present invention discloses a flexible pipe material for a temperature resistant and thermoplastic elastomer and a preparation method thereof. The material is composed of the following components, by weight percentage: 25-45% of a styrene-butadiene-styrene triblock copolymer, 20-40% of a dynamic vulcanization master batch, 20-40% of a plasticizer, and 15-25% of a filling material. The dynamic vulcanization master batch is composed of the following components, by weight percentage: 35-50% of a polyolefin elastomer, 15-30% of a rubber material, 25-45% of a thermoplastic resin, 1-4% of a crosslinking agent, and 0.2-0.6% of an auxiliary crosslinking agent. The invention also discloses a preparation method of the flexible pipe material for the temperature resistant and thermoplastic elastomer. According to the invention, the polyolefin elastomer is combined with the rubber material, and a chemical crosslinking structure is introduced through dynamic vulcanization, so as to reinforce the styrene-butadiene-styrene triblock copolymer material; and high temperature and hot water resistance of the styrene-butadiene-styrene triblock copolymer material is greatly improved, so as to avoid deformation leakage and rupture for long-time cycle working.

Owner:SHANGHAI RIJIE ELASTOMER PLASTIC

High modulus modified asphalt and preparation method

ActiveCN103102708AReduce manufacturing costReduce the amount addedBuilding insulationsPolymer scienceStyrene-butadiene-styrene triblock copolymer

The invention belongs to the modified asphalt technical field, and particularly relates to a high modulus modified asphalt and a preparation method. The high modulus modified asphalt comprises the following raw materials by weight: 90-95% of asphalt, 4-4.5 parts of styrene-pyrrolylene-styrene triblock copolymer and 3-3.5 parts of high modulus asphalt modifier. The high modulus modified asphalt has the advantages of low preparation method, high temperature resistance and strong deformation resistance, and the preparation method is simple and easy to be carried out, and the preparation cost is low.

Owner:GUANGDONG SILVER AGE SCI & TECH CO LTD

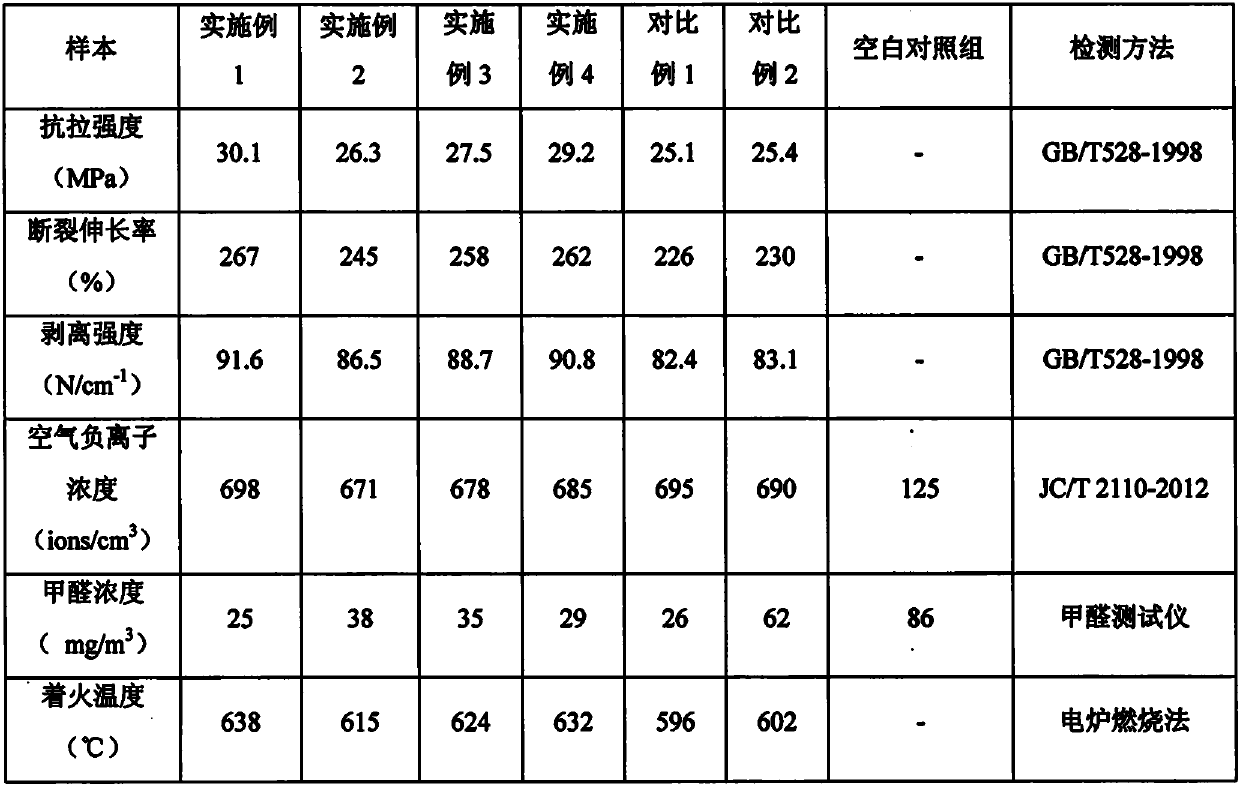

Inorganic fireproof decoration material capable of releasing negative oxygen ions, and preparation method thereof

ActiveCN110105827AHigh mechanical strengthGood negative oxygen ion release abilityFireproof paintsAnti-corrosive paintsRare earthOxygen ions

The invention discloses an inorganic fireproof decoration material capable of releasing negative oxygen ions, and a preparation method thereof. The material is prepared from, by weight, 30-50 parts ofa silicon-acrylic emulsion, 10-25 parts of heavy calcium carbonate-supported graphene oxide, 10-20 parts of tourmaline powder-supported carbon nanotubes, 12-25 parts of titanium dioxide, 10-15 partsof rare earth, 8-16 parts of potassium titanate whiskers, 3-8 parts of magnesium hydroxide, 5-10 parts of perlite micro-powder, 6-10 parts of antimony trioxide, 4-9 parts of a titanate coupling agent,3-6 parts of a functional assistant and 15-30 parts of water, wherein a mixture of the magnesium hydroxide, perlite micro-powder and antimony trioxide is modified with a maleic anhydride-grafted hydrogenated styrene-butadiene-styrene triblock copolymer. The decoration material prepared in the invention has the advantages of high mechanical strength, good air purification effect and excellent flame retardant performance, so the material has a broad application prospect in the field of decoration materials.

Owner:常州巢典建筑科技有限公司

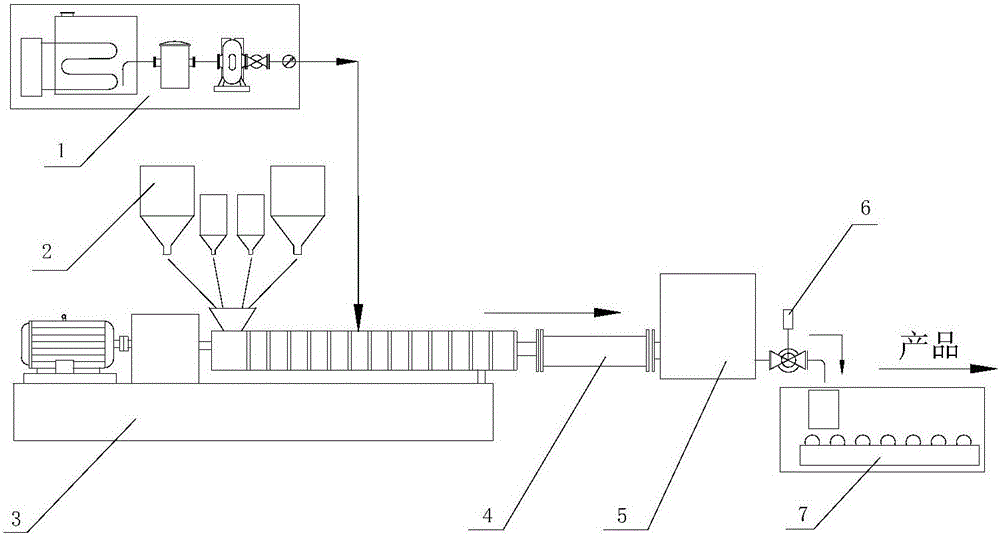

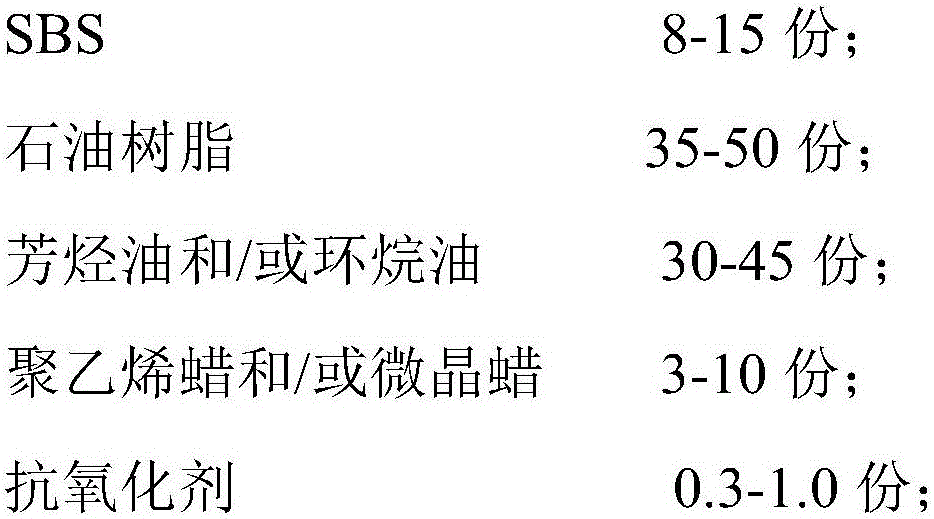

Color bituminous cement in bags or barrels and production device and method thereof

The invention provides color bituminous cement in bags or barrels and production device and method thereof. The bituminous cement contains the following components in parts by weight: 8-15 parts of SBS, 35-50 parts of petroleum resin, 30-45 parts of aromatic oil and / or naphthenic oil, 3-10 parts of polyethylene wax and / or microcrystalline wax and 0.3-1.0 part of antioxidant, wherein the SBS is linear and / or star styrene-butadiene-styrene block copolymer, the block ratio of styrene to butadiene is 30 / 70, and the molecular weight is 100000-200000. The color bituminous cement provided by the invention has the advantages of easily available raw materials for production, convenient operation of production device, safety and reliability of products, superior performance, high percent of pass, stable product quality and performance, conveniently adjustable product variety and strong adaptability.

Owner:上海砼仁环保技术发展有限公司

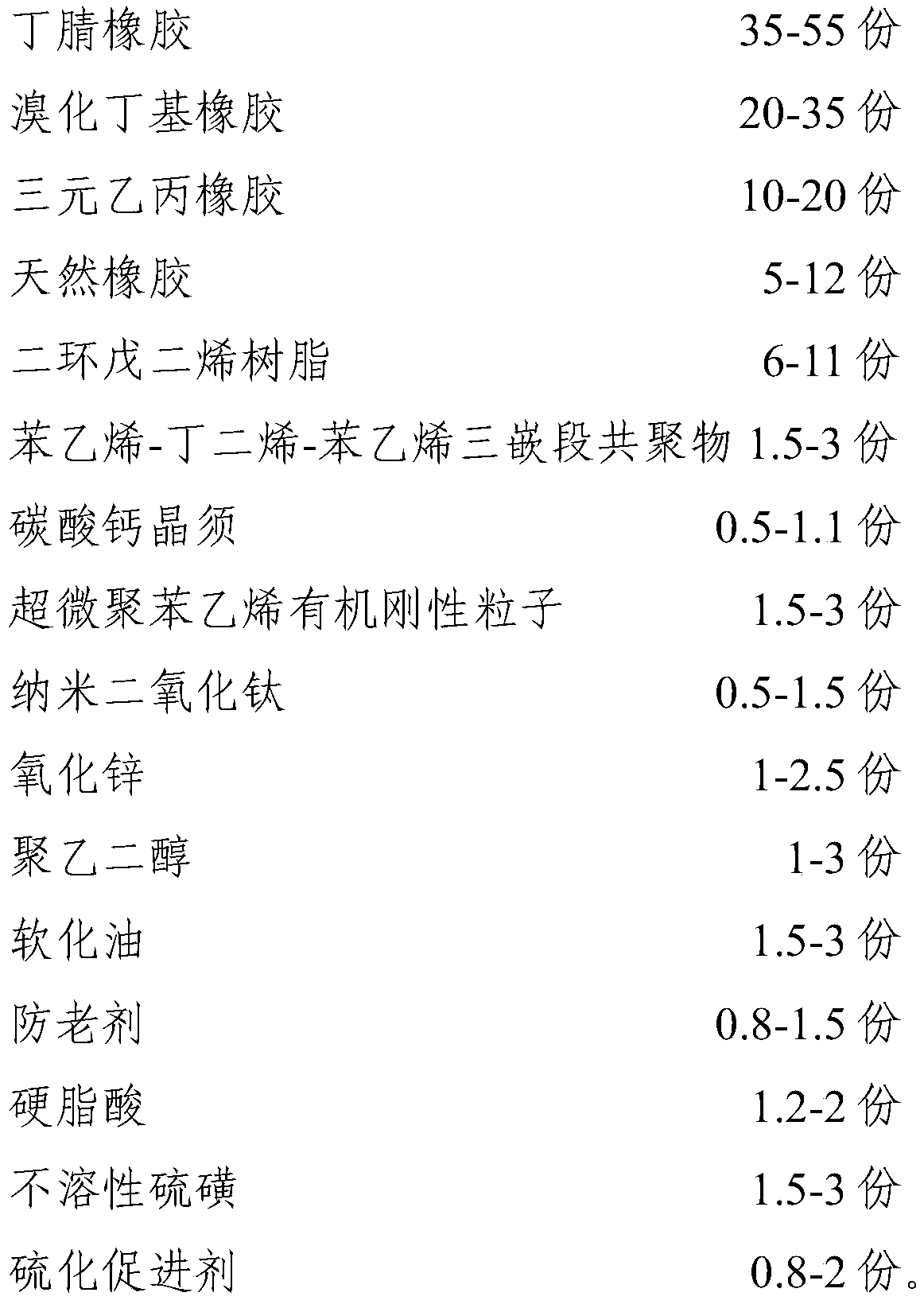

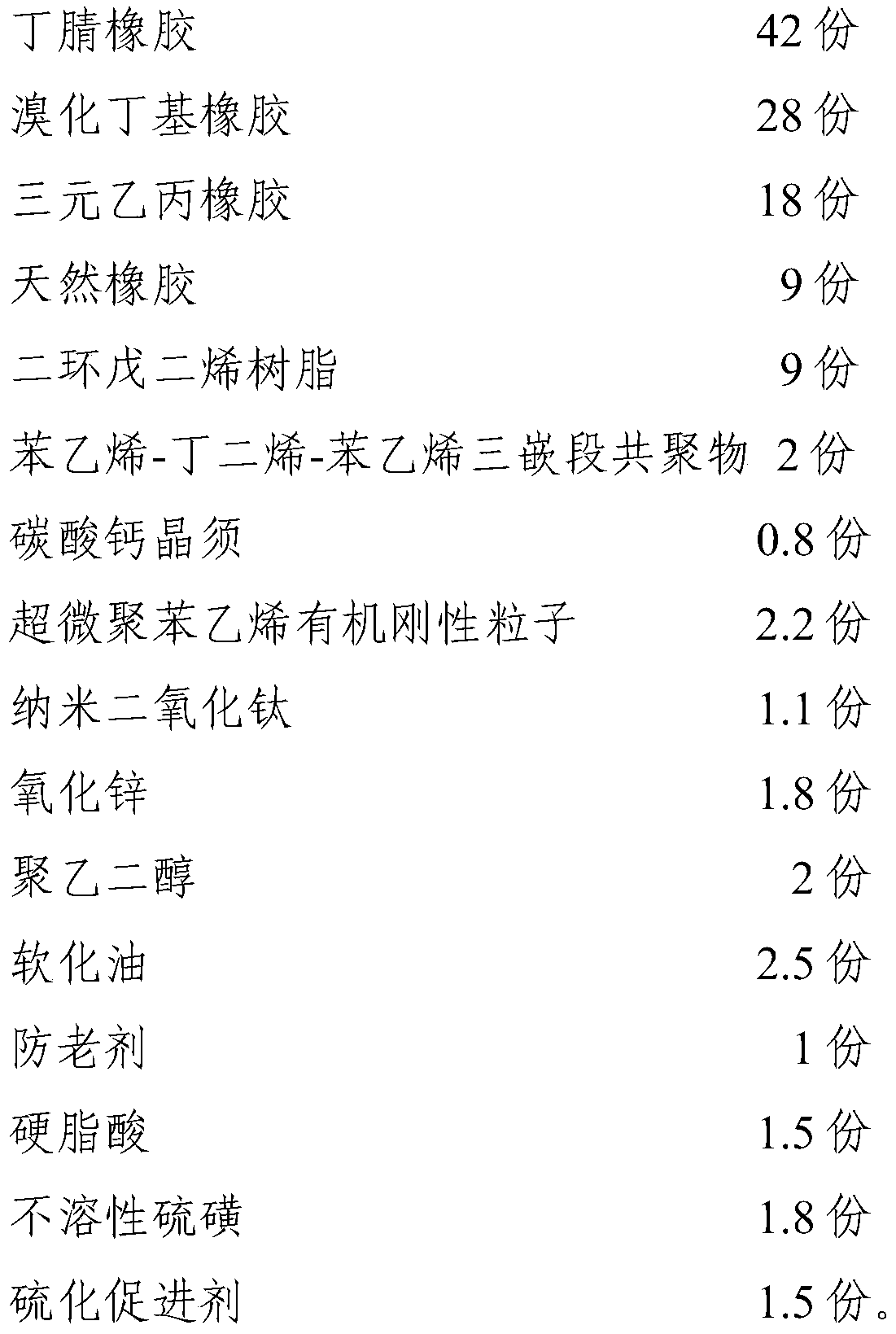

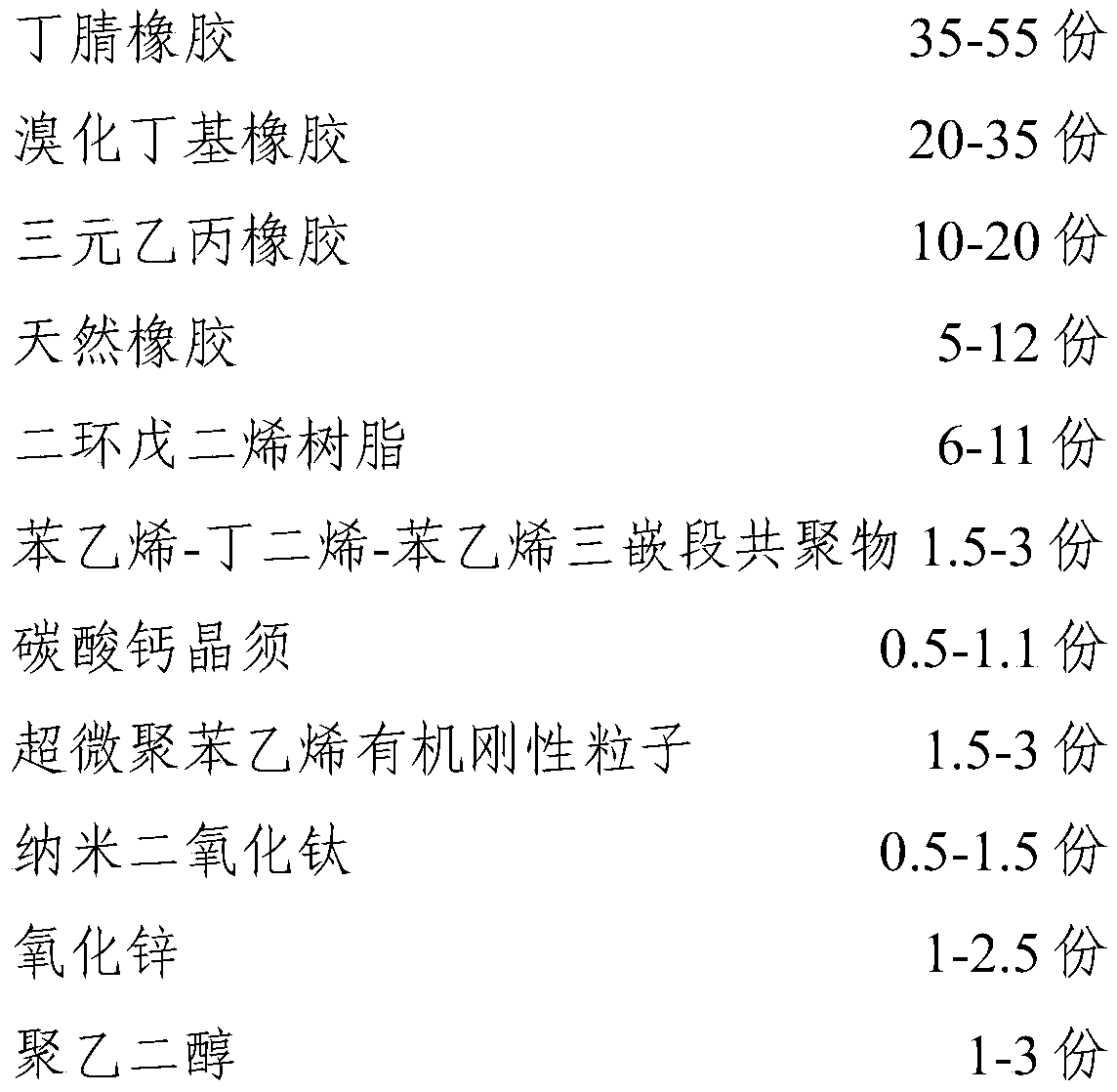

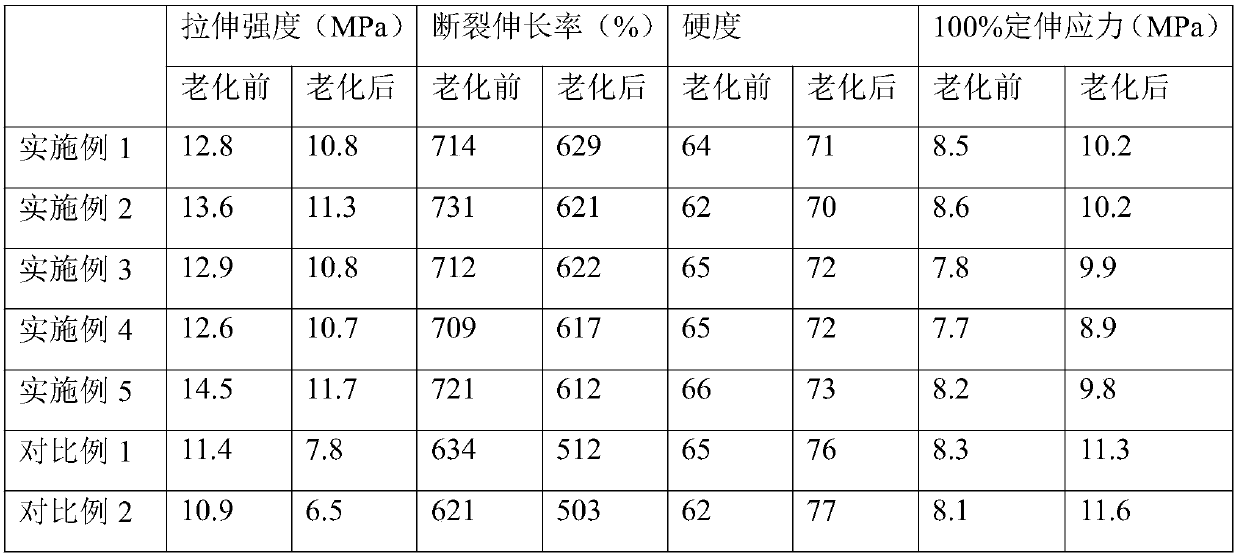

Antiskid wear-resistant rubber sole and preparation method thereof

InactiveCN111073072AExcellent ozone resistanceIncrease elasticitySolesRubber materialPolymer science

The invention provides an antiskid wear-resistant rubber sole and a preparation method thereof, and relates to the technical field of sole materials. The antiskid wear-resistant rubber shoe sole comprises the following raw materials: nitrile rubber, brominated butyl rubber, ethylene propylene diene monomer, natural rubber, dicyclopentadiene resin, a styrene-butadiene-styrene triblock copolymer, calcium carbonate whiskers, ultramicro polystyrene organic rigid particles, nano titanium dioxide, zinc oxide, polyethylene glycol, softening oil, an anti-aging agent, stearic acid, insoluble sulfur anda vulcanization accelerator. The nitrile rubber is used as a main rubber material, the brominated butyl rubber, the ethylene propylene diene monomer and the natural rubber are added for matching, andthe dicyclopentadiene resin, the styrene-butadiene-styrene triblock copolymer, the calcium carbonate whiskers and the ultramicro polystyrene organic rigid particles are added so that the prepared rubber sole has better skid resistance and wear resistance and is good in toughness, high in strength, good in aging resistance and excellent in comprehensive performance.

Owner:安徽铭捷讯网络科技有限公司

Modified bamboo fiber reinforced anti-aging styrene-butadiene rubber and preparation method thereof

The invention provides a preparation method of modified bamboo fiber reinforced anti-aging styrene-butadiene rubber. The preparation method comprises the following steps that firstly styrene-butadienerubber and a modified polarized styrene-butadiene-styrene triblock copolymer are subjected to mixing, the mixing temperature is 80-95 DEG C, and the time is 2-5 min; then carbon black, zinc oxide, stearic acid, modified bamboo fibers and gamma-glycidoxypropyltrimethoxysilane modified zinc oxide are added sequentially; and finally, an accelerant D, an accelerant TMTD, an anti-aging agent 4020 andsulfur are added, then mill run and triangle packaging are performed, piece discharging is performed after mixing for 4-8min, and rubber materials are stored for 24h and then vulcanized. The modifiedbamboo fiber reinforced anti-aging styrene-butadiene rubber has good aging resistant performance and excellent mechanical properties.

Owner:陶伟珍

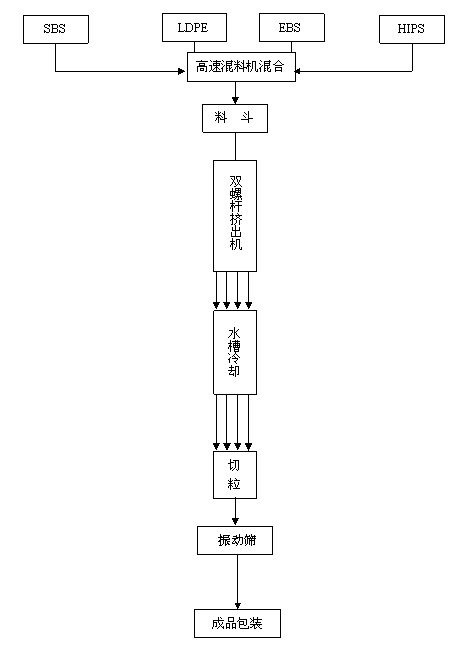

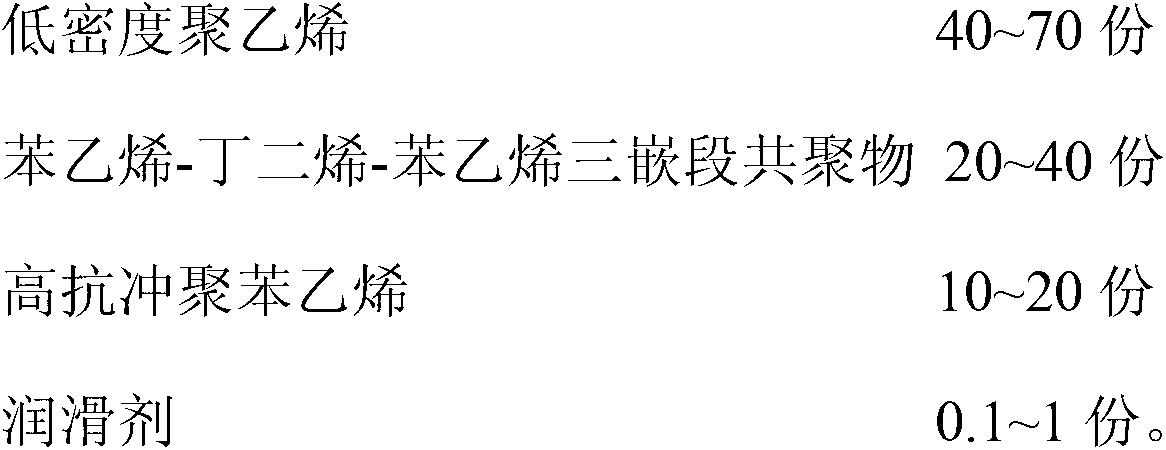

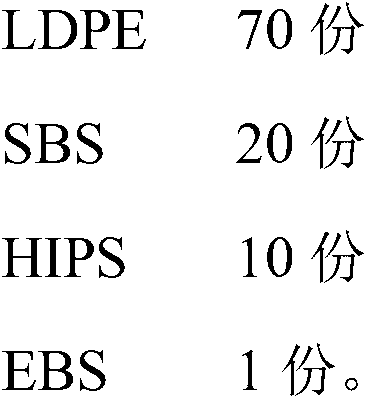

High-pressure-tolerant slow-leakage-rate gasket material for beer bottle cap and preparation method of material

InactiveCN103012903AImprove pressure resistanceLow Chronic Leak RateLow-density polyethyleneEngineering

Owner:JIANGSU TOP POLYMER ENTERPRISE

Preparation method of modified granite aggregate, and adhesion testing method

InactiveCN108863132AImprove adhesion levelEasy to use in engineeringFlow propertiesWater bathsRoad surface

The invention discloses a preparation method of modified granite aggregate, and an adhesion testing method. The preparation method comprises the following process steps: heating styrene-butadiene-styrene triblock copolymer (SBS) modified asphalt, then adding a liquid anti-stripping agent into the heated SBS modified asphalt, stirring evenly, and placing the obtained mixture in an environment of 175-180 DEG C to prepare a mixed solution a; weighing granite aggregate and cement, and heating up to 175-181 DEG C; then, uniformly stirring the heated granite aggregate and cement, and carrying out heat preservation at 175-180 DEG C to obtain a mixture b; blending the mixed solution a in a mixing container, adding the mixture b during blending, and uniformly stirring to obtain the modified graniteaggregate. The modified granite aggregate is placed in a constant temperature water bath at 76-84 DEG C, part of the aggregate is taken out and put into cold water at set intervals, and the aggregateis completely taken away in 4-6 times; finally, the adhesion grade is evaluated according to the percentage of a stripping area. The modified granite aggregate prepared by the method is strong in adhesion durability and good in water stability, and achieves the level-5 adhesion requirement of the asphalt pavement. The invention also discloses an adhesion evaluation method which is convenient to apply and has a good correlation with engineering.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

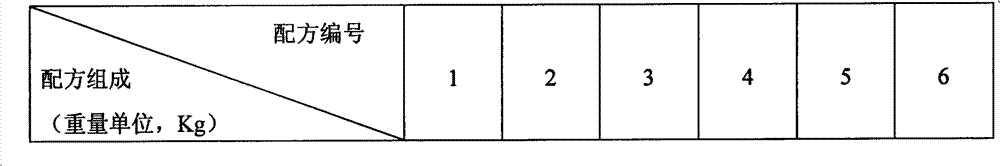

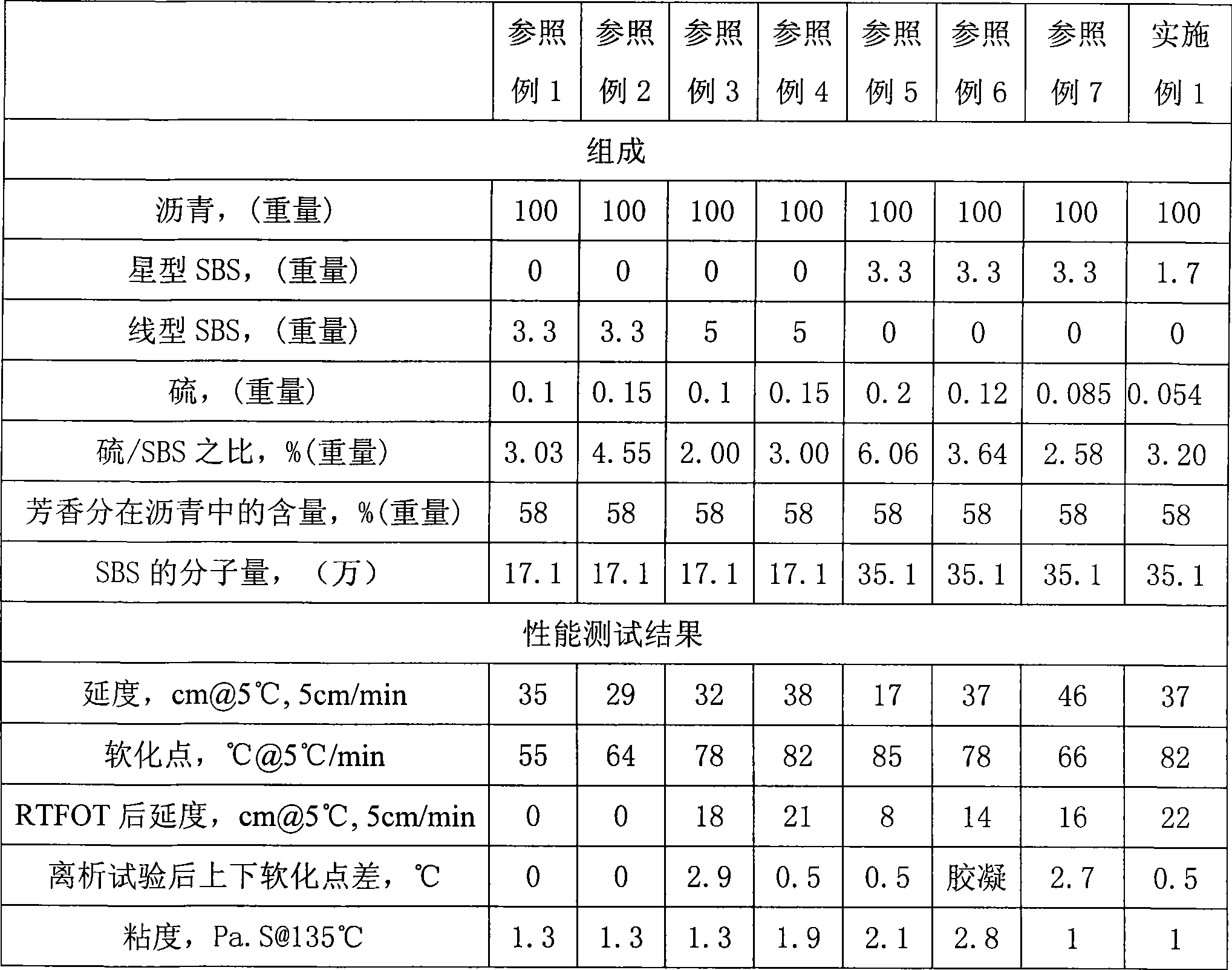

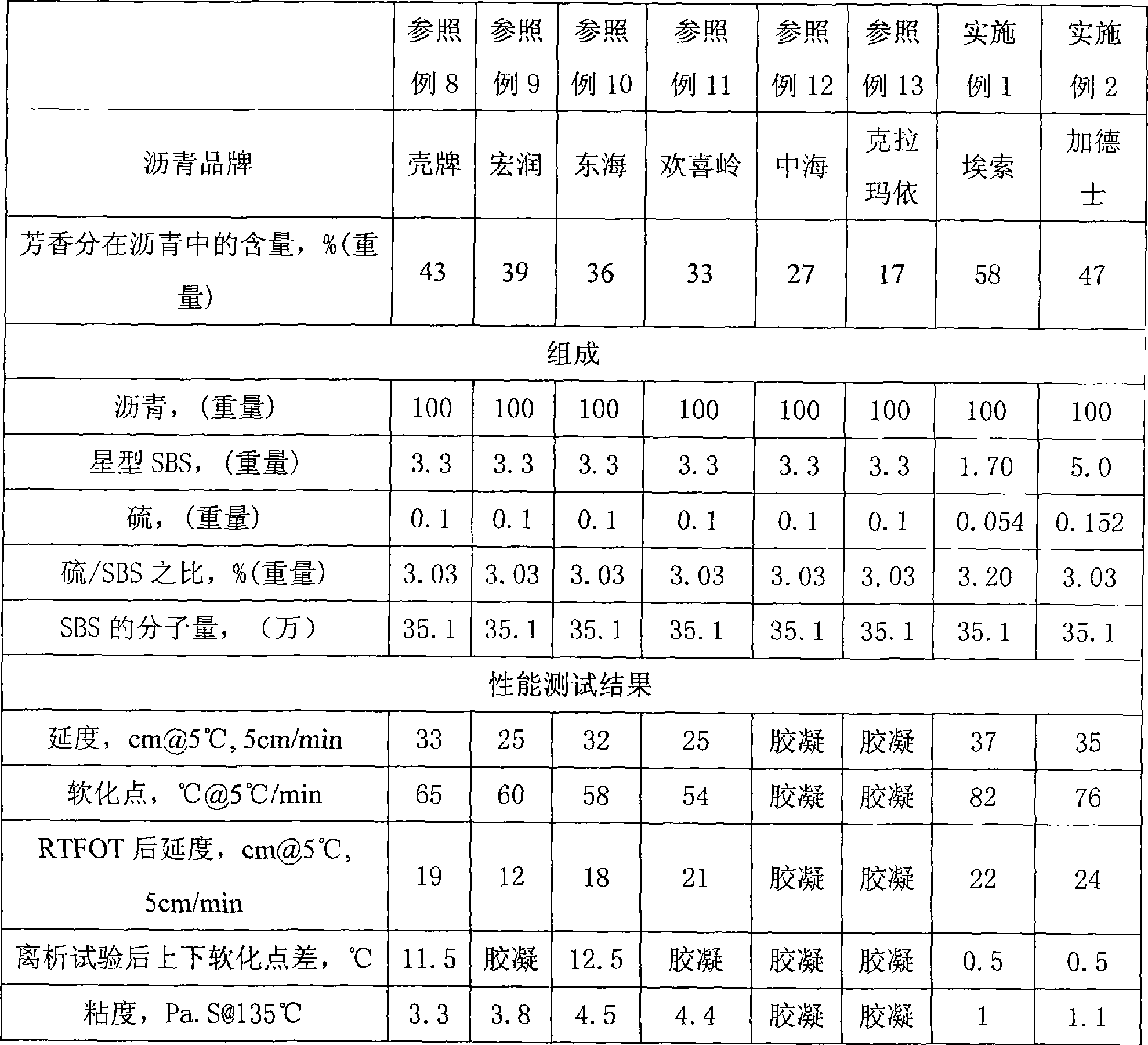

Method for preparing modified asphalt

InactiveCN101445662AHigh softening pointHigh ductility after agingBuilding insulationsPolymer scienceSulfur

Owner:TONGJI UNIV

Beta-cyclodextrin/styrene-butadiene-styrene triblock copolymer modified asphalt and preparation method thereof

InactiveCN112724696AEvenly dispersedUniform and effective dispersionBuilding insulationsPolymer scienceButadiene Dioxide

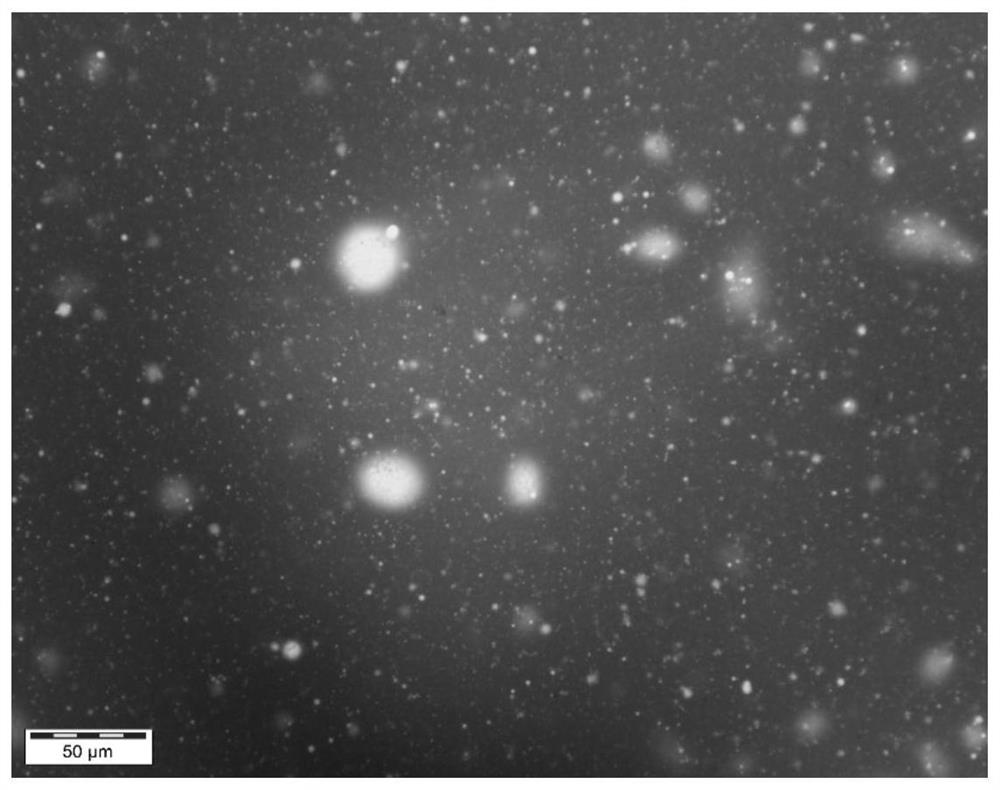

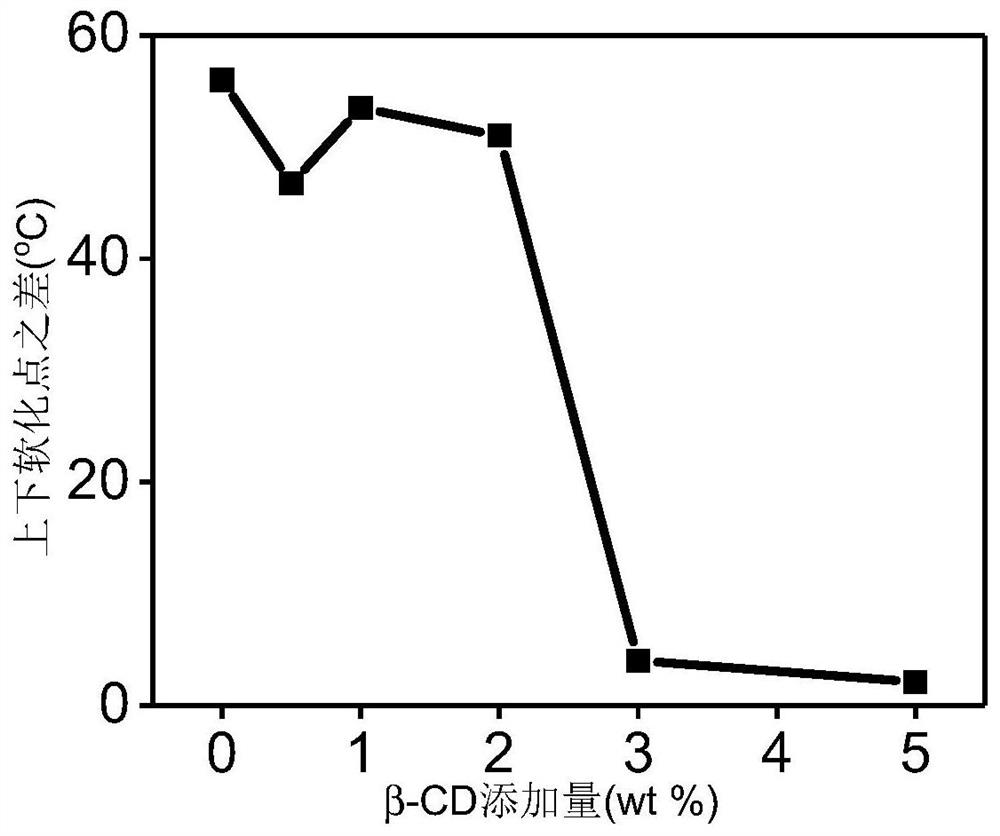

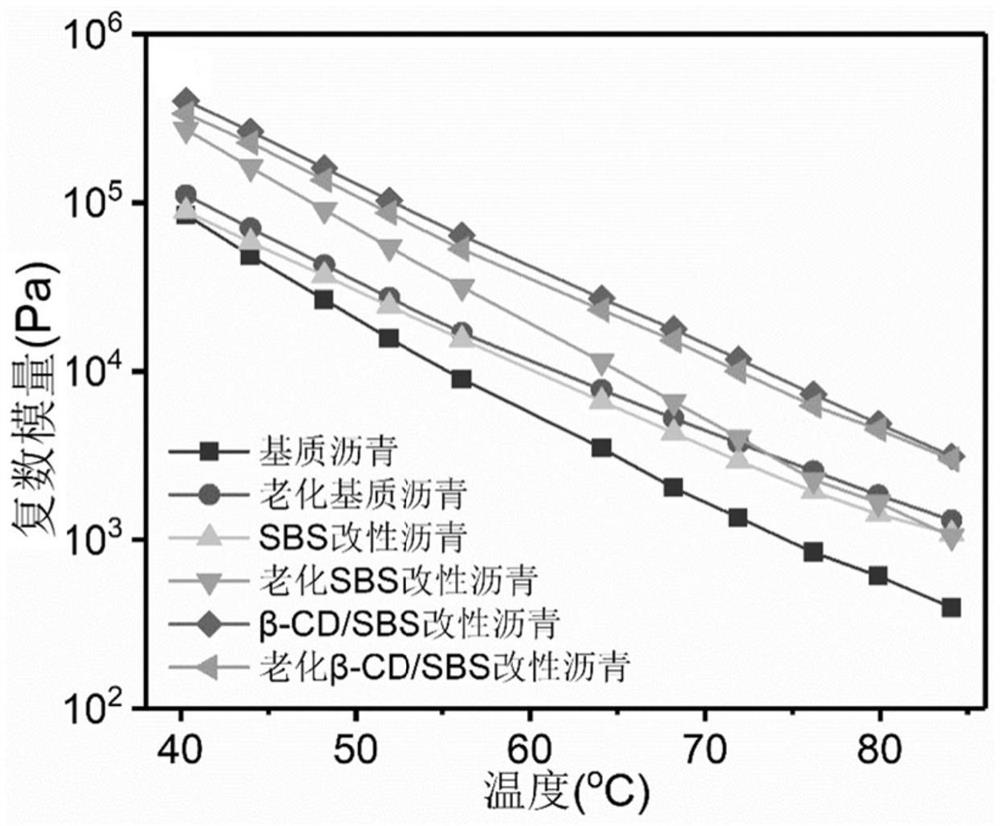

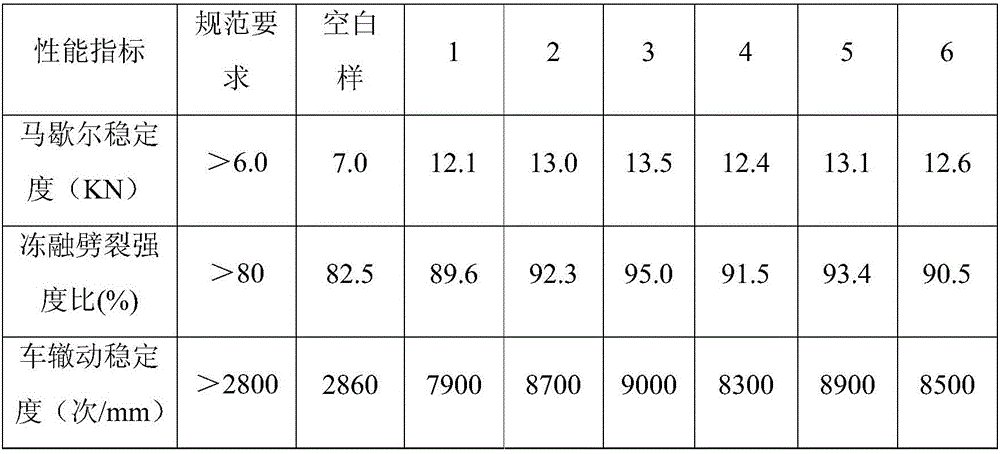

The invention discloses beta-cyclodextrin / styrene-butadiene-styrene triblock copolymer modified asphalt and a preparation method thereof, and belongs to the technical field of building materials. The preparation method comprises the following steps: uniformly dispersing a beta-cyclodextrin solution into styrene-butadiene-styrene triblock copolymer modified asphalt to obtain a mixture, and carrying out shearing treatment and development treatment on the obtained mixture to obtain the beta-cyclodextrin / styrene-butadiene-styrene triblock copolymer modified asphalt. The preparation method disclosed by the invention can be used for processing on the basis of an original processing technology, is safe to operate and is suitable for expanded production and popularization. By combining the performance advantages of the styrene-butadiene-styrene triblock copolymer and the beta -cyclodextrin, the prepared beta -cyclodextrin / styrene-butadiene-styrene triblock copolymer modified asphalt has the characteristics of better high-temperature stability and low-temperature cracking resistance, excellent storage stability and outstanding thermo-oxidative aging resistance.

Owner:XIAN UNIV OF TECH

Premix and copolymerization type asphalt mixture compound modifier and preparation method thereof

InactiveCN106280504AIncrease temperatureImproved resistance to fatigue crackingBuilding insulationsGlycidyl methacrylatePolymer modified

The invention relates to a premix and copolymerization type asphalt mixture compound modifier. The compound modifier is prepared from, by weight, 50-70% of modified polyethylene particles, 20-30% of activated modified waste rubber powder and 10-20% of SBS asphalt modifier. The modified polyethylene particles are prepared by evenly mixing polyethylene particles and glycidyl methacrylate according to the mass ratio of 100:5 and conducting mechanical stirring reaction for 1 h at 90-100 DEG C; the activated modified waste rubber powder is prepared by mixing waste rubber powder and naphthenic rubber oil according to the mass ratio of 100:5 and conducting mechanical stirring for 50-60 min at 90-100 DEG C; the SBS asphalt modifier is a styrene-butadiene-styrene triblock copolymer. The problem that a simple polymer is simplex in modification effect is solved, all performance of the asphalt is comprehensively improved, and meanwhile the polymer modification cost is reduced.

Owner:WUHAN UNIV OF TECH

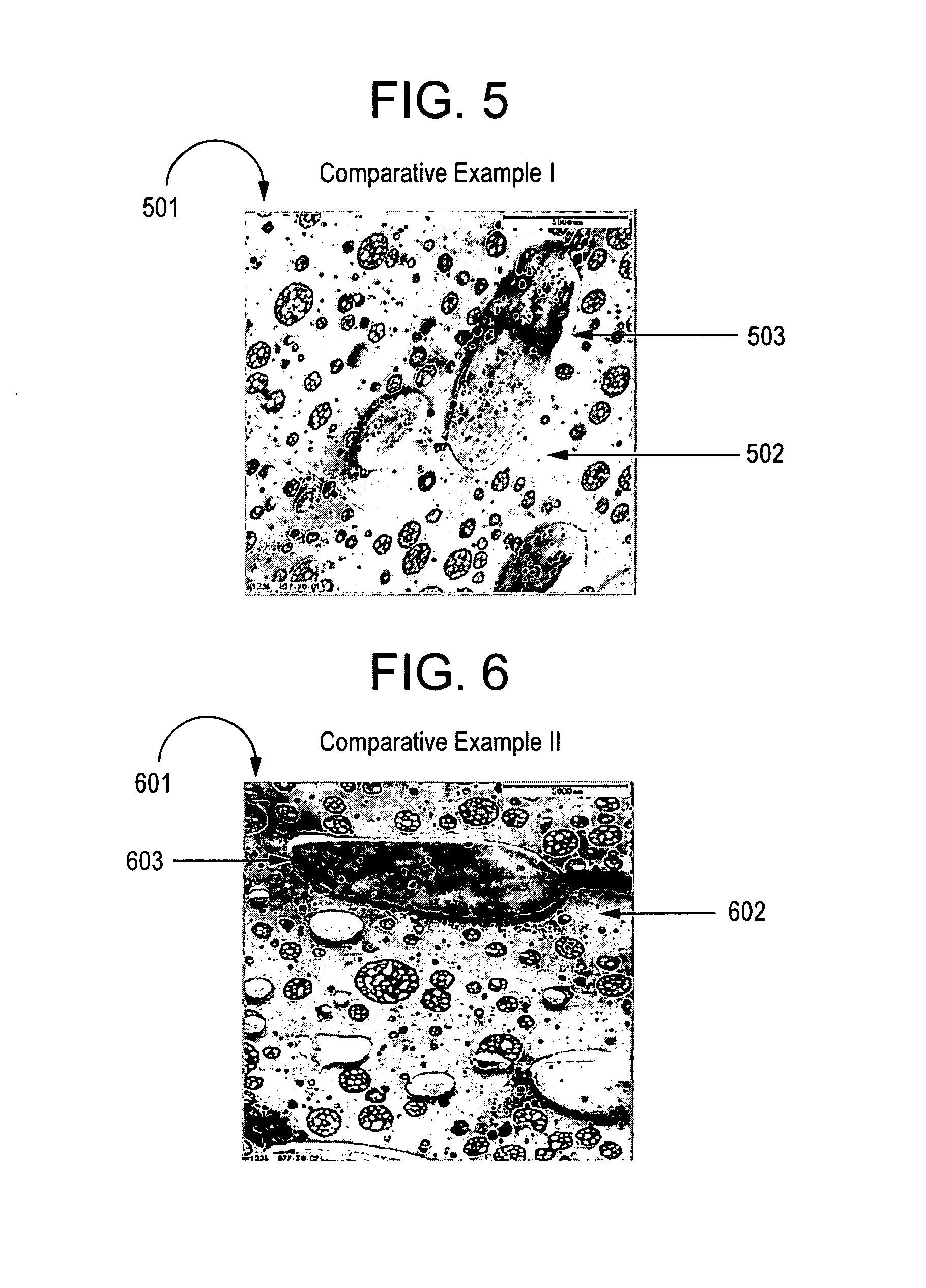

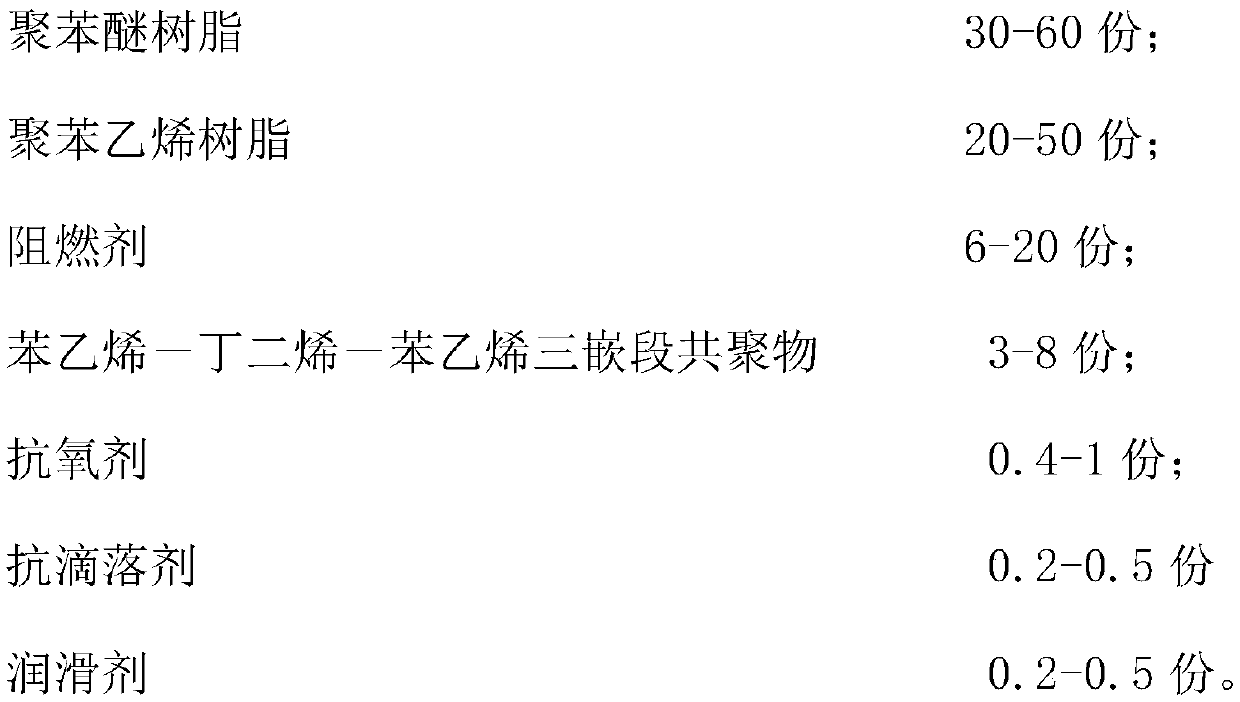

Polystyrene blends and a method of making same

Disclosed are blends of polystyrene and at least one of syndiotactic polypropylene, ethylene propylene copolymers, and styrene-butadiene-styrene triblock copolymers. These blends are prepared using solution polymerization and have unique morphologies and desirable physical properties. The blends can also be prepared with graft-promoting or crosslinking agents and rubbers to prepare modified high impact polystyrene.

Owner:FINA TECH

Polystyrene blends and a method of making same

Disclosed are blends of polystyrene and at least one of syndiotactic polypropylene, ethylene propylene copolymers, and styrene-butadiene-styrene triblock copolymers. These blends are prepared using solution polymerization and have unique morphologies and desirable physical properties. The blends can also be prepared with graft-promoting or crosslinking agents and rubbers to prepare modified high impact polystyrene.

Owner:FINA TECH

Low-density PPE composite material and a preparation method and application thereof

The invention discloses a low-density PPE composite material and a preparation method and application thereof. The composite material is prepared from, by weight, 30-60 parts of polyphenylene ether resin, 20-50 parts of polystyrene resin, 6-20 parts of a flammable agent, 3-8 parts of a styrene-butadiene-styrene triblock copolymer, 0.4-1 part of an antioxidant, 0.2-0.5 part of an anti-drip agent and 0.2-0.5 part of a lubricating agent. The PPE composite material has a low density characteristic, thereby being conveniently manufactured into a battery assembly.

Owner:ORINKO NEW MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com