Antiskid wear-resistant rubber sole and preparation method thereof

A rubber sole, slippery and wear-resistant technology, applied in the field of sole materials, can solve problems such as poor anti-skid performance of the sole, easy water accumulation and freezing on the road surface, easy slipping and wrestling, etc., to achieve improved toughness and strength, enhanced reinforcement effect, good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

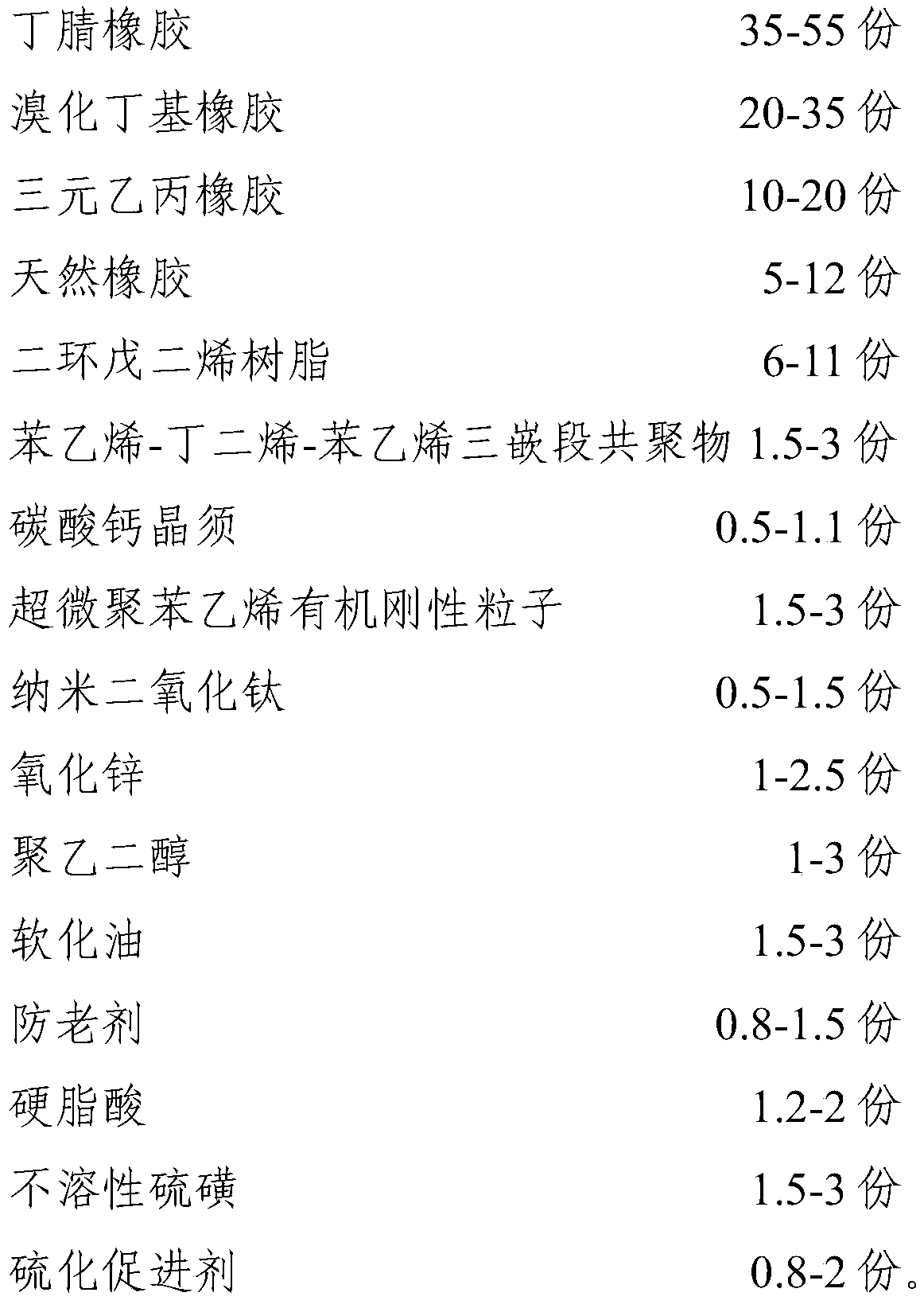

[0034] A kind of anti-slip wear-resistant rubber sole, comprises the raw material of following parts by weight:

[0035]

[0036]

[0037] The aspect ratio of calcium carbonate whiskers is 7-16; ultrafine polystyrene organic rigid particles are prepared by emulsion polymerization, and the average particle diameter of ultrafine polystyrene organic rigid particles is D 50 It is 1.02m.

[0038] The preparation method of antiskid wear-resistant type rubber sole comprises the following steps:

[0039] (1) Weigh each raw material according to the proportion; mix nitrile rubber, brominated butyl rubber, EPDM rubber, 3L standard rubber, dicyclopentadiene resin, styrene-butadiene-styrene triblock The copolymer and calcium carbonate whiskers are placed in an internal mixer for mixing; debinding is performed at 140°C to obtain a masterbatch;

[0040] (2) Place one section of masterbatch, ultrafine polystyrene organic rigid particles, nano-titanium dioxide, zinc oxide, polyethylen...

Embodiment 2

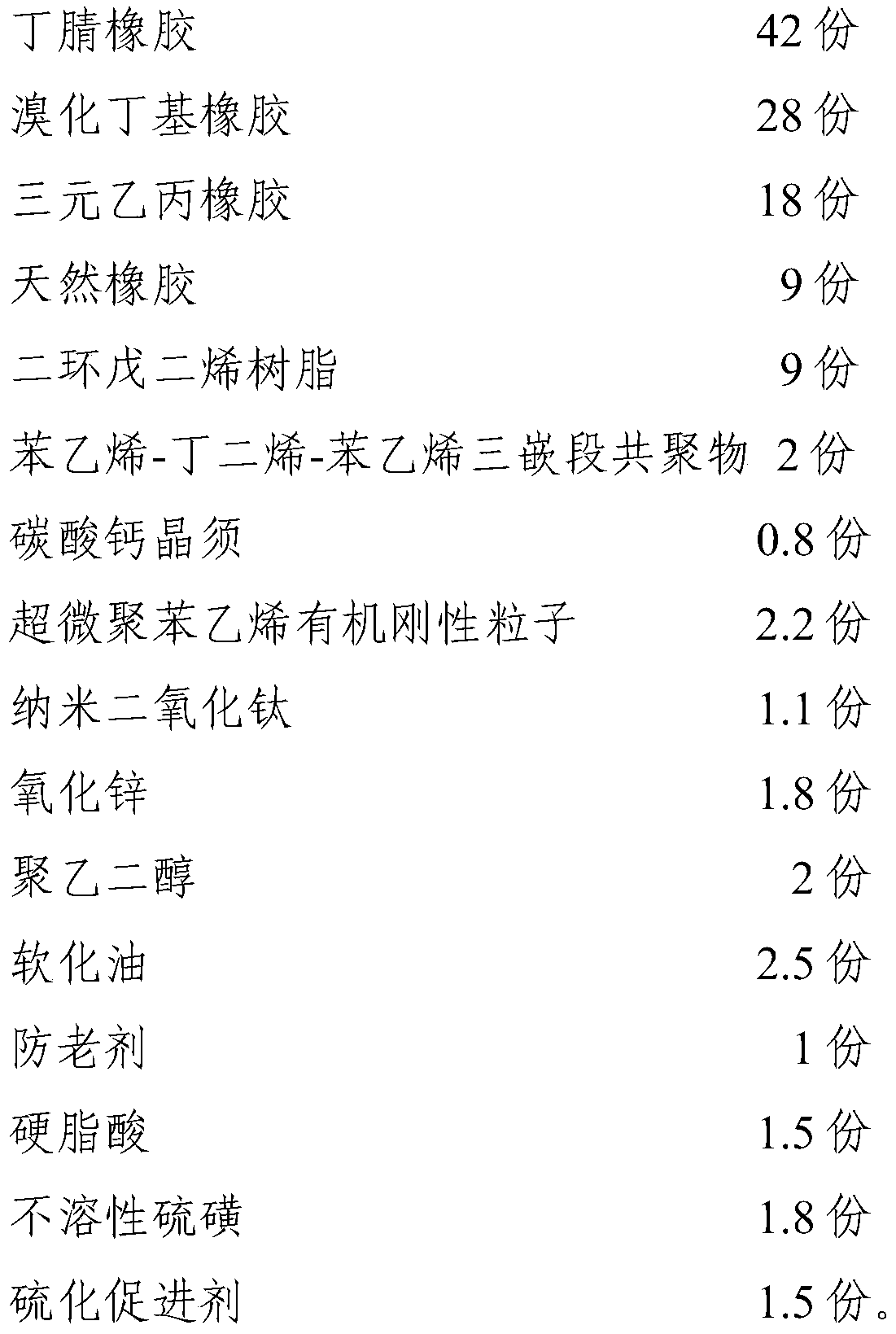

[0044] A kind of anti-slip wear-resistant rubber sole, comprises the raw material of following parts by weight:

[0045]

[0046] The aspect ratio of calcium carbonate whiskers is 7-16; ultrafine polystyrene organic rigid particles are prepared by emulsion polymerization, and the average particle diameter of ultrafine polystyrene organic rigid particles is D 50 is 0.75 μm.

[0047] The preparation method of antiskid wear-resistant type rubber sole comprises the following steps:

[0048] (1) Weigh each raw material according to the proportion; copolymerize nitrile rubber, brominated butyl rubber, EPDM rubber, natural rubber, dicyclopentadiene resin, and styrene-butadiene-styrene triblock The mixture and calcium carbonate whiskers were placed in an internal mixer for mixing; debinding was performed at 135°C to obtain a section of masterbatch;

[0049] (2) Place a section of masterbatch, ultrafine polystyrene organic rigid particles, nano-titanium dioxide, zinc oxide, polyet...

Embodiment 3

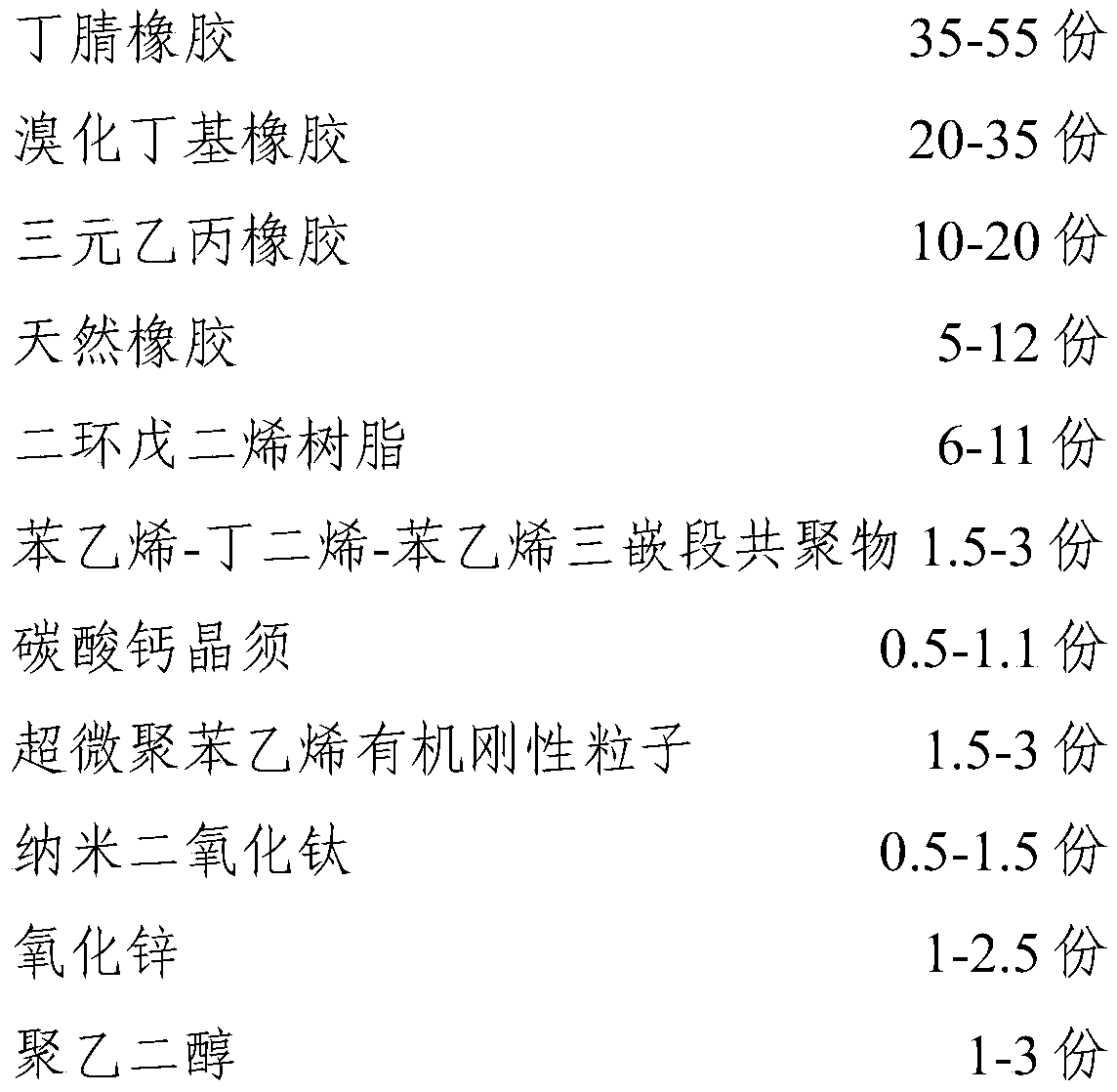

[0053] A kind of anti-slip wear-resistant rubber sole, comprises the raw material of following parts by weight:

[0054]

[0055] The aspect ratio of calcium carbonate whiskers is 7-16; ultrafine polystyrene organic rigid particles are prepared by emulsion polymerization, and the average particle diameter of ultrafine polystyrene organic rigid particles is D 50 is 0.75 μm.

[0056] The preparation method of antiskid wear-resistant type rubber sole comprises the following steps:

[0057] (1) Weigh each raw material according to the proportion; mix nitrile rubber, brominated butyl rubber, EPDM rubber, 3L standard rubber, dicyclopentadiene resin, styrene-butadiene-styrene triblock The copolymer and calcium carbonate whiskers are placed in an internal mixer for mixing; debinding is performed at 140°C to obtain a masterbatch;

[0058] (2) Place a section of masterbatch, ultrafine polystyrene organic rigid particles, nano-titanium dioxide, zinc oxide, polyethylene glycol 6000, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com