Premix and copolymerization type asphalt mixture compound modifier and preparation method thereof

A compound modifier and asphalt mixture technology, which is applied in building insulation materials, building components, buildings, etc., can solve the problems of limited modification effect and high cost, and achieve the goals of improving compatibility, increasing anti-oxidation and reducing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

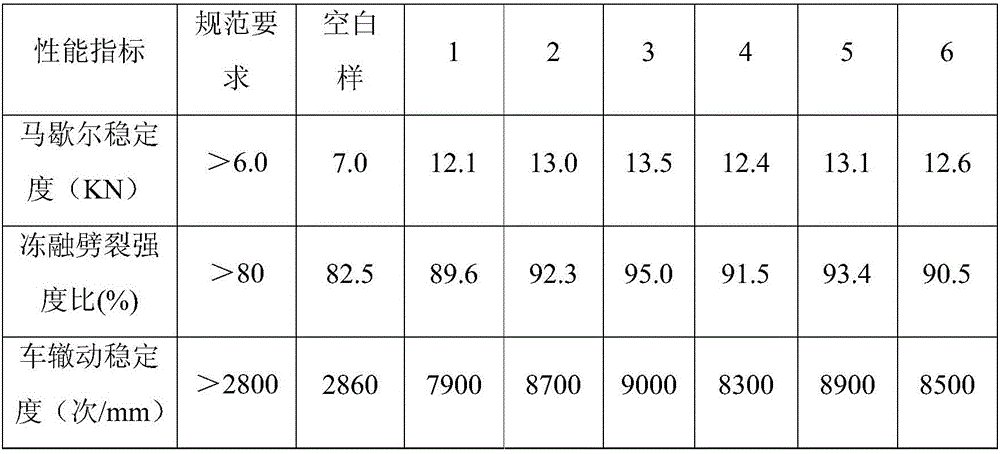

Examples

Embodiment 1

[0018] The polyethylene particles (high-density polyethylene particles, low-density polyethylene particles, linear low-density polyethylene particles are mixed at a ratio of 1:1:1) and glycidyl methacrylate are weighed at a mass ratio of 100:5. Mechanically stir and mix evenly, and react at 90° C. for 1 hour to prepare modified polyethylene particles.

[0019] Mix waste rubber powder (ordinary waste tires ground into 50 mesh rubber powder) and naphthenic rubber oil at a mass ratio of 100:5, and mechanically stir at 90°C for 50 minutes to obtain activated modified waste rubber powder.

[0020] Preparation of premixed copolymerized asphalt mixture composite modifier (10Kg): weigh 70% of the above-mentioned modified polyethylene particles, 20% of activated modified waste rubber powder, and 10% of SBS asphalt modifier according to weight ratio. Mechanically mix evenly at room temperature, add to the twin-screw extruder, control the reaction temperature at about 180°C, melt and ext...

Embodiment 2

[0022] The polyethylene particles (high-density polyethylene particles, low-density polyethylene particles, linear low-density polyethylene particles are mixed at a ratio of 1:1:1) and glycidyl methacrylate are weighed at a mass ratio of 100:5. Mechanically stir and mix evenly, and react at 90° C. for 1 hour to prepare modified polyethylene particles.

[0023] Mix waste rubber powder (ordinary waste tires ground into 50 mesh rubber powder) and naphthenic rubber oil at a mass ratio of 100:5, and mechanically stir at 90°C for 50 minutes to obtain activated modified waste rubber powder.

[0024] Preparation of premixed copolymerized asphalt mixture composite modifier (10Kg): weigh 65% of the above-mentioned modified polyethylene particles, 25% of activated modified waste rubber powder, and 10% of SBS asphalt modifier according to weight ratio. Mechanically mix evenly at room temperature, add to the twin-screw extruder, control the reaction temperature at about 200°C, melt and ext...

Embodiment 3

[0026] The polyethylene particles (high-density polyethylene particles, low-density polyethylene particles, linear low-density polyethylene particles are mixed at a ratio of 1:1:1) and glycidyl methacrylate are weighed at a mass ratio of 100:5. Mechanically stir and mix evenly, and react at 100° C. for 1 hour to prepare modified polyethylene particles.

[0027] Mix waste rubber powder (ordinary waste tires ground into 100 mesh rubber powder) and naphthenic rubber oil at a mass ratio of 100:5, and mechanically stir at 100°C for 60 minutes to obtain activated modified waste rubber powder.

[0028] Preparation of premixed copolymerized asphalt mixture composite modifier (10Kg): weigh 65% of the above-mentioned modified polyethylene particles, 20% of activated modified waste rubber powder, and 15% of SBS asphalt modifier according to weight ratio. Mechanically mix evenly at room temperature, add to the twin-screw extruder, control the reaction temperature at about 200°C, melt and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com