Flexible pipe material for temperature resistant and thermoplastic elastomer and preparation method thereof

A thermoplastic elastomer and polyolefin elastomer technology, used in hoses, pipes, machinery and equipment, etc., can solve the problems of complex process, high cost and high material cost, and achieve perfect chemical cross-linking structure, good aging resistance and weather resistance. , good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

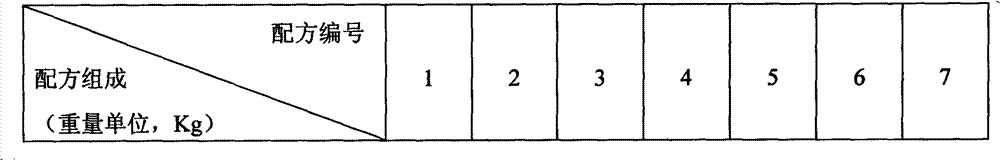

[0047] The POE and EPDM with different mass ratios were weighed according to the formula in Table 1, and the PP, DCP, TAIC with the same mass ratio were also weighed according to the formula in Table 1. According to the formula in Table 1, add POE and EPDM in different proportions into a low-speed mixer and stir evenly at normal temperature and pressure, and then add into a twin-screw extruder for blending, extrusion and granulation. Add the blended material into a low-speed mixer, add the cross-linking agent DCP and the auxiliary cross-linking agent TAIC while stirring, and the cross-linking agent has been completely absorbed and uniform. The mixed material is added to the twin-screw extruder, and the dynamic vulcanization reaction is carried out to extrude and granulate to obtain the dynamic vulcanization master batch. The dynamic vulcanization masterbatch is naturally placed at room temperature for 24 hours, then baked in a vacuum oven for 2 hours, and then taken out and pl...

Embodiment 2

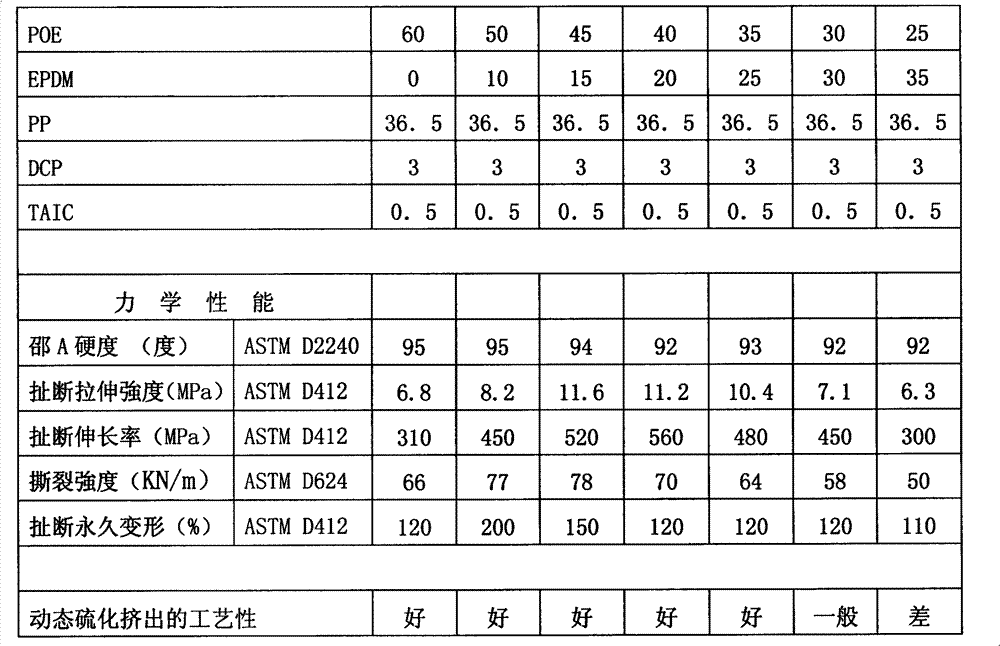

[0054] The POE, EPDM, PP, TAIC of the same mass ratio were weighed according to the formula in Table 2, and the DCP of different mass ratios was also weighed according to the formula in Table 2. According to Table 2, the formulations with different numbers are combined into dynamic vulcanization master batches, respectively, to obtain dynamic vulcanization master batches from No. 1 to No. 6 formulations in Table 2. Then, the No. 1 to No. 6 masterbatches were injection-molded into standard test samples by an injection molding machine, and tested according to the test standards in Table 2. The test results are shown in Table 2.

[0055] Table 2.

[0056]

[0057]

[0058] As shown in the results in Table 2, from the comprehensive consideration of mechanical properties and processing technology, formulations No. 3 to No. 4 perform relatively well. For example, in terms of weight percentage, the amount of POE is 45%, EPDM The dosage is 15%, PP is 36.5-37.5%, DCP is 2-3%, T...

Embodiment 3

[0060] The No. 3 formula in Table 1 or the No. 4 formula in Table 2 is made into a dynamic vulcanization master batch, for subsequent use.

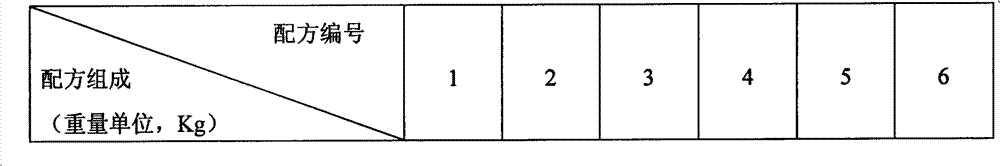

[0061] As shown in 6 groups of formulas in Table 3, SEBS, rubber oil, calcium carbonate and the above-mentioned self-made dynamic vulcanization masterbatch with different mass ratios were weighed respectively. Put SEBS into a low-speed mixer, heat and stir at 60-100°C, and add plasticizer rubber oil. After the rubber oil is fully absorbed, add dynamic vulcanization masterbatch and filler material calcium carbonate, and stir evenly. The mixture is then added to a twin-screw extruder for physical blending, extrusion and granulation to obtain a finished thermoplastic elastomer hose material.

[0062] The finished particles of No. 1 to No. 6 were injected into standard test samples by injection molding machine. Injection parameters: temperature 190-210°C, pressure 50-75MPa, mold temperature 50°C. After placing the standard test sample in an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com