Preparation method and special mold for building self-insulating non-load-bearing wall blocks

A self-insulating, non-load-bearing technology, used in molds, manufacturing tools, ceramic forming cores, etc., can solve the problems of easily broken blocks, limited block strength, and low yield, achieve stable physical and chemical properties, and reduce overall production costs. , The effect of strong aging resistance and weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] A method for preparing self-insulating non-load-bearing wall blocks for construction, characterized in that it is prepared according to the following steps:

[0027] (1) Mixer mixing concrete: prepare according to the ratio in the table

[0028]

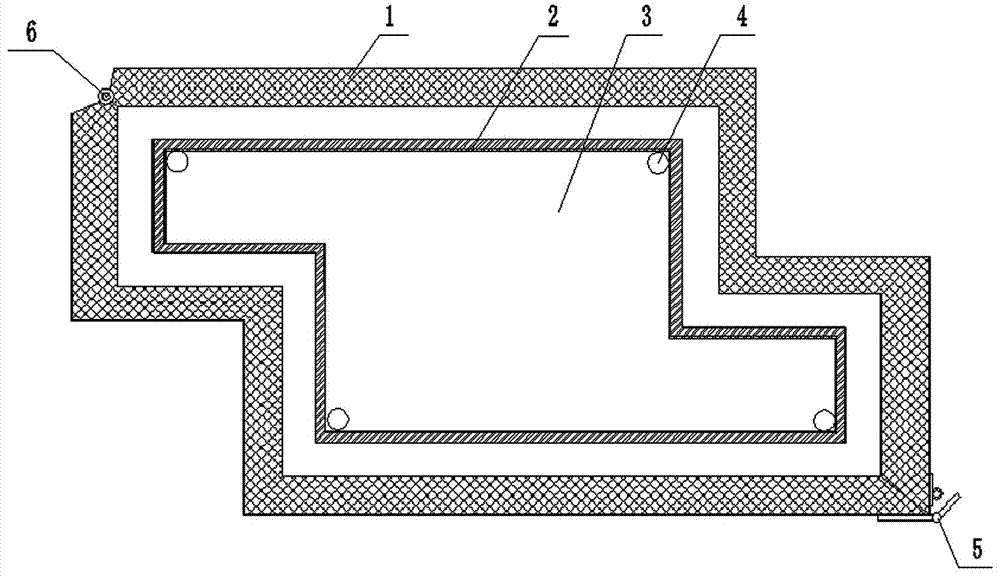

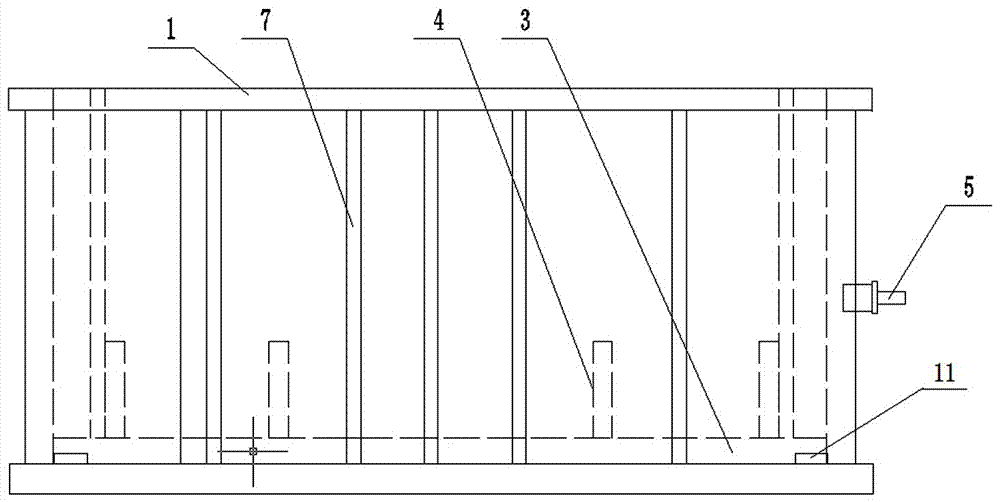

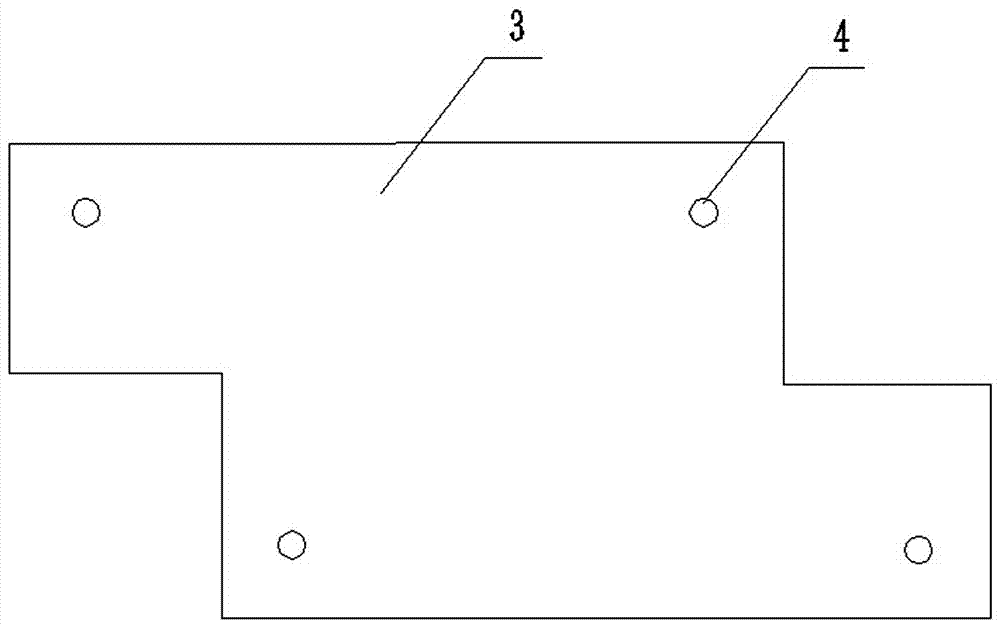

[0029] (2) Prepare a special mold: the special mold includes an outer mold, a bottom plate, an inner mold, and a distribution hopper. The mold is placed on a vibration platform, the bottom plate is placed at the bottom of the outer mold, and the inner mold is positioned in the outer mold through the positioning column on the bottom plate. The distribution hopper is placed on the outer mold through its positioning device with the edge of the outer mold, so that the outlet of the distribution hopper corresponds to the pouring cavity formed by the inner mold of the outer mold;

[0030] (3) Filling the mold: pouring concrete into the inner cavity of the mold through the distribution hopper;

[0031] (4) Vibration: Start the vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com