Beta-cyclodextrin/styrene-butadiene-styrene triblock copolymer modified asphalt and preparation method thereof

A technology of copolymer modification and styrene, applied in building structures, building components, building insulation materials, etc., can solve the problems of unstable performance, three-dimensional network breakage, degradation, etc., and achieves low price, simple process, and difficult the effect of reunion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] 300g of 90 # Melt the base asphalt in a 500mL beaker, put the beaker into a well-type sand bath heating furnace, the processing temperature is 155°C, put the shearer into the base asphalt, adjust the speed to 3500rpm, weigh 12g of SBS and add it to the base asphalt Shear dispersion, the addition time is 5min.

[0048] Weigh 3g of β-CD and pour it into a beaker filled with 9g of DMF. Heat the mixed solution in a water bath at 75°C with constant stirring. When there are no more solid substances in the mixed solution, pour it into the prefabricated SBS modified asphalt , using a high-speed shearing machine to shear for 50 minutes, the shearing speed is 3500 rpm, and the shearing temperature is 155°C. After the shearing is completed, the shearing machine is taken out, and the modified asphalt is put into an oven at 170°C to develop for 60 minutes, and the β-CD / SBS modified asphalt of the present invention is obtained.

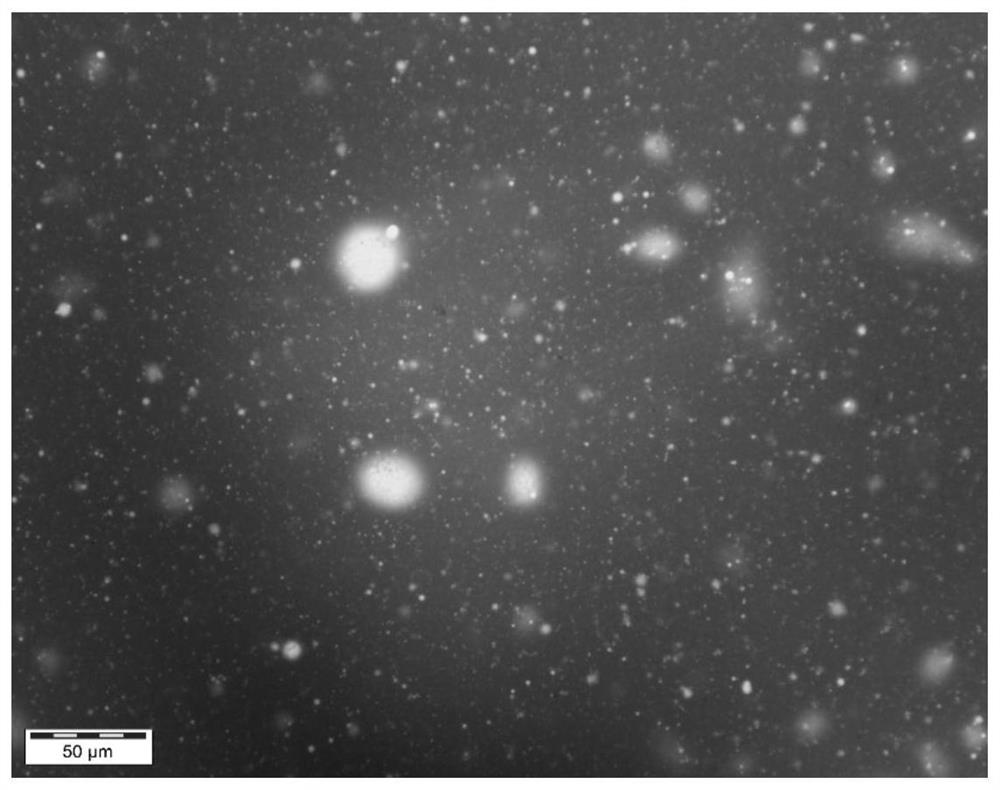

[0049] Utilize the fluorescence microscope to observ...

Embodiment 2

[0051] 400g of 90 # Melt the base asphalt in a 500mL beaker, put the beaker into a well-type sand bath heating furnace, the processing temperature is 160°C, put the shearer into the base asphalt, adjust the speed to 3750rpm, weigh 16g of SBS and add it to the base asphalt Shear dispersion, the addition time is 7min.

[0052] Weigh 12g of β-CD and pour it into a beaker filled with 36g of DMF. Heat the mixed solution in a water bath at 80°C with constant stirring. When there are no more solid substances in the mixed solution, pour it into the prefabricated SBS modified asphalt In the process, the high-speed shearing machine was used to shear for 60 minutes, the shearing speed was 3750 rpm, and the shearing temperature was 160°C. After the shearing is completed, the shearing machine is taken out, and the modified asphalt is put into an oven at 165°C to develop for 60 minutes, and the β-CD / SBS modified asphalt of the present invention is obtained.

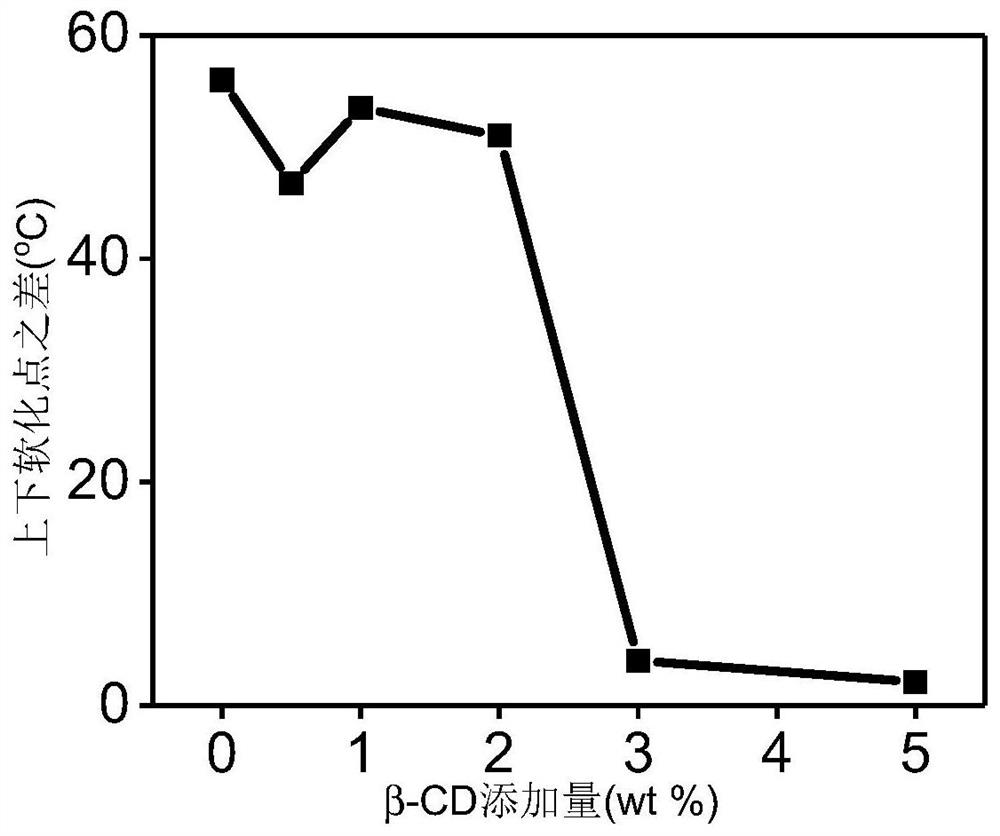

[0053] At this point, the SBS...

Embodiment 3

[0055] Melt 500g of 90# base asphalt in a 600mL beaker, put the beaker into a well-type sand bath heating furnace, the processing temperature is 165°C, put the shearer into the base asphalt, adjust the speed to 4000rpm, and weigh 20g of SBS Add to the base asphalt for shear dispersion, and the adding time is 10 minutes.

[0056] Weigh 25g of β-CD and pour it into a beaker filled with 75g of DMF. Heat the mixed solution in a water bath at 80°C with constant stirring. When there are no more solid substances in the mixed solution, pour it into the prefabricated SBS modified asphalt In the process, the high-speed shearing machine was used to shear for 55 minutes, the shearing speed was 4000 rpm, and the shearing temperature was 165°C. After the shearing is completed, take out the shearing machine, and put the modified asphalt in an oven at 170°C for 70 minutes to obtain β-CD / SBS modified asphalt.

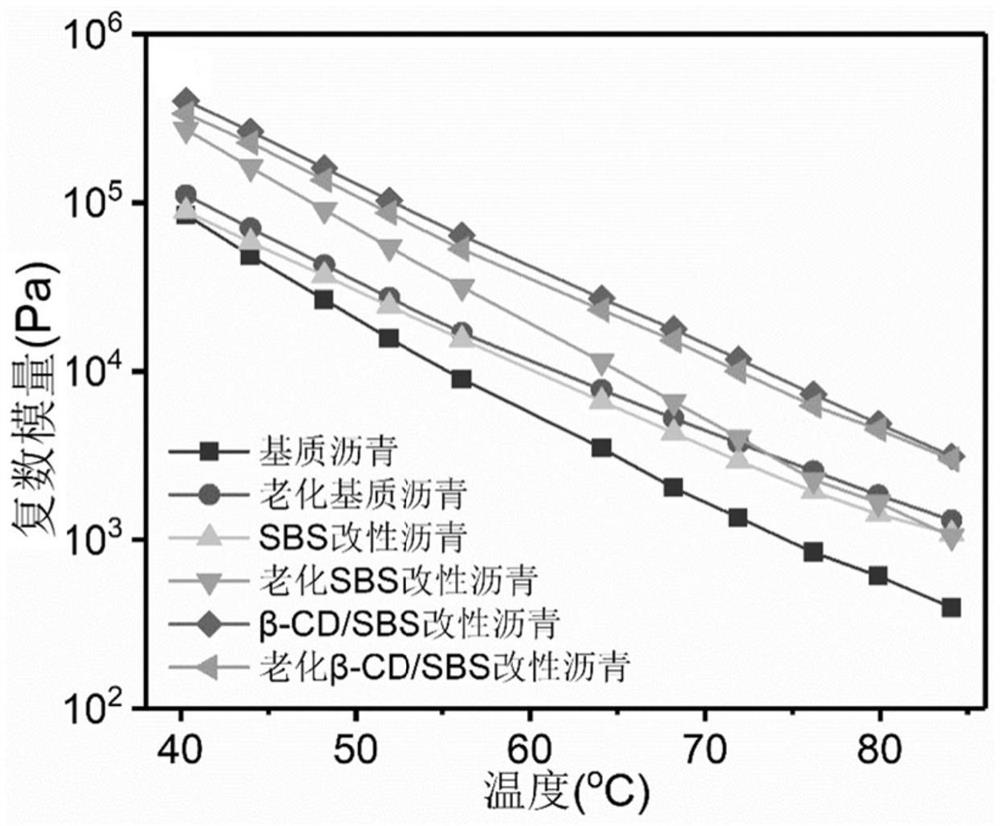

[0057] The rheological characteristic curve of embodiment 3 gained β-CD / SBS modifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com