Modified bamboo fiber reinforced anti-aging styrene-butadiene rubber and preparation method thereof

A technology of styrene-butadiene rubber and bamboo fiber, which is applied in the field of rubber materials, can solve the problems of slow reaction speed, poor ozone resistance, and low strength, and achieve the effects of enhanced polarity, sufficient intercalation power, and excellent tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

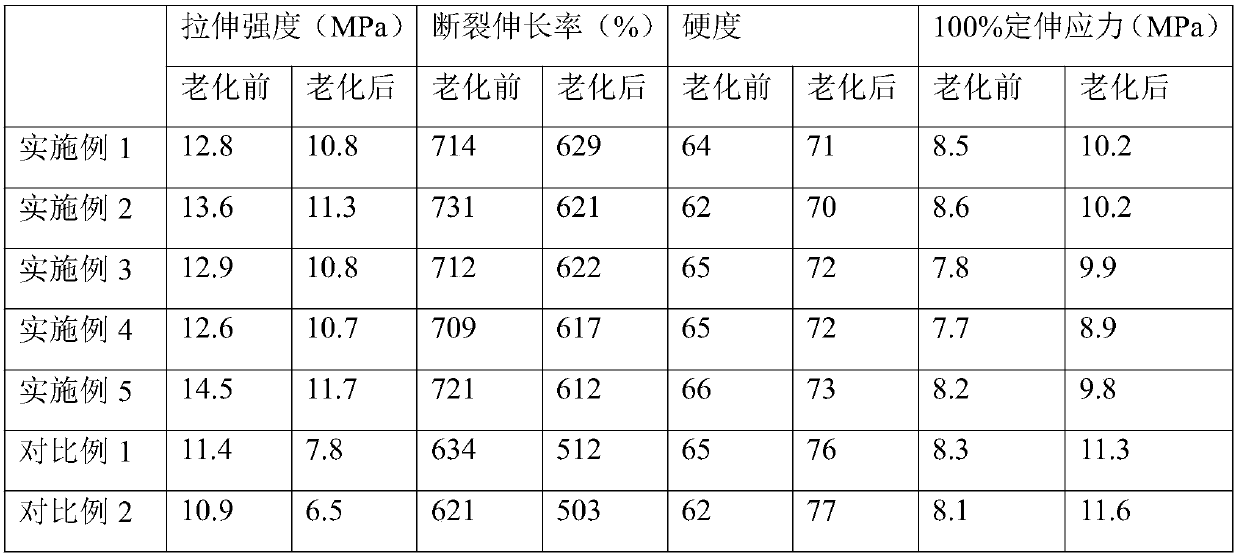

Examples

Embodiment 1

[0012] A modified bamboo fiber reinforced anti-aging styrene butadiene rubber, comprising the following steps: 100 parts of styrene butadiene rubber, 20 parts of carbon black, 2 parts of zinc oxide, 0.5 parts of stearic acid, 0.5 parts of accelerator D, and TMTD of accelerator 1.5 parts, 3 parts of antioxidant 4020, 1 part of sulfur, 10 parts of modified bamboo fiber, 5 parts of γ-glycidoxypropyltrimethoxysilane modified zinc oxide, 15 parts of modified polarized PSBS 8331 ;

[0013] Among them, the preparation method of the modified bamboo fiber is to dry the chemical bamboo pulp fiber at 100°C, and then add it to the mixed aqueous solution of N-methylol acrylamide and sulfuric acid to soak, and the concentration of the mixed aqueous solution of N-methylol acrylamide It is 2.5% and the concentration of sulfuric acid is 0.5%. After soaking for 1 min, take it out and dry it.

[0014] The above-mentioned method for preparing modified bamboo fiber reinforced anti-aging styrene-butadi...

Embodiment 2

[0016] A modified bamboo fiber reinforced anti-aging styrene butadiene rubber, comprising the following steps: 200 parts of styrene butadiene rubber, 30 parts of carbon black, 4 parts of zinc oxide, 2 parts of stearic acid, 1.5 parts of accelerator D, and TMTD of accelerator 0.5 parts, antioxidant 4020 6 parts, sulfur 2.5 parts, modified bamboo fiber 20 parts, γ-glycidoxypropyltrimethoxysilane modified zinc oxide 10 parts, modified polarized PSBS8231 25 parts;

[0017] Among them, the preparation method of the modified bamboo fiber is to dry the chemical bamboo pulp fiber at 100°C, and then add it to the mixed aqueous solution of N-methylol acrylamide and sulfuric acid to soak, and the concentration of the mixed aqueous solution of N-methylol acrylamide It is 6% and the concentration of sulfuric acid is 1.5%. After soaking for 5 minutes, take it out and dry it.

[0018] The above-mentioned method for preparing modified bamboo fiber reinforced anti-aging styrene-butadiene rubber, fi...

Embodiment 3

[0020] A modified bamboo fiber reinforced anti-aging styrene butadiene rubber, comprising the following steps: 120 parts of styrene butadiene rubber, 25 parts of carbon black, 2 parts of zinc oxide, 0.8 parts of stearic acid, 0.8 parts of accelerator D, and accelerator TMTD: 0.5 parts, 4 parts of antioxidant 4020, 1.5 parts of sulfur, 12 parts of modified bamboo fiber, 6 parts of γ-glycidoxypropyltrimethoxysilane modified zinc oxide, 15 parts of modified polarized PSBS8331;

[0021] Among them, the preparation method of the modified bamboo fiber is to dry the chemical bamboo pulp fiber at 100°C, and then add it to the mixed aqueous solution of N-methylol acrylamide and sulfuric acid to soak, and the concentration of the mixed aqueous solution of N-methylol acrylamide It is 3.5% and the concentration of sulfuric acid is 0.8%. After soaking for 1 min, take it out and dry it.

[0022] The above-mentioned method for preparing modified bamboo fiber reinforced anti-aging styrene-butadien...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com