SBS (styrene-butadiene-styrene triblock copolymer) and liquid rubber composite modified emulsified asphalt and preparation method thereof

A compound modified asphalt and liquid rubber technology, which is applied in building components, building insulation materials, buildings, etc., can solve the problems of limited road performance improvement, poor product stability, and difficult emulsification of modified emulsified asphalt with high solid content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

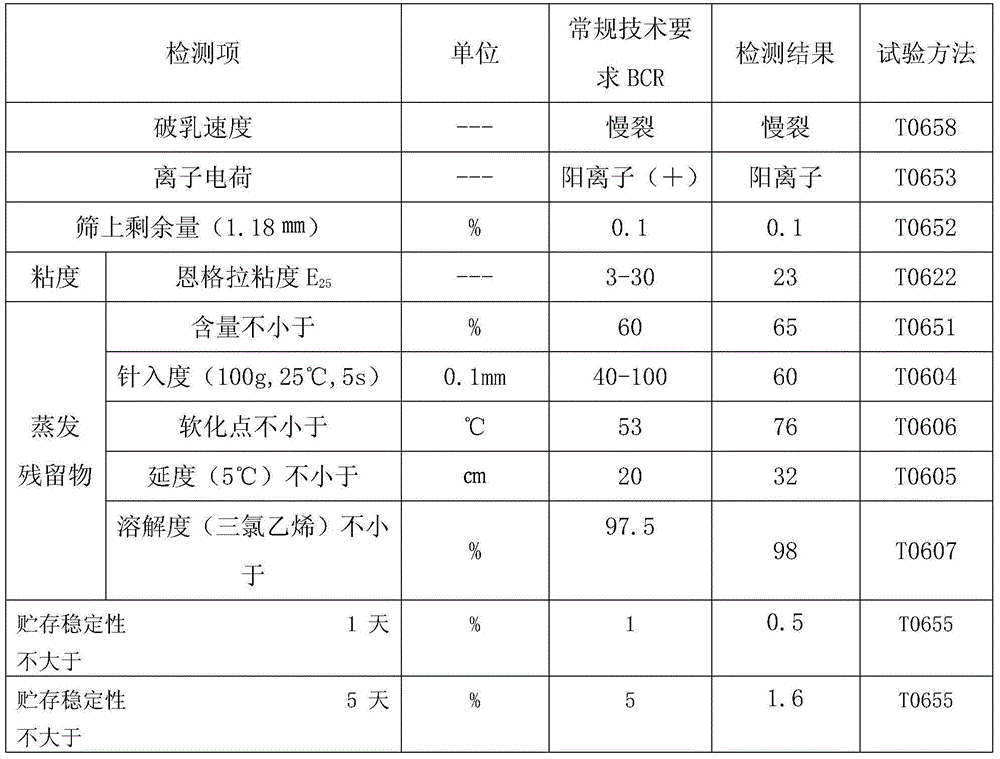

[0026] Add 118.4g homemade paste liquid rubber and 23.6g solid linear SBS to 592g

[0027] SK90 # In the hot asphalt, the temperature is controlled at 180℃, the stirring is developed for 40 minutes, the stirring speed is 300 rpm, the shearing is 20 minutes, the shearing speed is 3500 rpm, and the 0.63g crosslinking agent is added under rapid stirring, the stirring speed is 500 rpm, and the stirring After 4 hours, SBS and liquid rubber composite modified asphalt were prepared; in addition, 16.1g of cationic emulsifier of MedVistvac, 6.3g of nonionic surfactant, 3.8g of calcium chloride, 2.0g of magnesium chloride, and the mixture was added to After mixing 248g of water at 60°C evenly, adjust the PH value to 3.0 with hydrochloric acid to prepare emulsified soap; then take 513g of the modified asphalt and 276.2g of emulsified soap prepared above and cut in a high-speed shearing machine for 25 minutes , The shear speed is 4500 min, and the SBS liquid rubber compound modified emulsifi...

Embodiment 2

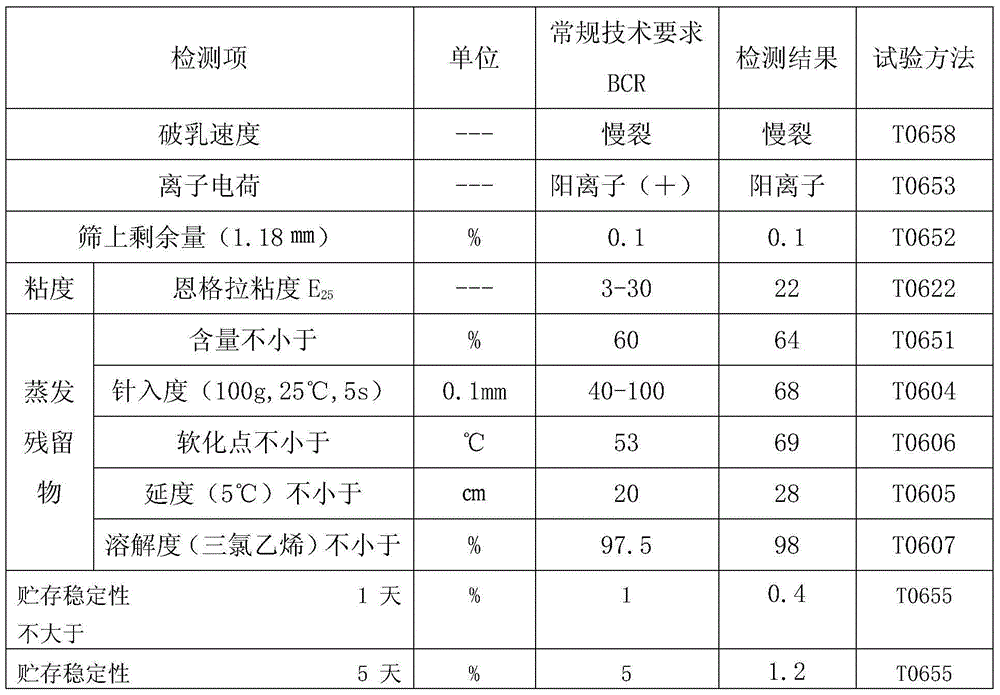

[0036] Take 78g of homemade pasty liquid rubber and 15.6g of solid linear SBS and add them to 520g SK70. # In the hot asphalt, the temperature is controlled at 180℃, the stirring is developed for 40 minutes, the stirring speed is 300 rpm, the shearing is 20 minutes, the shearing speed is 3500 rpm, and the 0.62g crosslinking agent is added under rapid stirring. In 4 hours, SBS and liquid rubber composite modified asphalt were prepared; in addition, 13.2g of cationic emulsifier, 5.0g of non-ionic surfactant, 2.3g of ammonium chloride and 2.0g of calcium chloride were added to After mixing 268g of 60℃ water evenly, adjust the PH value to 3.0 with hydrochloric acid to prepare emulsified soap; then take 500g of the modified asphalt and 290g of emulsified soap prepared above and cut in a high-speed shearing machine for 25 minutes, The SBS liquid rubber compound modified emulsified asphalt can be prepared at a shear speed of 4500 rpm.

[0037] The preparation of the above-mentioned past...

Embodiment 3

[0044] Take 40g of homemade paste liquid rubber and 10g of solid linear SBS and add them to 400g SK90. # In the hot asphalt, the temperature is controlled at 180℃, the stirring is developed for 40 minutes, the stirring speed is 300 rpm, shearing is 20 minutes, the shearing speed is 3500 rpm, and 0.48g of crosslinking agent is added under rapid stirring, and the stirring speed is 500 rpm, stirring After 4 hours, SBS and liquid rubber composite modified asphalt were prepared; in addition, 12.4g of cationic emulsifier, 4.8g of nonionic surfactant, 3.0g of calcium chloride and 1.0g of ferric chloride were added to After mixing 490g of water at 60°C evenly, adjust the PH value to 3.0 with hydrochloric acid to prepare emulsified soap; then take 410g of the modified asphalt and 269g of emulsified soap prepared above and cut in a high-speed shearing machine for 25 minutes, The SBS liquid rubber compound modified emulsified asphalt can be prepared at a shear speed of 4500 rpm.

[0045] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com