Color bituminous cement in bags or barrels and production device and method thereof

A technology for colored asphalt and cementitious materials, applied in the field of pavement materials, can solve the problems of low relative efficiency, long production cycle, complex process, etc., and achieve the effects of convenient operation, high qualification rate, and stable product quality and performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

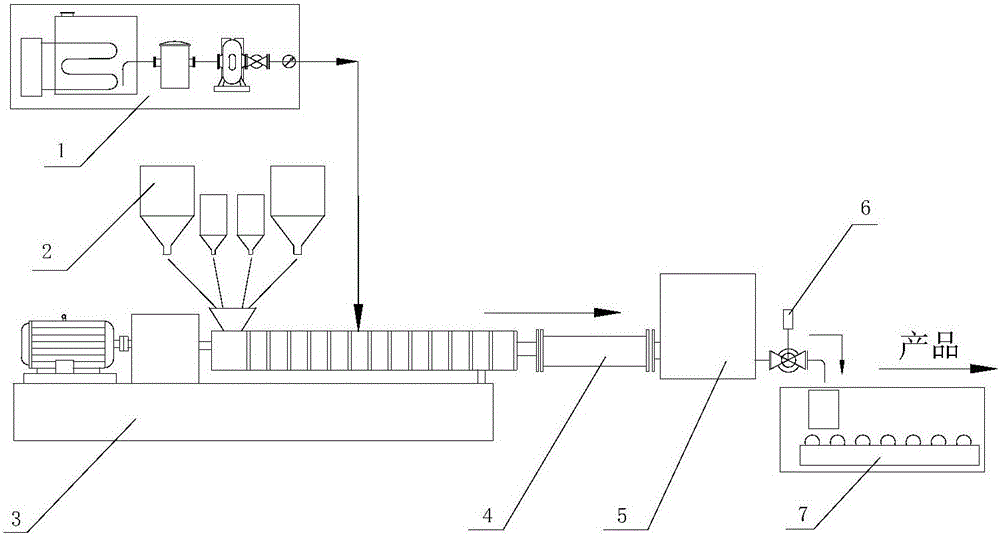

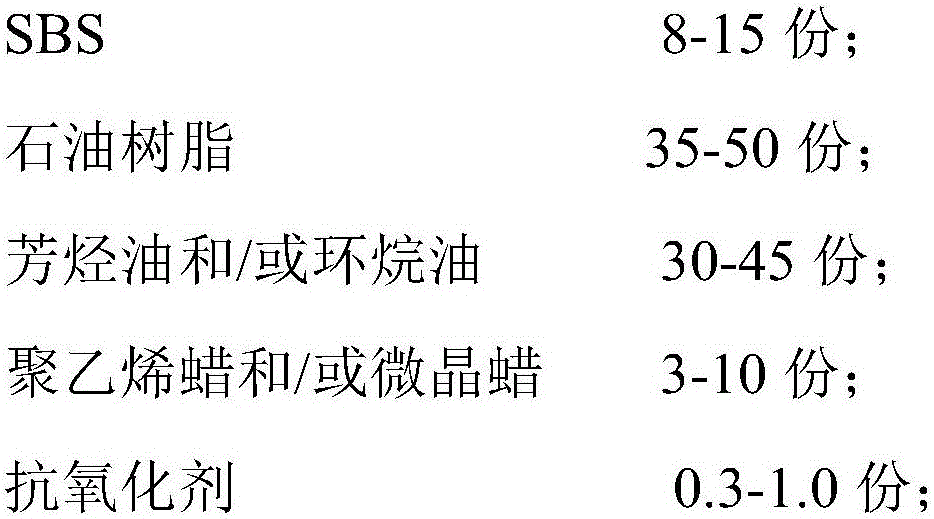

[0042] Add 40 parts by weight of trimethylbenzene to the screw extruder through the liquid material weighing system, and weigh 10 parts of SBS, 40 parts of C5 petroleum resin, 9 parts of H1001 polyethylene wax, and 1 part of antioxidant 1010 through the powder material. The heavy system is added to the twin-screw extruder, and the twin-screw extruder is preheated to 200 ° C. Under the action of the screw and kneading block in the machine, the materials are mixed, melted, sheared and modified, and then entered into the static mixer to make the material. The material is further mixed and plasticized, and the temperature is controlled to 160 °C, and then enters the balance tank. Through the discharge port of the balance tank, the product enters the filling and weighing system, and finally is put into a packaging bag to form a cementitious product.

Embodiment 2

[0044]Add 30 parts by weight of xylene to the screw extruder through the liquid material weighing system, and weigh 12 parts of SBS, 50 parts of C9 petroleum resin, 7 parts of H1001 polyethylene wax, and 1 part of antioxidant 1010 through the powder material. The heavy system is added to the reciprocating single-screw extruder. The reciprocating single-screw extruder is preheated to 180°C. Under the action of the screw and kneading block in the machine, the material is mixed, melted, sheared, modified, and then enters the static state. The mixer is used to further mix and plasticize the materials, and control the temperature to 150°C, and then enter the balance tank, through the discharge port of the balance tank, make the product enter the filling and weighing system, and finally put it into the packaging barrel to form a cementitious product .

Embodiment 3

[0046] 40 parts by weight of cyclopentane was added to the screw extruder through the liquid material weighing system, 15 parts of SBS, 35 parts of C9 petroleum resin, 9 parts of microcrystalline wax, and 1 part of antioxidant 1010 were weighed by the powder material. Heavy system, add twin-screw extruder, the twin-screw extruder is preheated to 160 ℃, under the action of the screw and kneading block in the machine, the material is mixed, melted, sheared, modified, and then enters the static mixer, The materials are further mixed and plasticized, and the temperature is controlled to 160°C, and then enters the balance tank. Through the discharge port of the balance tank, the product enters the filling and weighing system, and finally is packed into a packaging bag to form a cementitious product.

[0047] When in use, put 6 bags of colored asphalt binder products into a melting tank with a heating temperature of 170°C to melt, and then pump it into the mixing tank of the asphalt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com