High modulus modified asphalt and preparation method

A modified asphalt, high-modulus technology, applied in building components, building insulation materials, buildings, etc., can solve the problem that high-temperature performance cannot meet the needs of roads in high-temperature areas, cannot achieve high-modulus modified asphalt performance, and increase the difficulty of preparation. and other problems, to achieve the effect of simplifying time and equipment costs, improving high temperature resistance, and improving tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

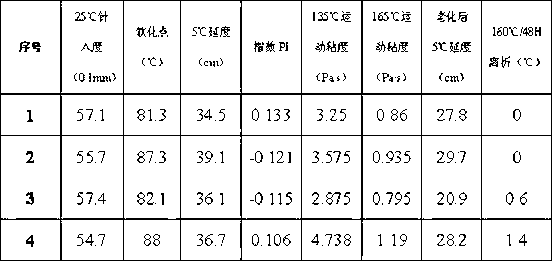

Examples

Embodiment 1

[0051] Step a: 34% polyethylene A, 52% polyethylene B, 7% ethylene terpolymer, 1% ethylene bis stearamide, 5% waste motor oil, 0.2% tris[2.4-di-tert-butylbenzene base] phosphite, 0.2% tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester and the rest of the toner were put into the powder tank in sequence for uniform stirring, and the stirring time 2~10min, the stirring speed is 600r / min.

[0052] Step b: Extrude and granulate the uniformly stirred material in step a with a twin-screw extruder, the extrusion temperature is 150~200°C, the vacuum degree during extrusion granulation is -0.08~-0.04MPa, the screw speed is It is 350r / min.

[0053] Step c: The materials prepared in the above step b are sequentially cooled by immersion in water, shaken by a water pump, pelletized by a pelletizer, and mixed by a mixing bucket, so that the physical properties of the product are uniform and the finished product is put into storage.

Embodiment 2

[0055] Step a: 82% polyethylene B, 10% ethylene terpolymer, 1% ethylene bis stearamide, 6% aromatic oil, 0.1% tris[2.4-di-tert-butylphenyl] phosphite, Put 0.2% tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester and the rest of the toner into the powder tank in turn and stir evenly. The stirring time is 2~10min. The speed is 800r / min.

[0056] Step b: Extrude and granulate the uniformly stirred material in step a with a twin-screw extruder, the extrusion temperature is 150~200°C, the vacuum degree during extrusion granulation is -0.08~-0.04MPa, the screw speed is 400r / min.

[0057] Step c: The materials prepared in the above step b are sequentially cooled by immersion in water, shaken by a water pump, pelletized by a pelletizer, and mixed by a mixing bucket, so that the physical properties of the product are uniform and the finished product is put into storage.

Embodiment 3

[0059] Step a: 82% polyethylene A, 9% ester copolymer, 1% ethylene bis stearamide, 7% mixture of waste engine oil and aromatic oil with a mass ratio of 1:1, 0.2% tri[2.4-ditert-tert Butylphenyl] phosphite, 0.2% tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester and the rest of the toner were put into the powder tank in sequence for uniform stirring , the stirring time is 2~10min, and the stirring speed is 800r / min.

[0060] Step b: Extrude and granulate the uniformly stirred material in step a with a twin-screw extruder, the extrusion temperature is 150~200°C, the vacuum degree during extrusion granulation is -0.08~-0.04MPa, the screw speed is It is 450r / min.

[0061] Step c: The materials prepared in the above step b are sequentially cooled by immersion in water, shaken by a water pump, pelletized by a pelletizer, and mixed by a mixing bucket, so that the physical properties of the product are uniform and the finished product is put into storag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com