Rubber powder-modified asphalt and preparation method thereof

A technology for modifying asphalt and rubber powder, applied in building components, building insulation materials, construction and other directions, can solve the problems of poor storage stability, incomplete improvement of matrix asphalt, affecting the performance of rubber powder modified asphalt, etc. Low temperature performance and water stability performance, ductility and segregation index improvement, the effect of solving poor storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

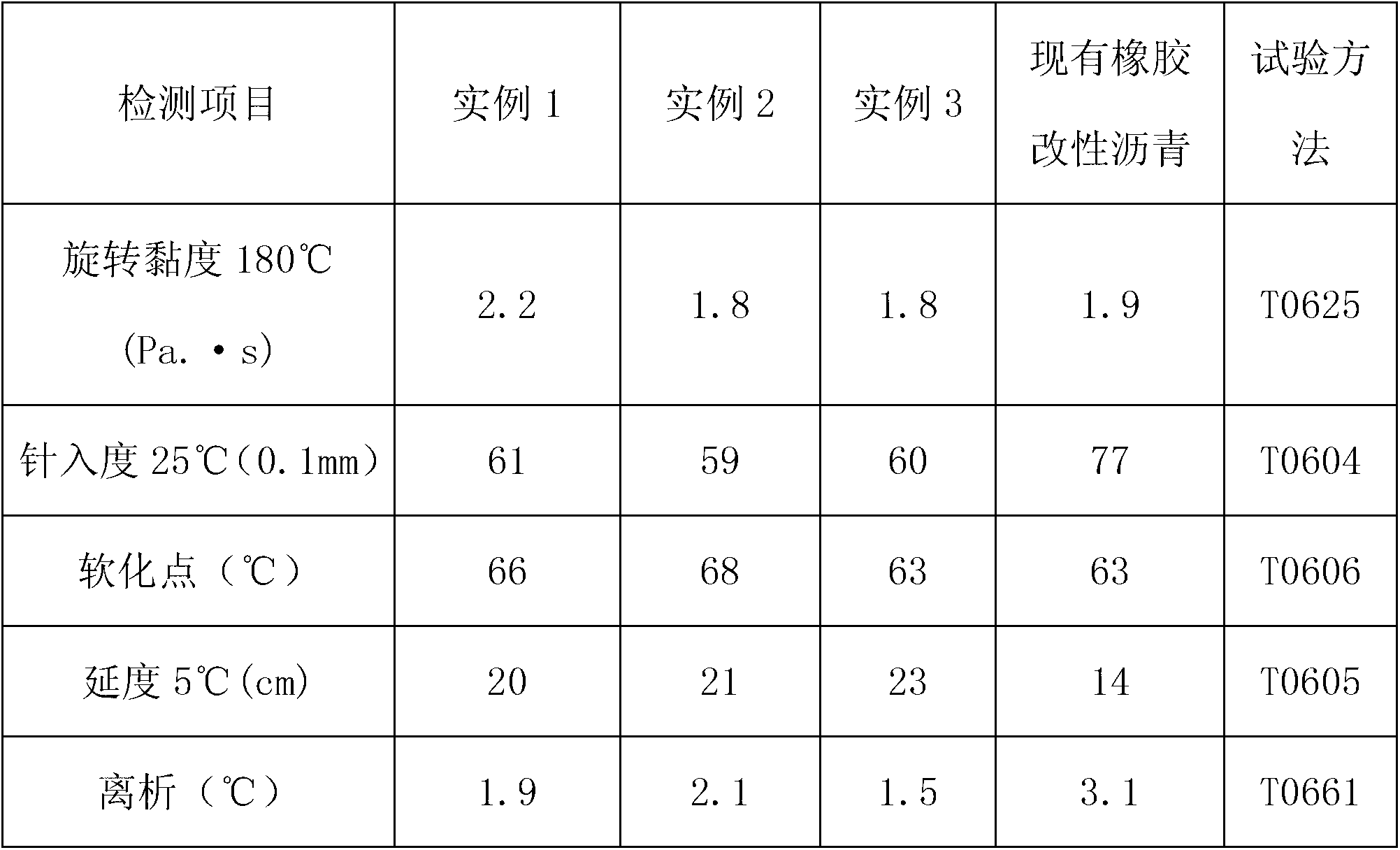

Examples

Embodiment 1

[0024] According to parts by weight, take 30 parts of 40-mesh rubber powder, 100 parts of Korean SK petroleum asphalt with a label of 70, and 1 part of styrene-butadiene-styrene triblock copolymer (SBS), produced by China Petroleum Lanzhou Petrochemical Company The rubber filler oil is 5 parts, the polyethylene grafted maleic anhydride polymer (PE-MAH) is 2 parts, and the sulfur is 3 parts.

[0025] The production process of rubber powder modified asphalt is as follows: heat petroleum asphalt to 160°C, add rubber powder into the asphalt and stir for 75 minutes at a temperature of 160°C, after the stirring is completed, mix styrene-butadiene-styrene Segment copolymer, rubber filler oil, polyethylene grafted maleic anhydride polymer (PE-MAH) and sulfur are added to it, and then sheared by a shearing machine for 30 minutes at a shearing temperature of 170 ° C, and finally in a temperature of 140 ° C Swell for 15 hours under ambient conditions to obtain rubber powder modified asph...

Embodiment 2

[0027] According to parts by weight, take 20 parts of 60-mesh rubber powder, 100 parts of Korean SK petroleum asphalt with a label of 90, and 2 parts of styrene-butadiene-styrene triblock copolymer (SBS), produced by China Petroleum Lanzhou Petrochemical Company The rubber filler oil is 4 parts, the polyethylene grafted maleic anhydride polymer (PE-MAH) is 1 part, and the sulfur is 2 parts.

[0028] The production process of rubber powder modified asphalt is to heat petroleum asphalt to 170°C, add rubber powder to the asphalt and stir for 60 minutes at a temperature of 160°C, after the stirring is completed, styrene-butadiene-styrene Segment copolymer, rubber filler oil, polyethylene grafted maleic anhydride polymer (PE-MAH) and sulfur are added to it, and then sheared by a shearing machine for 45 minutes at a shearing temperature of 170 ° C, and finally in a temperature of 130 ° C Swell for 18 hours under ambient conditions to obtain rubber powder modified asphalt.

Embodiment 3

[0030] According to parts by weight, take 15 parts of 80-mesh rubber powder, 100 parts of Korean SK petroleum asphalt with a label of 90, and 0.5 parts of styrene-butadiene-styrene triblock copolymer (SBS), produced by PetroChina Lanzhou Petrochemical Company The rubber extender oil is 2 parts, the polyethylene graft maleic anhydride polymer (PEMAH) is 0.5 parts, and the sulfur is 1 part.

[0031] The production process of rubber powder modified asphalt is to heat petroleum asphalt to 150°C, add rubber powder to the asphalt and heat and stir for 45min, the stirring temperature is 160°C, after the stirring is completed, styrene-butadiene-styrene three Block copolymer, rubber filler oil, polyethylene grafted maleic anhydride polymer (PEMAH) and sulfur were added to it, and then sheared by a shearing machine for 60 minutes at a shear temperature of 170°C, and finally in an environment with a temperature of 150°C Swell for 12 hours to obtain rubber powder modified asphalt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com