Axial-force rod piece stable lifting piece and operating method thereof

A rod and axial force technology, applied in the field of wood structure building construction, can solve the problems of complicated design selection, difficult installation and positioning, non-standard application of axial force rods, etc., to ensure shear resistance, improve allowable values, improve The effect of seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

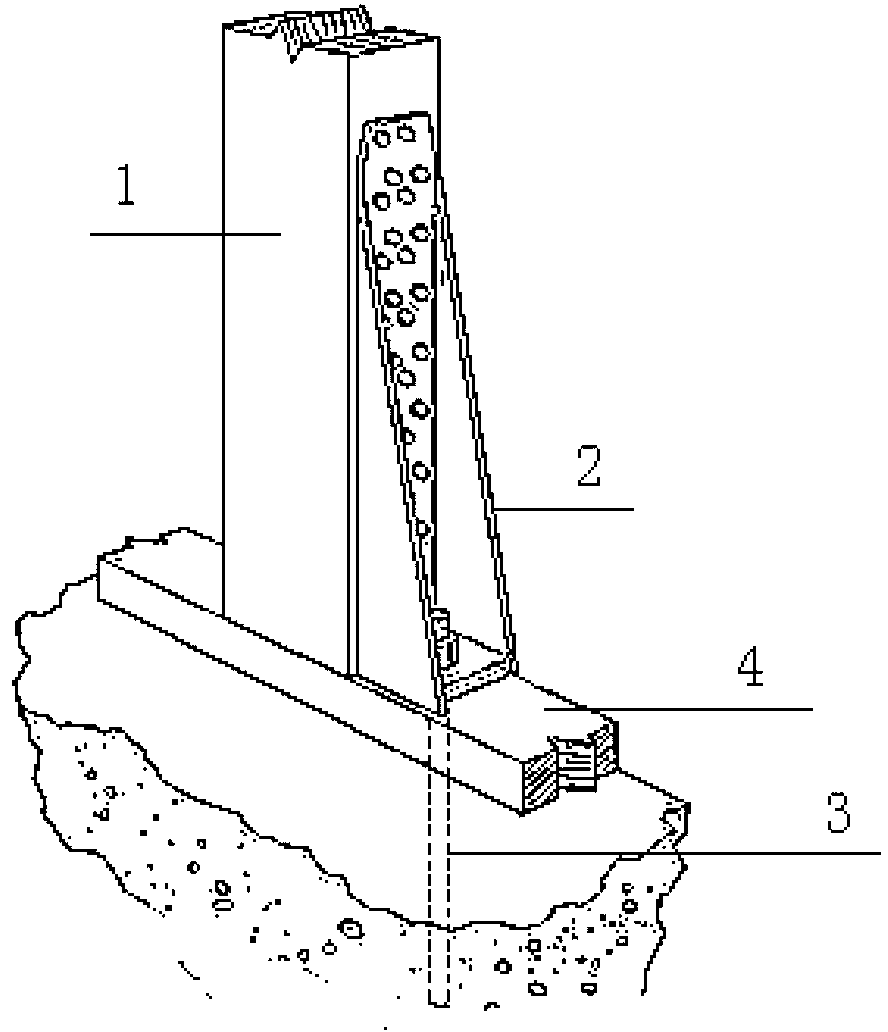

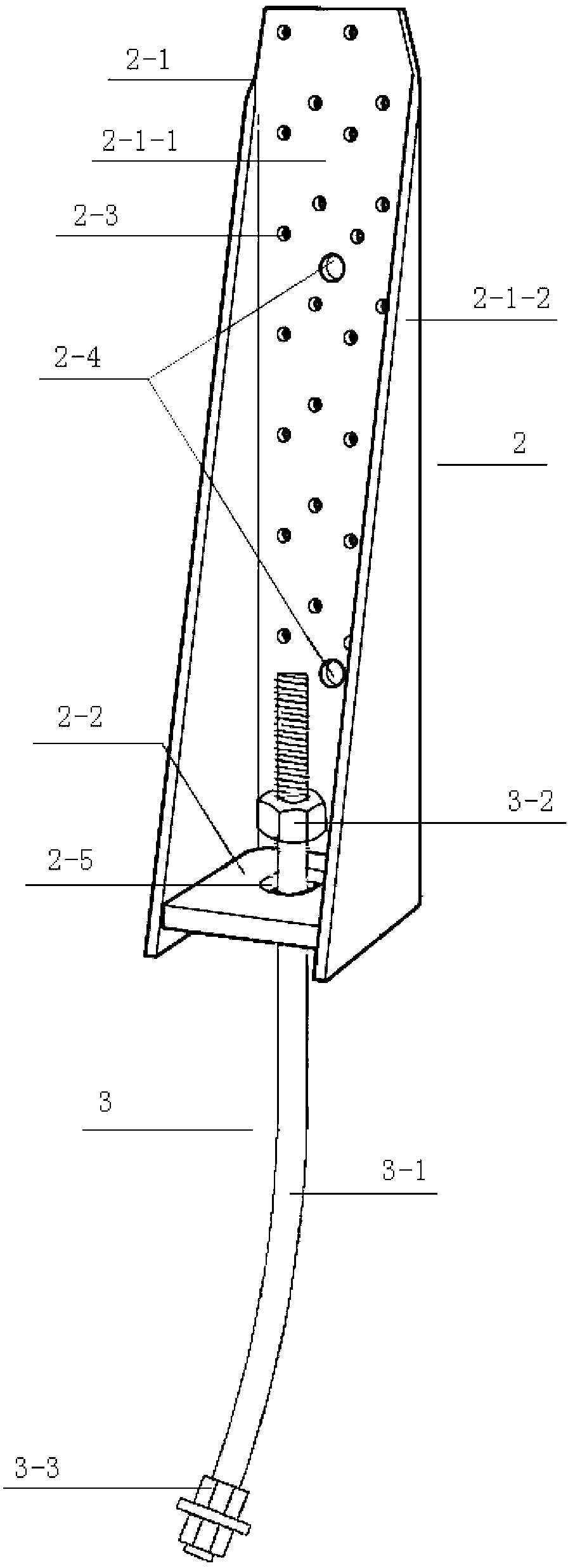

[0023] Embodiment 1: A kind of axial force rod member steady lifting member (see Figure 1-2 ), which is characterized in that it is composed of a stabilizer body 2 and an embedded part 3, the lower part of the embedded part 3 is located in the foundation concrete, and the stabilizer body 2 is fixedly connected with the foundation concrete according to the embedded part 3; the stabilizer Lifting piece body 2 is made up of back plate 2-1 and bottom attached plate 2-2, and back plate 2-1 is vertically fixedly connected with two angle plate bodies 2-1-2 by straight plate body 2-1-2, and its The cross-section is U-shaped, and the inner side of the bottom of the backboard 2-1 is fixedly connected with the bottom attachment board 2-2, and the bottom attachment board 2-2 is perpendicular to the back board 2-1; the straight board body 2-1-1 has There are two tension bolt holes 2-4 and twenty-six nail holes 2-3 connected with the axial force bar 1, and there are embedded bolt grooves 2...

Embodiment 2

[0038] Embodiment 2: An axial force rod member stabilizer, characterized in that it is composed of a stabilizer body 2 and an embedded part 3, the lower part of the embedded part 3 is located in the foundation concrete, and the stabilizer body 2 is in accordance with the preset The embedded part 3 is fixedly connected with the foundation concrete; the stabilizer body 2 is composed of a back plate 2-1 and a bottom attached plate 2-2, and the back plate 2-1 is composed of a straight plate body 2-1-1 and two corner plates The body 2-1-2 is vertically fixedly connected to each other, and its cross-section is U-shaped, and the inner side of the bottom of the backboard 2-1 is fixedly connected with the bottom attachment board 2-2, and the bottom attachment board 2-2 is perpendicular to the back board 2-1 ; There are four tension bolt holes 2-4 and thirty nail holes 2-3 connected with the axial force bar 1 on the straight plate body 2-1-1, and there is a pre-embedded on the bottom att...

Embodiment 3

[0053] Embodiment 3: An axial force rod member stabilizer, characterized in that it is composed of a stabilizer body 2 and an embedded part 3, the lower part of the embedded part 3 is located in the foundation concrete, and the stabilizer body 2 is in accordance with the preset The embedded part 3 is fixedly connected with the foundation concrete; the stabilizer body 2 is composed of a back plate 2-1 and a bottom attached plate 2-2, and the back plate 2-1 is composed of a straight plate body 2-1-1 and two corner plates The body 2-1-2 is vertically fixedly connected to each other, and its cross-section is U-shaped, and the inner side of the bottom of the backboard 2-1 is fixedly connected with the bottom attachment board 2-2, and the bottom attachment board 2-2 is perpendicular to the back board 2-1 ; There are six tension bolt holes 2-4 and twenty nail holes 2-3 connected with the axial force bar 1 on the straight plate body 2-1-1, and there are embedded bolt holes 2-3 on the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com