Downhole continuous wave mud pulse generator

A technology of mud pulse and generator, which is applied in wellbore/well components, measurement, earthwork drilling and production, etc. It can solve the problems of drilling speed instrument disconnection, inability to balance downhole pressure, and unsalvageable instrument, etc., and achieves a wide range of applications , avoid electrical virtual connection, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

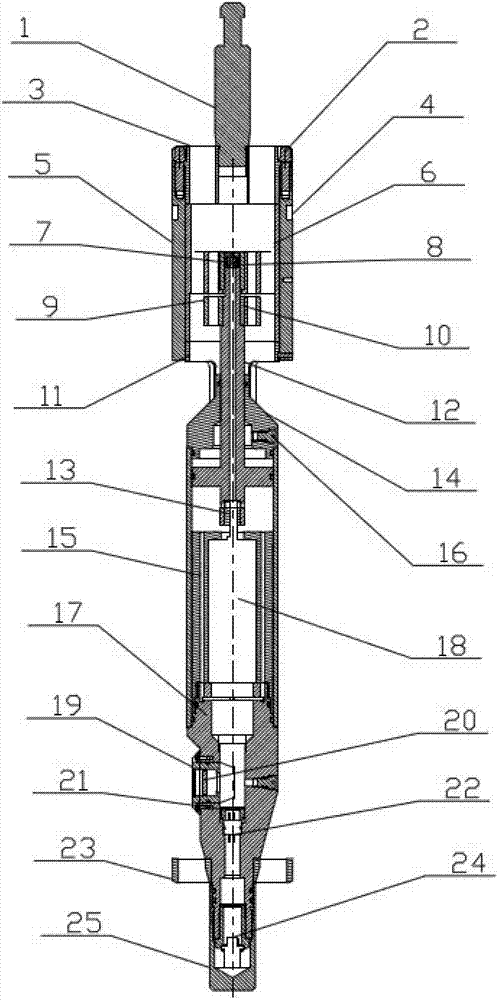

[0019] Such as figure 1 As shown, the present invention provides a downhole continuous wave mud pulse generator, the downhole continuous wave mud pulse generator includes a continuous wave pulse generating assembly and a driving assembly for driving the continuous wave generating assembly to work; the continuous wave pulse generating assembly includes The casing 5, the stator 6 arranged inside the casing 5 from top to bottom, and the rotor 9 that can rotate axially around the axial direction of the casing 5 and move axially around the axial direction of the casing 5; the stator 6 and the rotor 9 And along the axial direction of the casing 5, there are mud flow holes; the upper end of the casing 5 is provided with an end cover 3; the end cover 3 is provided with a through hole for the passage of mud; The through holes on the rotor 9 communicate with each other; the flow holes on the rotor 9 communicate with the opening of the casing 5; the drive assembly drives the rotor 9 to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com