A method of coal mining and gangue filling

A technology for gangue and coal shearer, which is applied in the fields of backfill, mining equipment, earthwork drilling, etc., can solve the problems affecting coal mining construction method and backfill construction method, low efficiency, etc., achieves good roof support effect, and reduces pull frame time, the effect of improving coal mining efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

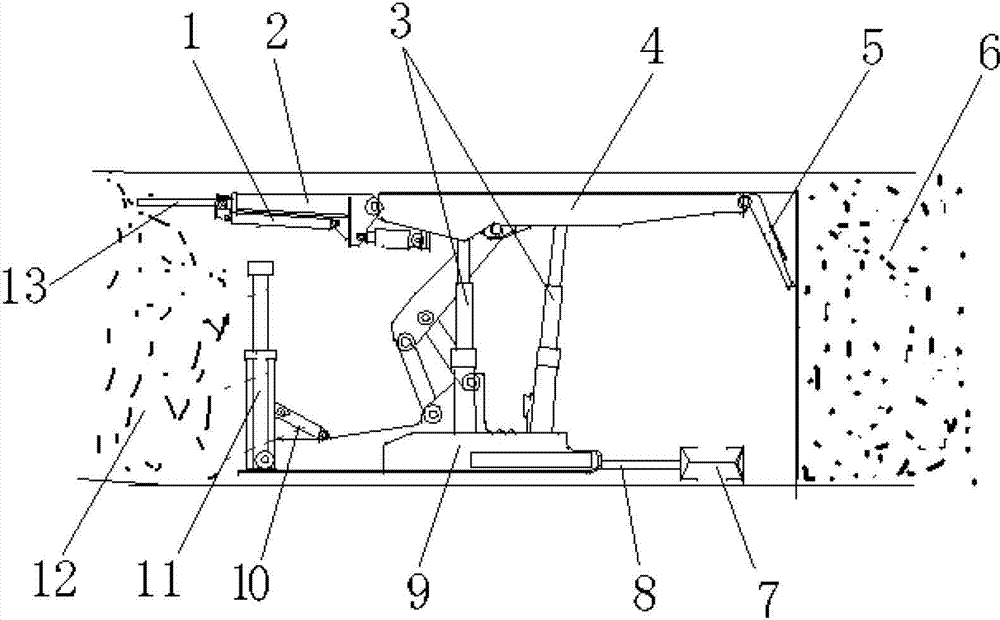

[0014] Embodiments are further described below with reference to the accompanying drawings.

[0015] One is to improve the existing filling bracket:

[0016] from figure 1 It can be seen that the filling bracket used for filling in the present invention is made up of base 9, hydraulic column 3, top beam 4, front swing beam 5, rear tail beam 2 and hydraulic pushing rod 8, and the hydraulic pushing rod 8 is designed to be 1.2 meters. The telescopic beam 13 is added on the rear tail beam 2, and the telescopic beam 13 is moved by the telescopic hydraulic cylinder 1, and the pushing stroke is 800 mm. A telescopic baffle 11 is installed at the rear of the base 9 of the filling bracket, and the baffle 11 is hinged with the base 9. , it can swing back and forth through the swing hydraulic cylinder 10, with a swing angle of ±12°;

[0017] The second is that when the coal shearer cuts the coal seam 6, it cuts coal in two directions along the top and bottom plates, enters two knives at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com