Cooling fan for engine, cooling system for engine and engineering machinery

A technology for engine cooling and engineering machinery, which is applied in the direction of engine cooling, engine components, machine/engine, etc. It can solve the difficulties in matching design and practical application of cooling systems, weaken the exhaust capacity of cooling fans, and reduce the heat dissipation capacity of the cooling system of the whole machine and other problems, to achieve the effect of small space occupation, simple structure, and avoiding the dead angle of supplementary air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

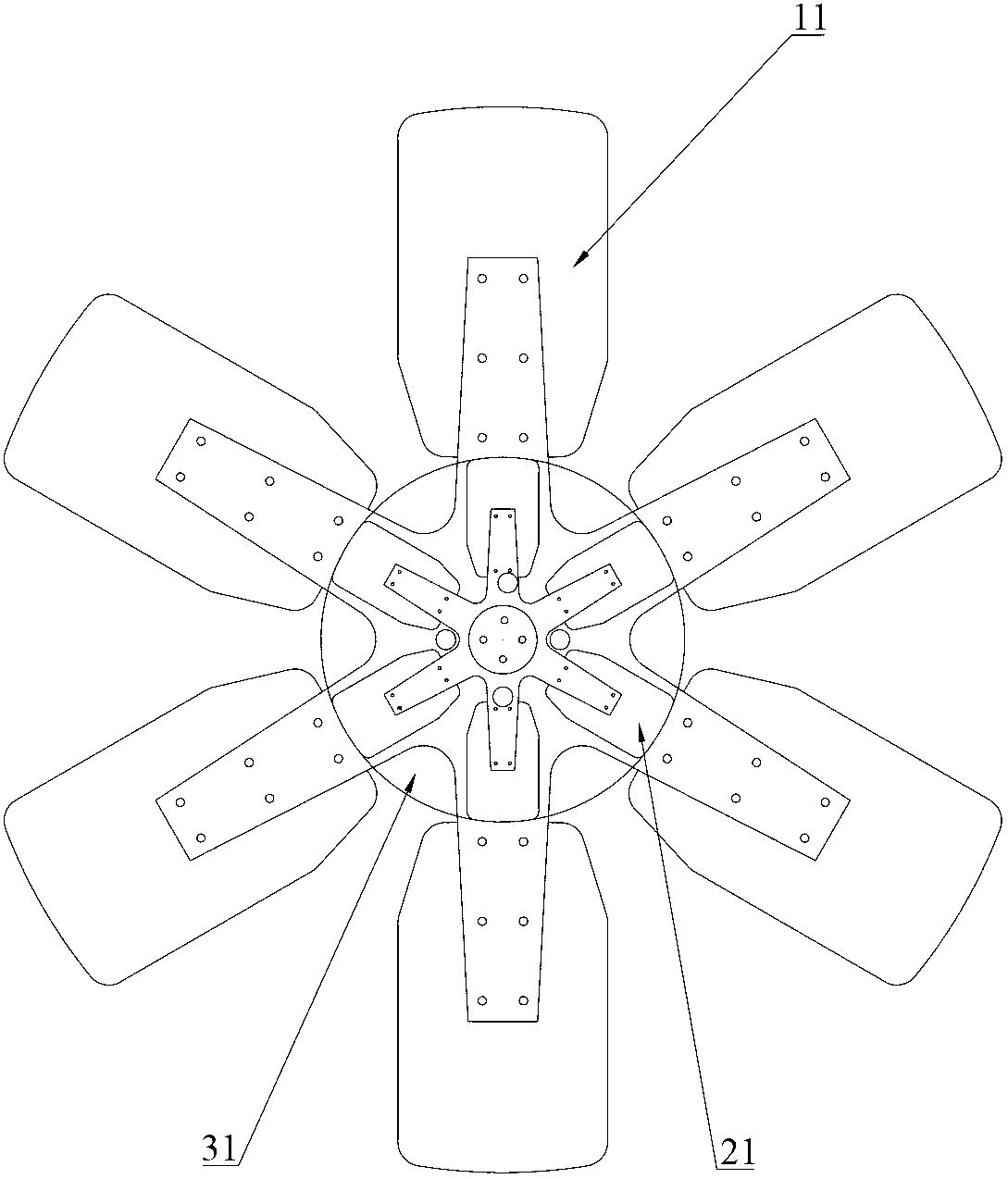

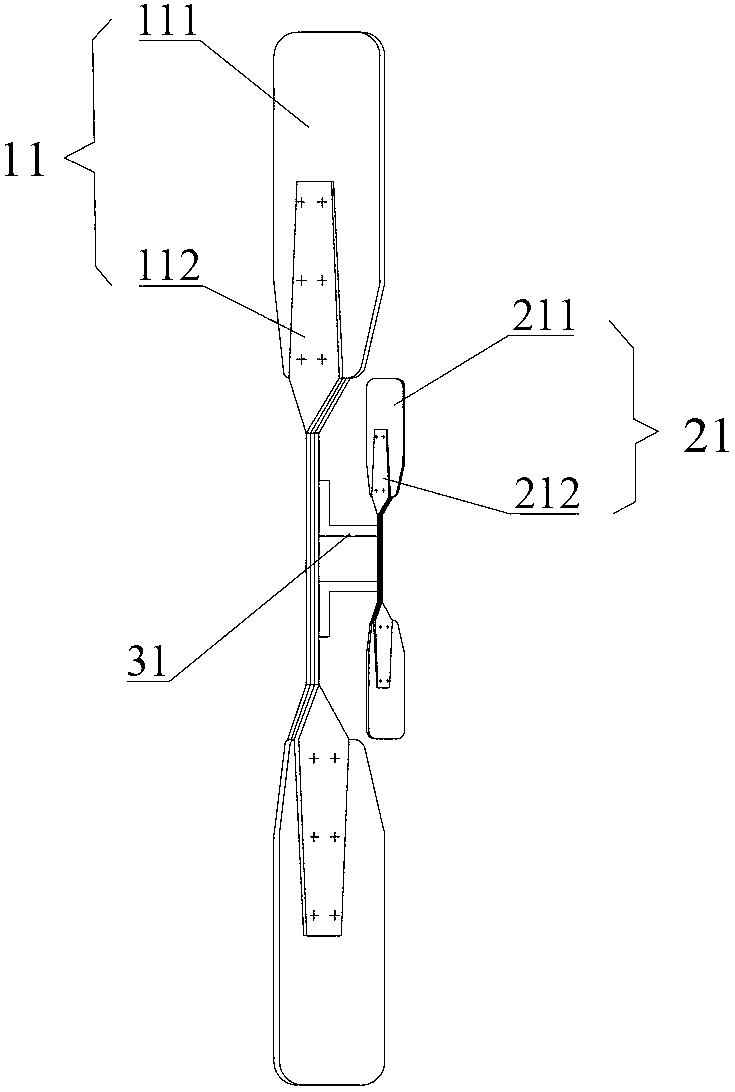

[0026] The basic idea of the present invention is to increase the exhaust air volume in the low wind area of the cooling fan by adding small fan blades along the axial direction of the hub, thereby optimizing the air exhaust performance of the cooling fan.

[0027] The preferred embodiments of the present invention will be further described below in conjunction with the accompanying drawings. It should be noted that the tail end of the present invention refers to the end of the two ends of the component that is close to the hub. Correspondingly, the tail refers to the end of the component that is close to the hub. The head end refers to the end opposite to the tail end.

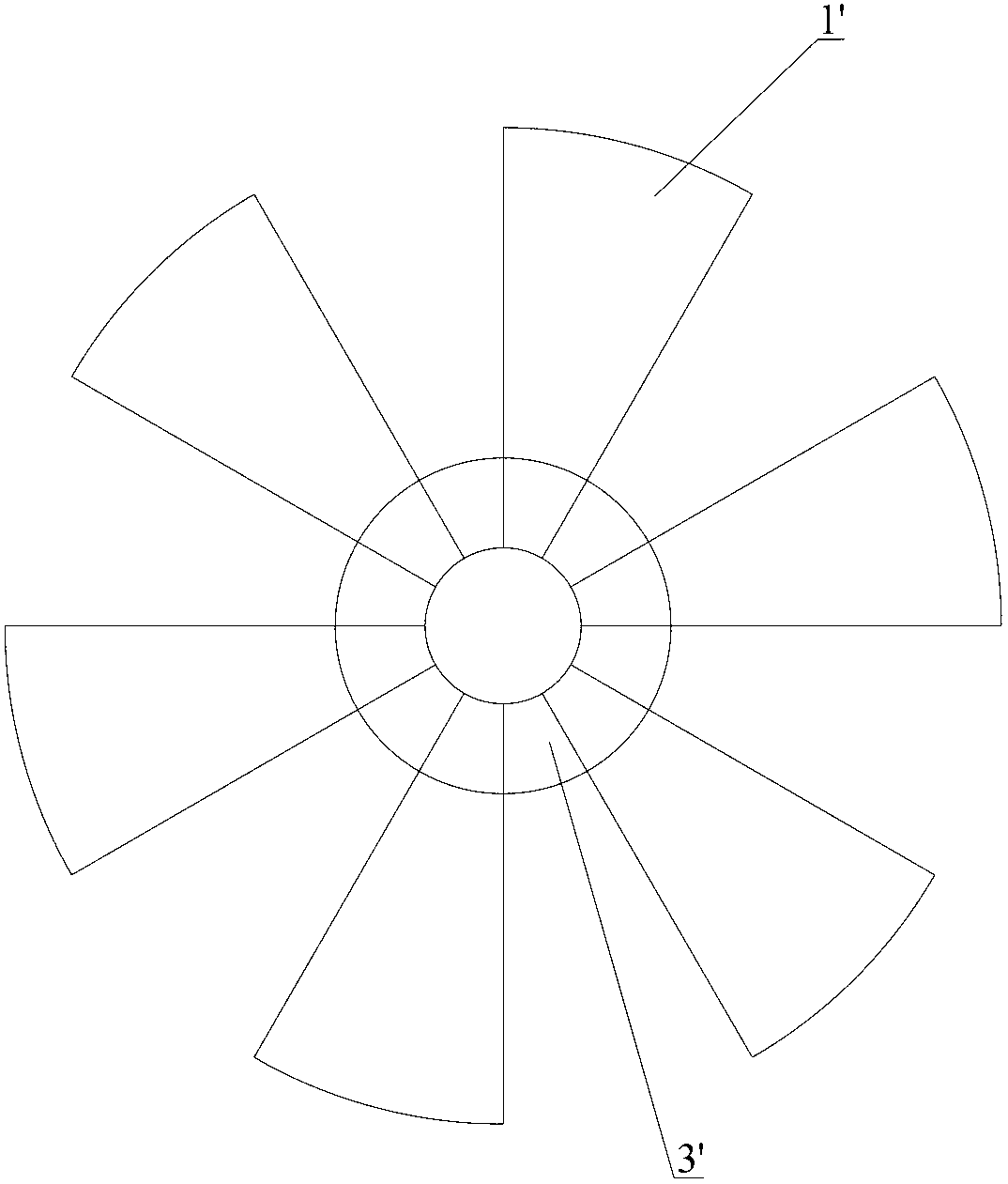

[0028] figure 2 and image 3 The structure of the engine cooling fan provided by Embodiment 1 of the present invention is shown, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com