Fuel pressure stabilizer and fuel jetting device thereof

A fuel pressure and stabilizer technology, which is applied to fuel injection devices, charging systems, machines/engines, etc., can solve the problems of unsatisfactory accuracy and stability of fuel supply pressure, and achieve stability and stability. effect with precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with examples, but the embodiments of the present invention are not limited thereto.

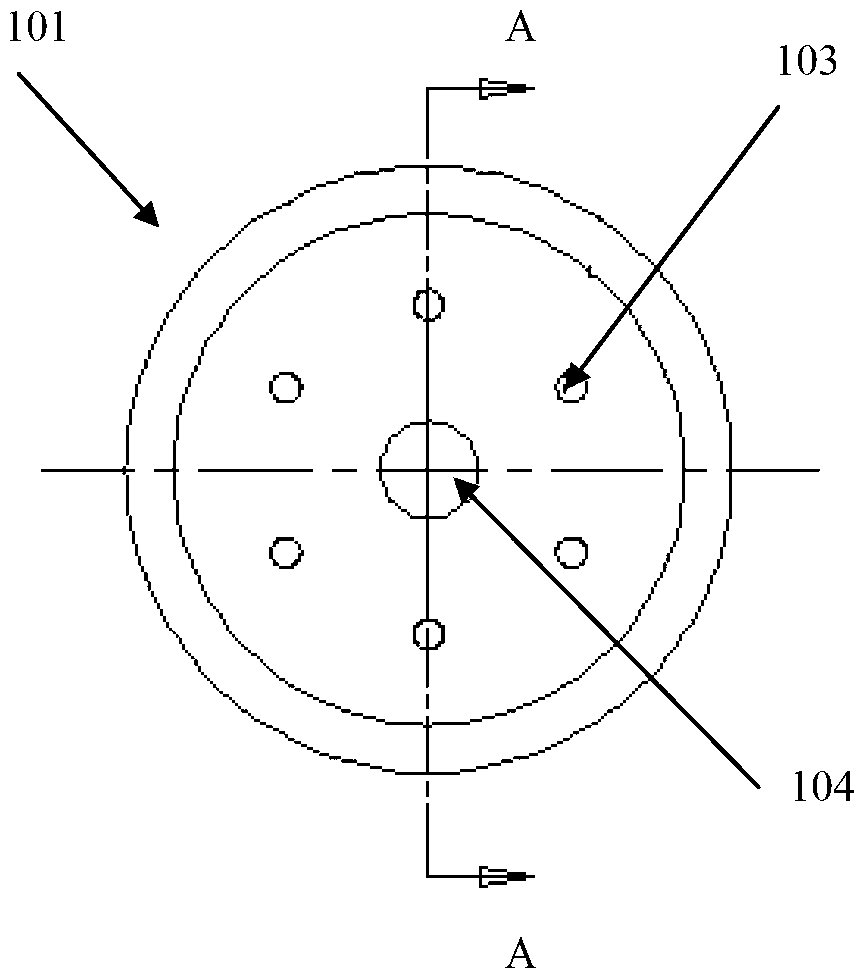

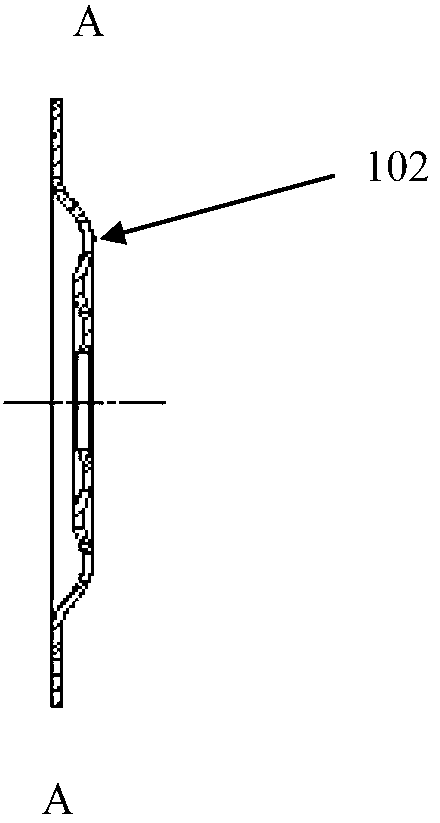

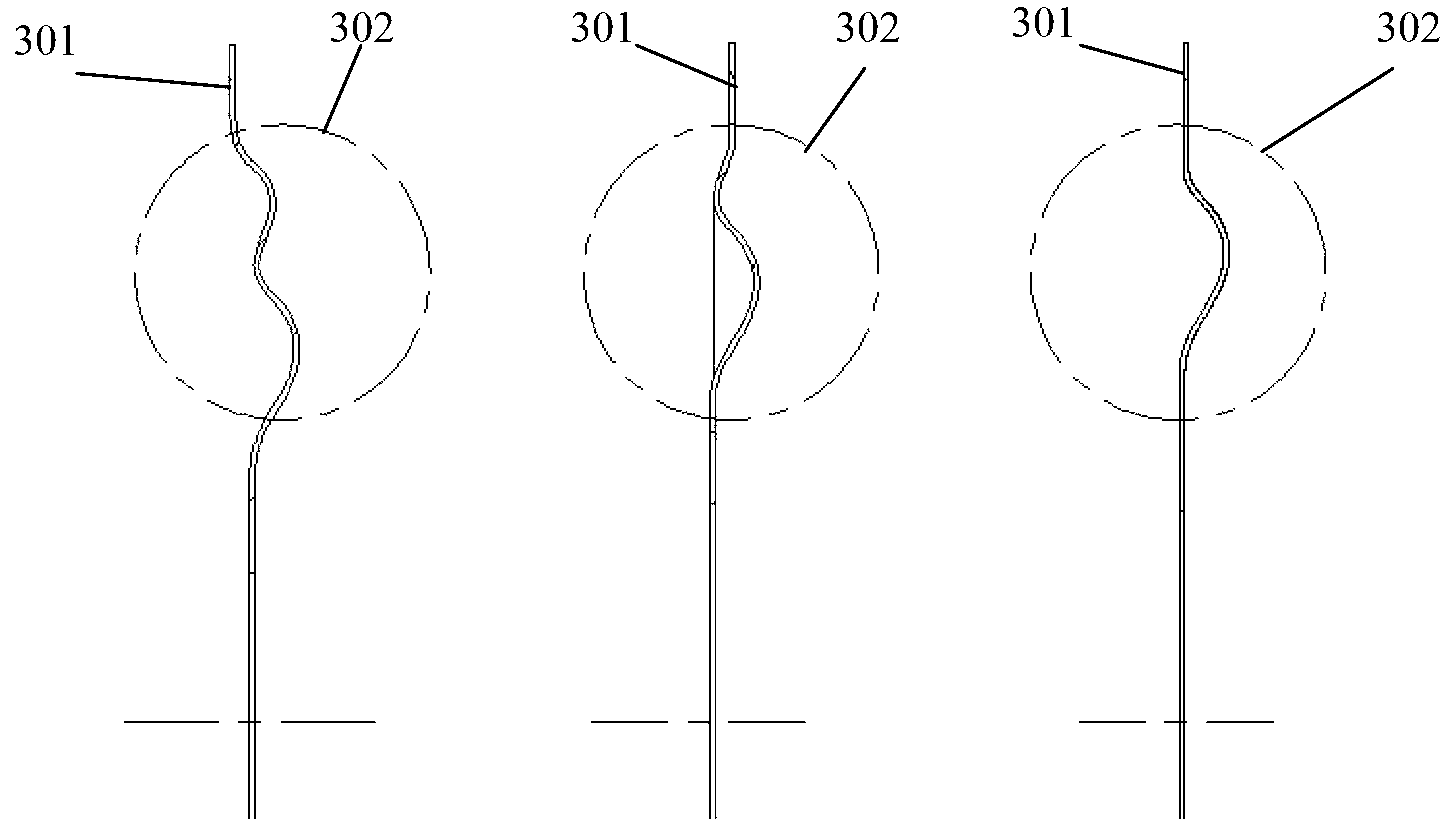

[0040] figure 1 A schematic structural diagram of a fuel pressure stabilizer according to an embodiment of the present invention is shown. figure 2 show figure 1 A schematic diagram of the cross-sectional structure shown in A-A. refer to figure 1 or figure 2 An embodiment of a fuel pressure stabilizer is shown, which includes a stabilizer body 101 on which an elastic structural part 102 for pressure adjustment through expansion or contraction is arranged. Through the elastic structure part 102, the fuel dynamic pressure changes and fluctuations on the inside and outside of the stabilizer body 101 can be expanded or stretched accordingly, thereby changing the volume of the fuel volume chamber, so as to realize the stability of the fuel pressure in the pressure chamber. .

[0041] In order to make ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com