Device for converting kinetic energy of liquid into mechanical energy

A kinetic energy conversion and mechanical energy technology, applied in mechanical equipment, machines/engines, circulating chain machinery, etc., can solve the problems of converting kinetic energy of water flow into mechanical energy, difficulties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

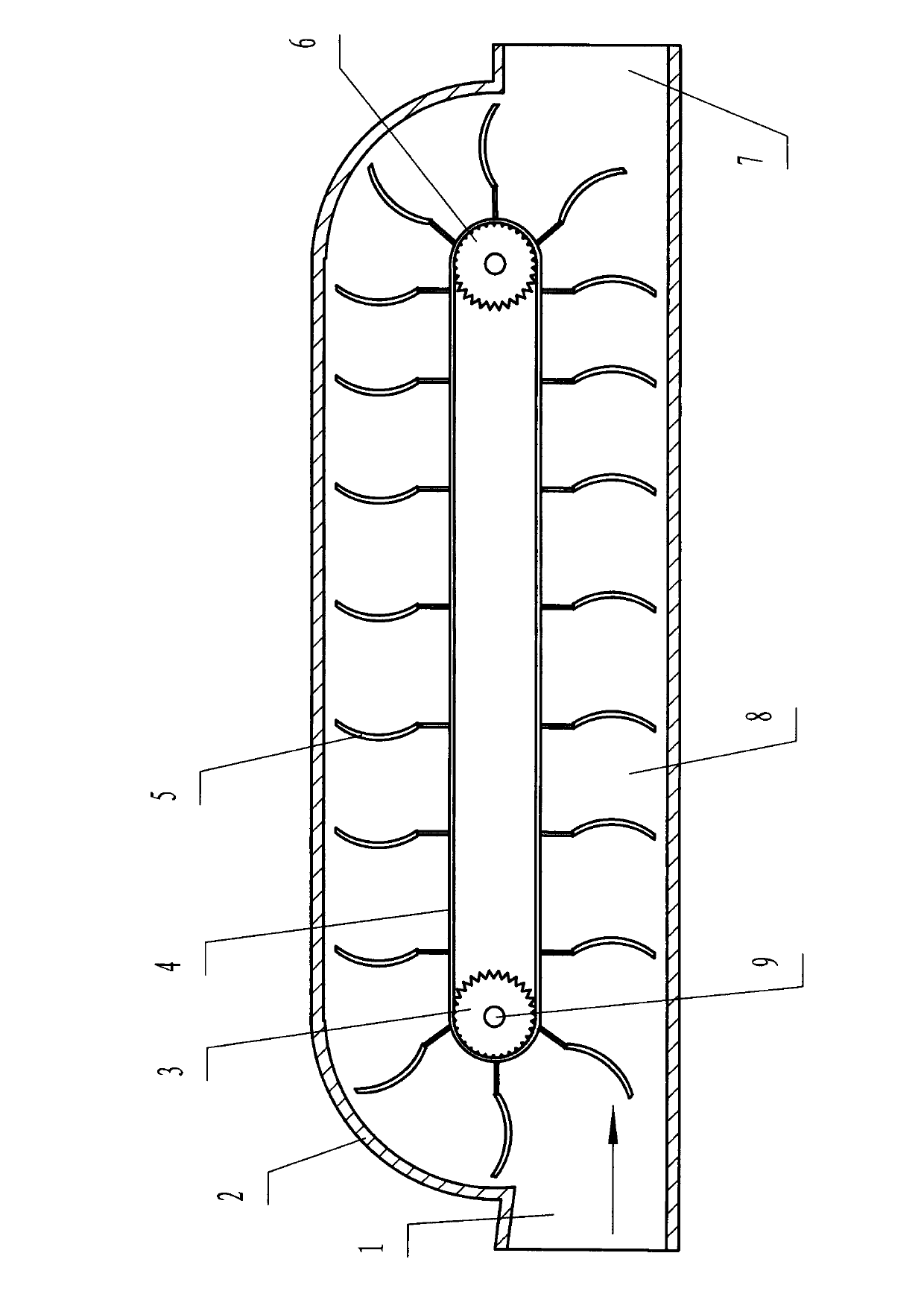

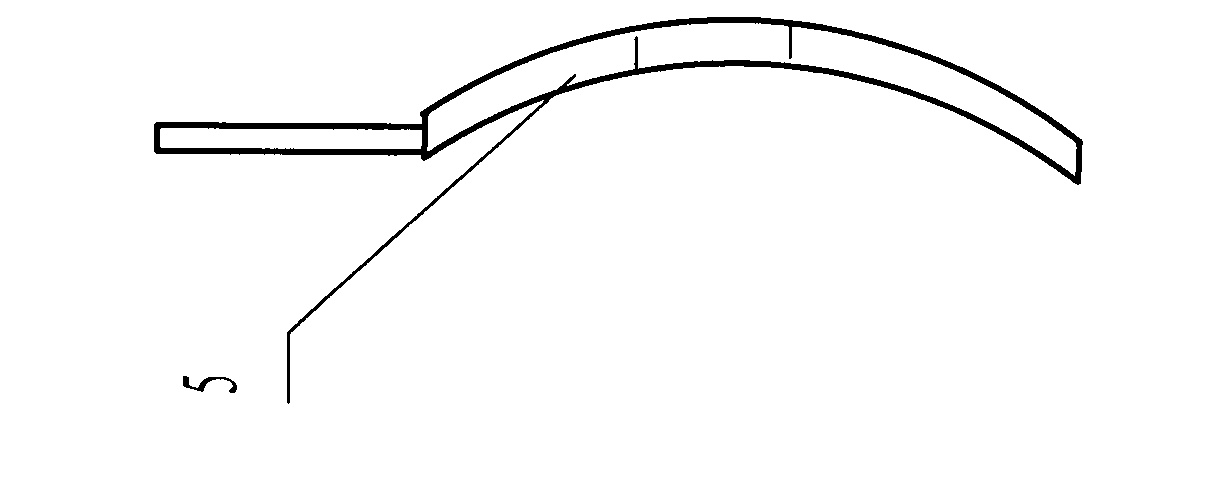

[0015] Embodiment 1: with reference to attached Figure 1~3 , including a housing 2, the housing 2 is "tank crawler-shaped", one end of the housing 2 is provided with a liquid inlet 1, the other end of the housing 2 is provided with a liquid outlet 7, and the housing 2 is provided with a flow channel 9 and a liquid driving device, the liquid driving device is composed of a driving wheel 3, a power output shaft 8, a driven wheel 6, a transmission chain belt 4, and a vane 5, and the driving wheel 3 is located at the liquid inlet 1, The power output shaft 8 is arranged on the driving wheel 3 shaft, the driven wheel 6 is arranged at the liquid outlet 7, the driving wheel 3 is provided with transmission gear teeth, and the transmission chain belt 4 is arranged on the driving wheel 3 and the driven wheel 6 , the transmission gear teeth on the driving wheel 3 mesh with the transmission chain belt 4, and the driven wheel 6 is a smooth runner, so that the transmission chain belt 4 can ...

Embodiment 2

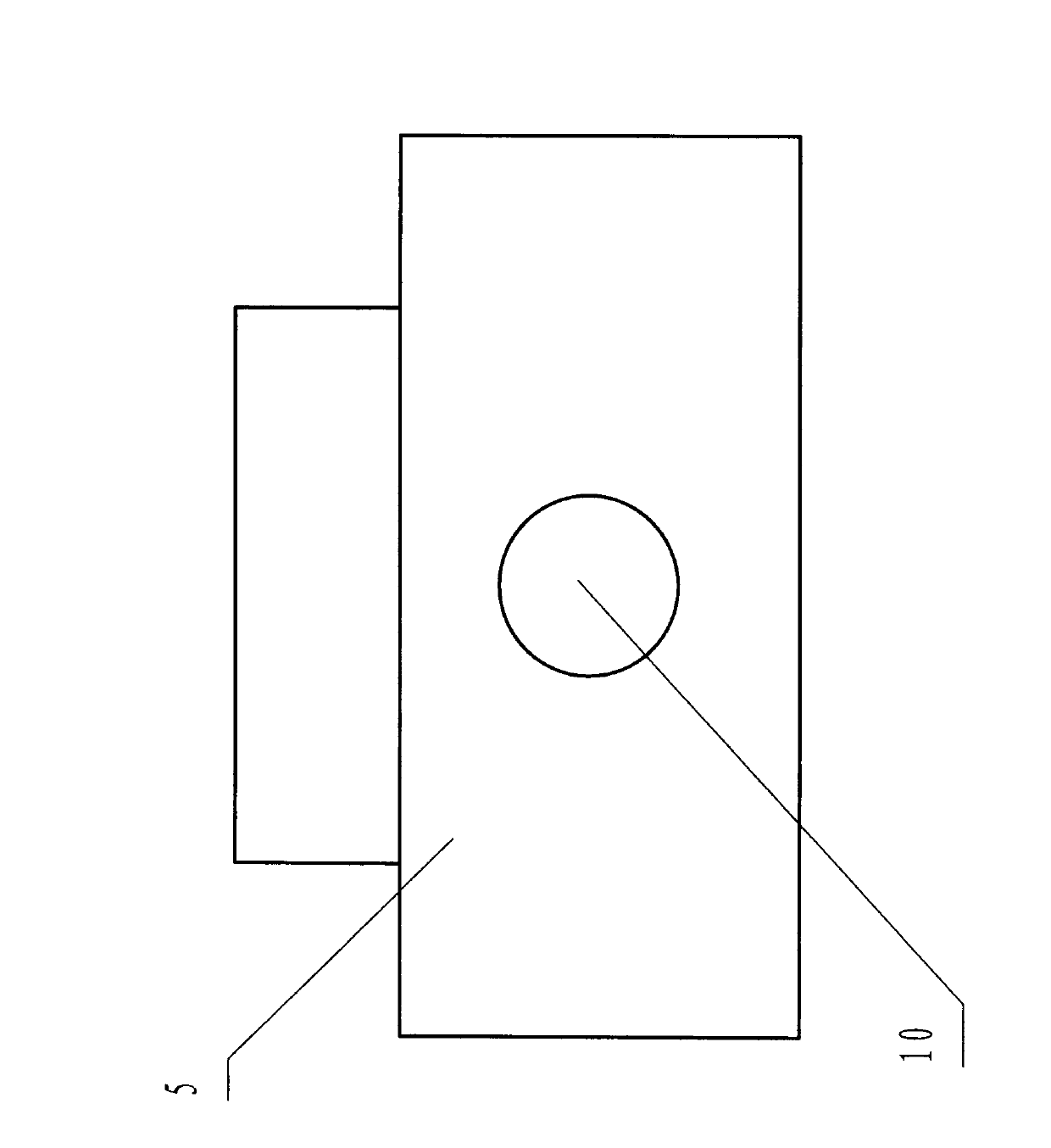

[0016] Embodiment 2: Compared with Embodiment 1, the difference lies in that the area of the said perforation 10 accounts for 22% of the surface area of the blade, and two are provided.

Embodiment 3

[0017] Embodiment 3: Compared with Embodiment 1, the difference is that the area of the said perforation 10 accounts for 30% of the surface area of the blade, and three are provided.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com