Pressure retaining valve with automatic water-drain pollution-discharge function

A technology of automatic drainage and pressure maintaining valves, applied in the direction of functional valves, safety valves, balance valves, etc., can solve the problems of unguaranteed water discharge efficiency, affecting the performance of the valve body assembly, hidden dangers of system reliability, etc., and achieve structural Simple, convenient maintenance and replacement, eliminating the effect of manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with the arrangement of the technical solutions shown in the accompanying drawings, the present invention will be further described in detail, but the present invention is not limited to the arrangement of the technical solutions:

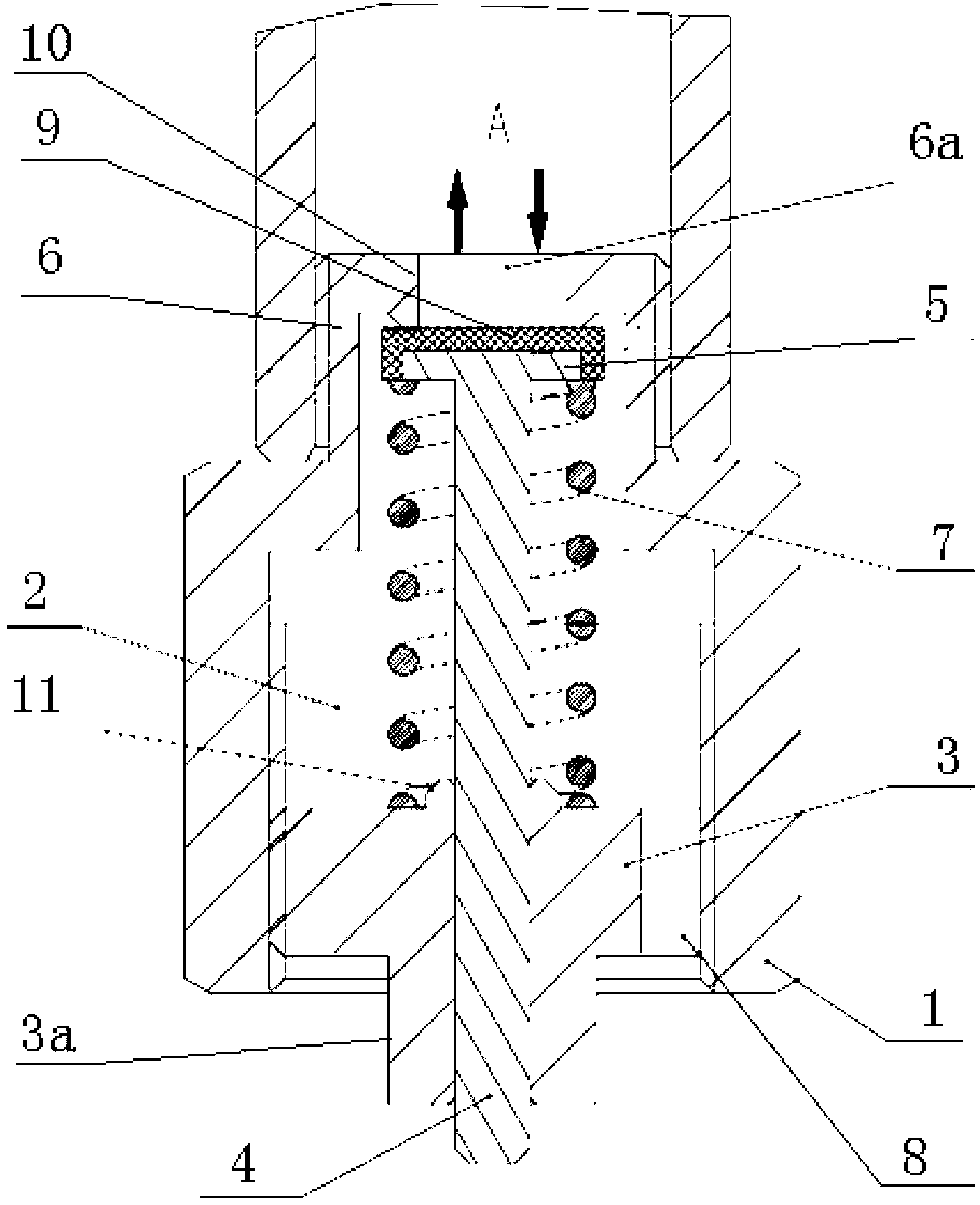

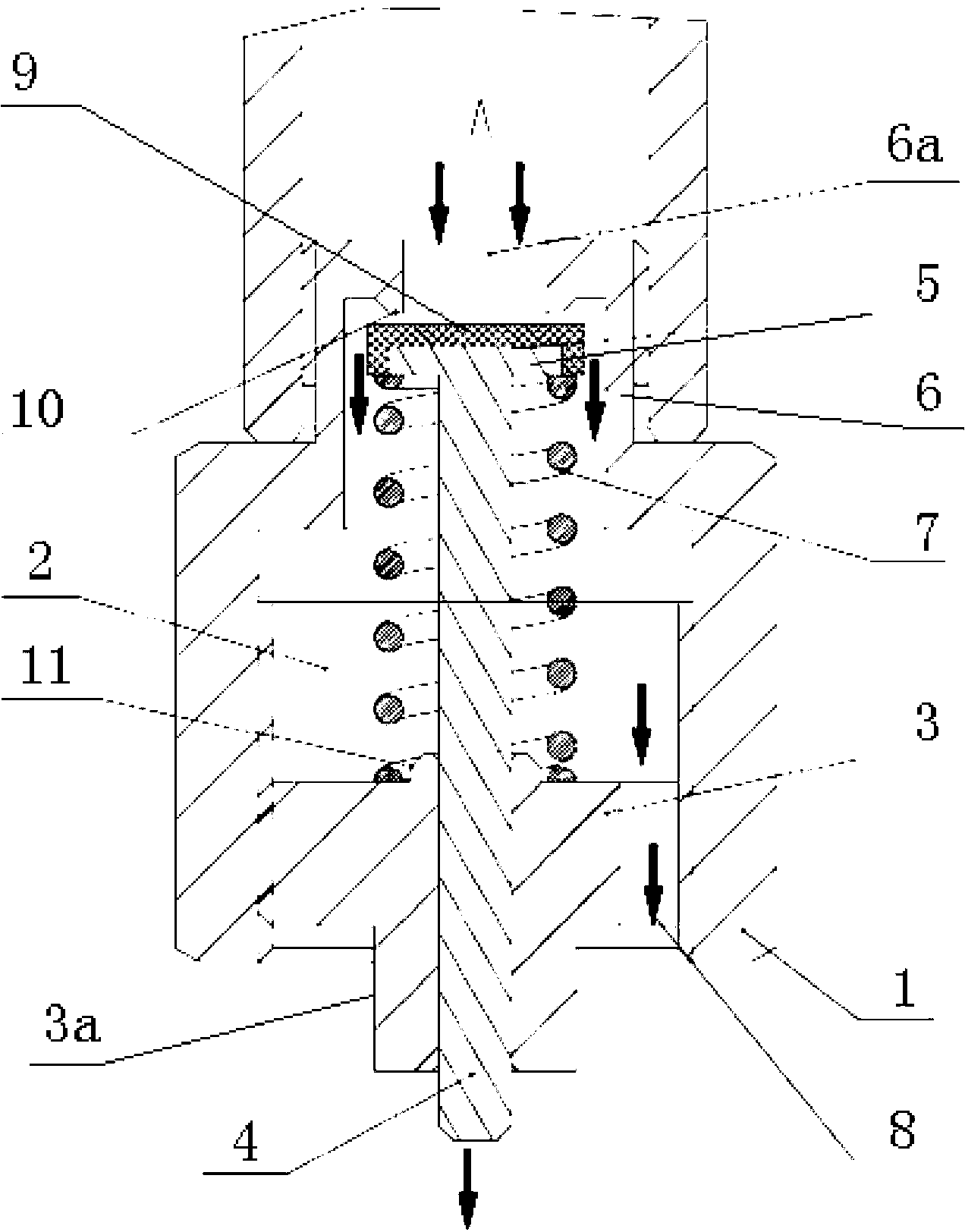

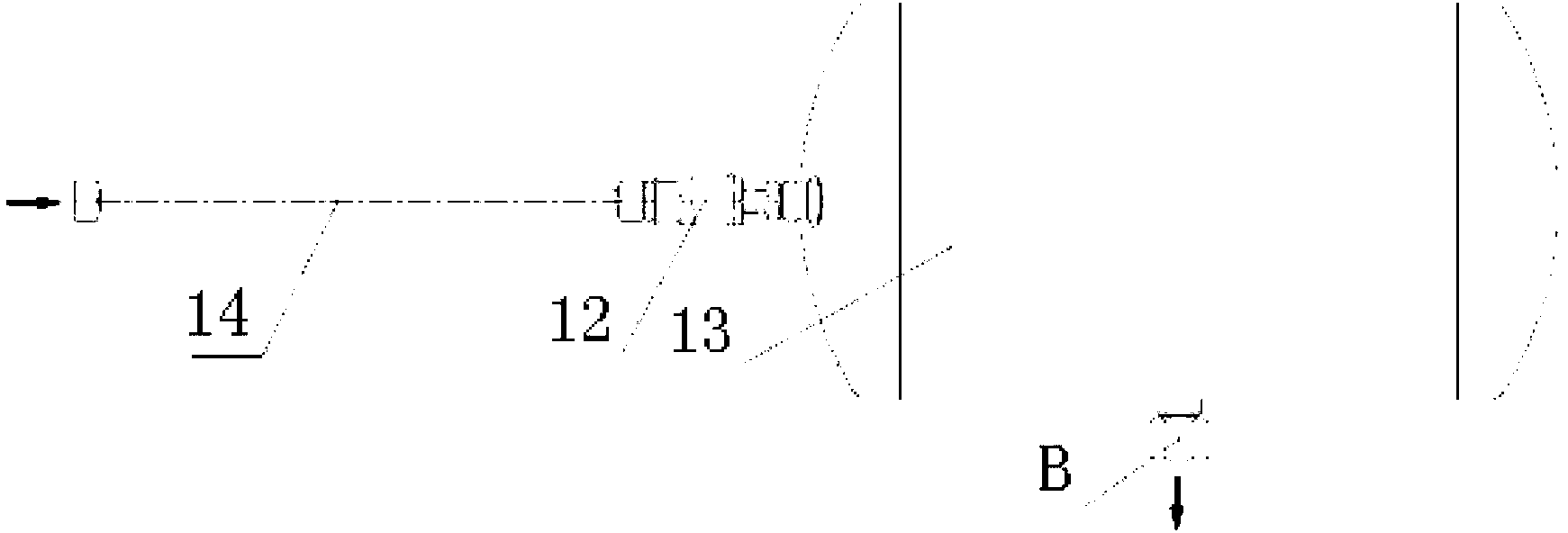

[0014] figure 1 , figure 2 It is a schematic cross-sectional structure diagram of the present invention: the pressure maintaining valve with automatic drainage and sewage discharge function of the present invention includes a valve body 1, a valve cavity 2, a plug 3 at the bottom of the valve body 1, a valve stem 4, and the top of the valve cavity is an inlet connector 6. There is an end seal 10 between the inlet 6a and the wall of the inlet connector 6, and the inlet 6a communicates with the valve cavity 2; the lower end of the valve stem 4 passes through the guide hole in the center of the plug 3, and the upper end of the valve stem 4 is a sealing disc 5 , the sealing disc 5 corresponds to the inlet 6a, the sealing d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com