Multi-actuating travel and return travel irregularly-shaped wheel lubricating grease delivery device

A technology of conveying device and special-shaped wheel, applied in the direction of lubrication pump, engine lubrication, engine components, etc., can solve the problems of large flow unevenness of reciprocating pump, unable to realize stable transmission of grease, etc., achieve simple structure, reduce impact, The effect of improving conveying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

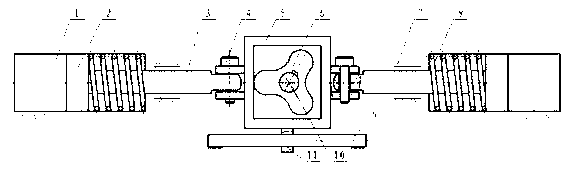

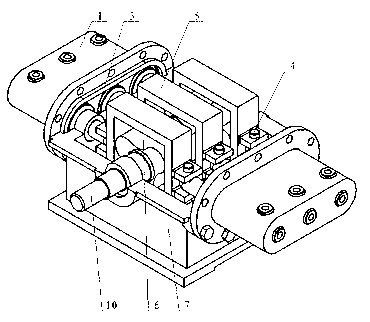

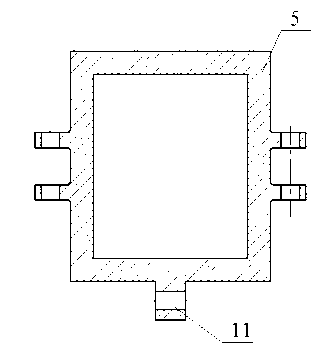

[0015] like figure 1 As shown, the multi-push backstroke special-shaped wheel grease delivery device of the present invention mainly consists of piston cylinder 1, piston 2, piston rod 3, cylindrical pin with cap 4, frame 5, special-shaped wheel 6, square frame 7, reset Spring 8, fixed shaft 9, input shaft 10 constitute, input shaft 10 is located at the middle part of the frame 7 that is square, is provided with a plurality of special-shaped wheels 6 equidistantly on the input shaft 10, and the outside of each special-shaped wheel 6 is provided with A frame 5 fixed on the frame 7, a piston cylinder 1 is symmetrically arranged on the frame 7 on the left and right sides of each frame 5, and the end of the piston rod 3 matched with the piston cylinder 1 is passed through a cylindrical pin 4 with a cap. It is fixed on the side of the frame 5; the bottom of eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com