LED (Light Emitting Diode) warning lamp

An LED warning light, one-sided technology, applied in the field of LED lighting, can solve the problems of increased cost of warning light manufacturing, difficult applicability of the reflector, and insufficient uniformity of light output, so as to achieve a simple and clear production process, convenient assembly, and light efficiency utilization. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

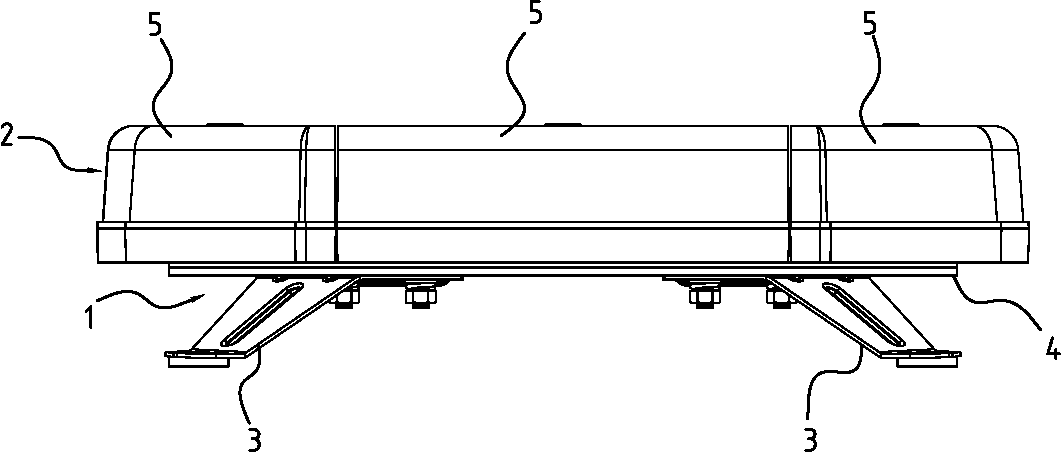

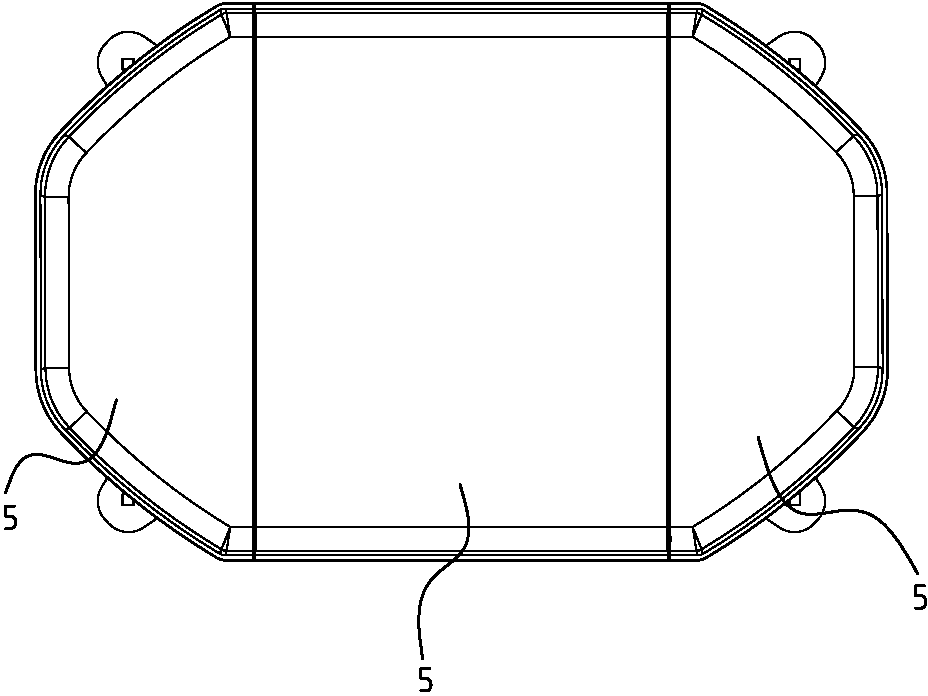

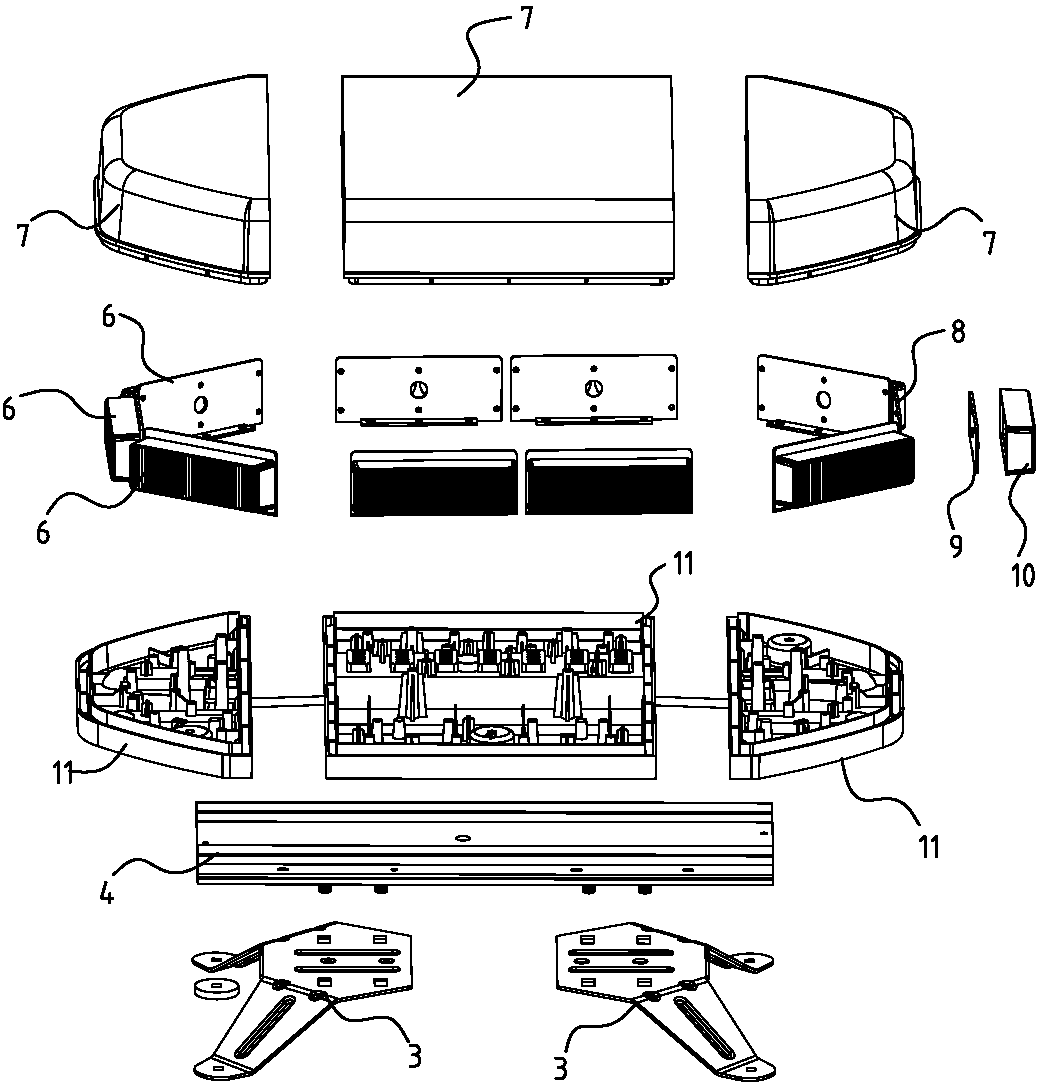

[0019] Such as Figures 1 to 3 As shown, an LED warning light includes a base 1 and a light-emitting assembly 2 arranged on the base 1 . The light-emitting assembly 2 is composed of three light-emitting units 5 , which are the middle light-emitting unit 5 and the end light-emitting units 5 located on both sides of the middle light-emitting unit 5 . The adjacent light-emitting units 5 are connected in series by plugging, so that the electrical connection between the light-emitting units 5 is more convenient. The light-emitting unit 5 includes an optical module 6, a lamp holder 11 and a mask 7 matched with the lamp holder 11, the optical module 6 is fixed on the lamp holder 11 by a fixing bracket 8, and the light emitting of the optical module 6 face outward. Such as image 3 As shown, the base 1 includes a strip-shaped connecting bracket 4 and mounting frames 3 located at both ends of the bottom of the connecting frame 4; the mounting frame 3 is used to support the entire wa...

Embodiment 2

[0022] The difference from that described in Example 1 is that the radius of curvature of the arc-shaped protrusion 21 shown is 0.2-2.0mm; the angle θ1 between one side of the first triangular protrusion 17 and the horizontal line is 36°, and the other side is between the horizontal line and the horizontal line. The angle θ2 is 5.7°; the included angle θ3 between one side of the second triangular protrusion 18 and the horizontal line is 35°, and the included angle θ4 between the other side and the horizontal line is 4°; the included angle θ5 between one side of the third triangular protrusion 19 and the horizontal line The included angle θ6 between the other side and the horizontal line is 4.75°; the included angle θ7 between one side of the fourth triangular protrusion 20 and the horizontal line is 30°, and the included angle θ8 between the other side and the horizontal line is 6.85°.

Embodiment 3

[0024] The radius of curvature of the arc-shaped protrusion 21 shown is 0.2~2.0mm; the angle θ1 between one side of the first triangular protrusion 17 and the horizontal line is 30°, and the angle θ2 between the other side and the horizontal line is 3°; the second triangular protrusion 17 The included angle θ3 between one side of the raised 18 and the horizontal line is 28°, the included angle θ4 between the other side and the horizontal line is 2°; The angle θ6 is 4°; the angle θ7 between one side of the fourth triangular protrusion 20 and the horizontal line is 25°, and the angle θ8 between the other side and the horizontal line is 5°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com