Automatic control system of smoke oven

An automatic control system and flue gas technology, applied in the field of automatic control of ovens, can solve the problems of difficult quality assurance of boiler ovens, low adjustment accuracy, temperature deviation, etc., achieve good economic and social benefits, reduce manual use, reduce The effect of the number of overhauls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

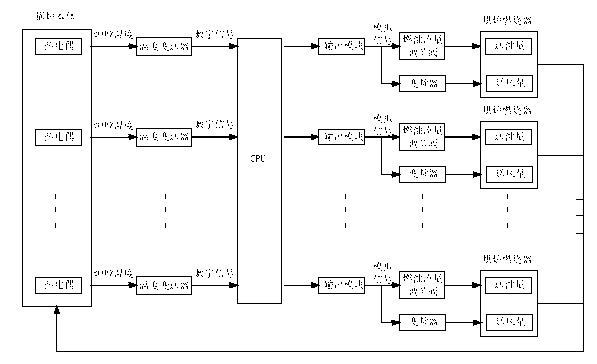

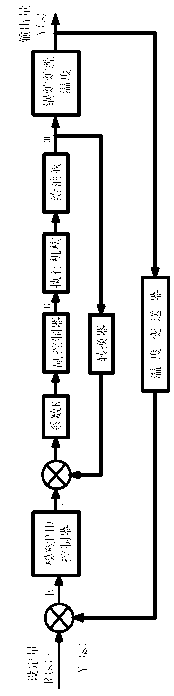

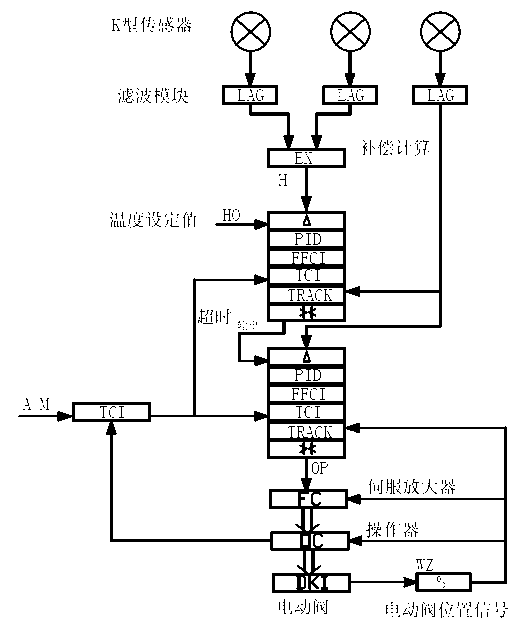

[0021] This system adopts the PID control program with fuzzy self-tuning, when the cycle of digital control is infinitely small, it is close to continuous control. Embed the control algorithm of fuzzy PID into the design of PLC, and optimize the selection of input and output components, electrical protection devices, alarm and display components: the programmable controller host CPU module uses XC3-24R-E type, the analog The output module is XC-E2DA, the digital display instrument is a 7-inch TH765-N touch control display screen, and the temperature sensor is a K-type armored thermocouple.

[0022] The fuzzy PID controller is designed for the control characteristics of the furnace temperature, and the control of the furnace temperature is mainly realized by adjusting the oil supply of the valve. At the same time, in order to avoid the frequent action of the furnace temperature regulator. When the furnace temperature changes little, the furnace temperature deviation does not p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com