Drying method of mask after cleaning

A drying method and mask technology, applied in the direction of drying solid materials, drying solid materials without heating, drying, etc., can solve problems such as secondary pollution of MASK, and achieve the effect of avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

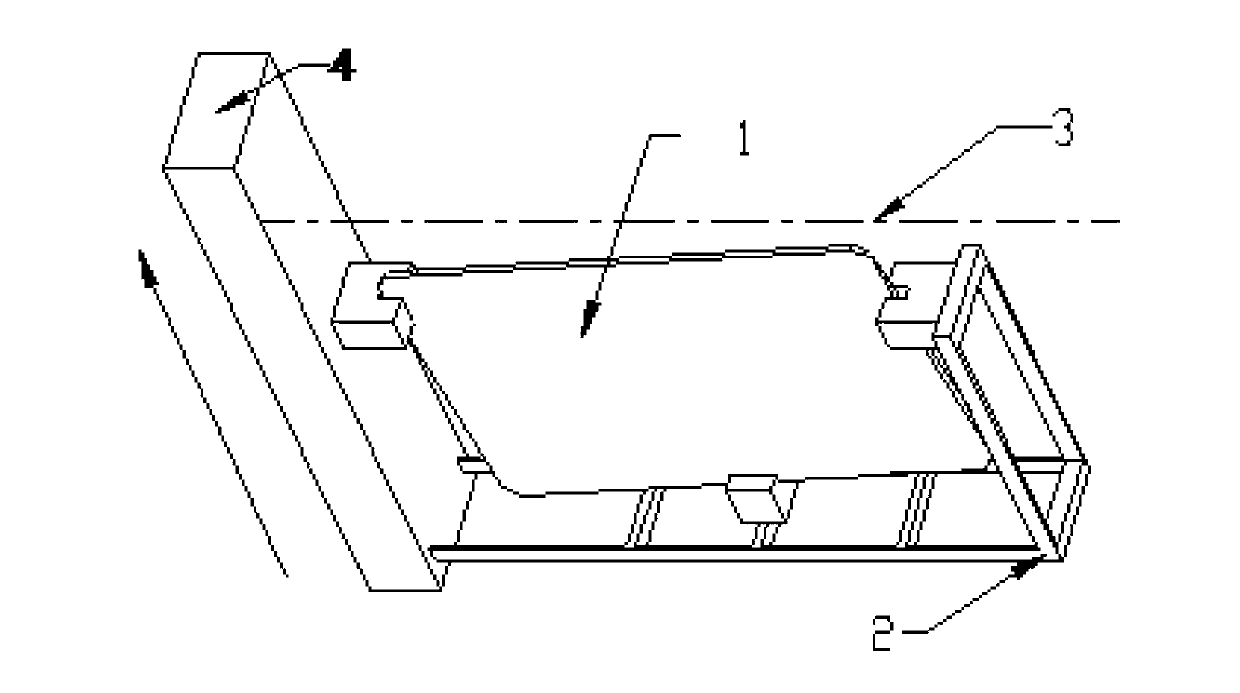

[0008] Such as figure 1 As shown, the present invention is a method for drying a mask after cleaning, comprising the following steps: fixing the cleaned mask 1 on a jig 2 and fully immersing it in pure water, the jig 2 and the slow moving device 4 Connect so that the fixture 2 and the mask plate 1 can be lifted slowly and steadily to leave the water surface 3, and the lifting speed is controlled at 10-70mm / min to lift at a constant speed until the mask plate 1 is completely separated from the pure water surface 3, for example, by Lift at a constant speed of 50mm / min.

[0009] Wherein the mask 1 is rectangular, the plane where the mask 1 is located is perpendicular to the water surface 3 of pure water, and the straight line where the long side of the mask 1 is located obliquely intersects with the water surface 3 of pure water at an angle of 10-30 degrees.

[0010] It has been proved by experiments that when the lifting speed of the mask plate 1 is 10-70 mm / min, the pure water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com