Carbon calcining rotary kiln

A rotary kiln and calcination technology, applied in the field of rotary kiln, can solve problems such as unreasonable installation of secondary and tertiary air ducts, poor physical and chemical indicators, and backward movement of the calcination zone, so as to solve large energy consumption, improve product quality, and improve physical and chemical The effect of indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited by the embodiments.

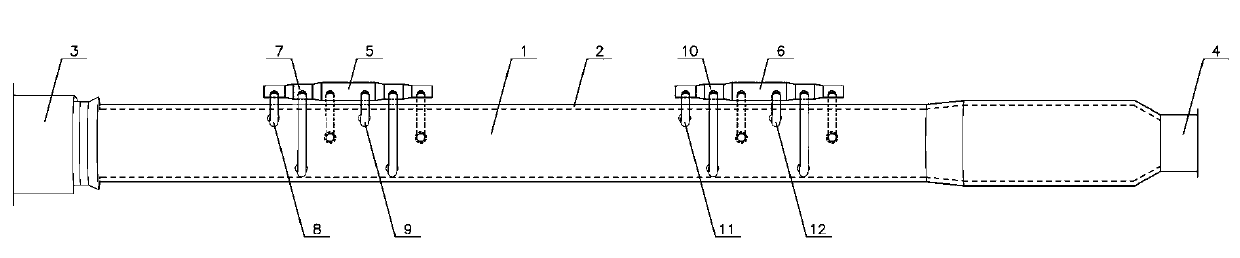

[0015] Such as figure 1 As shown, a carbon calcining rotary kiln of the present invention includes a kiln body 1, a lining 2, a kiln head 3, a kiln tail 4, a secondary air supply system 5, and a tertiary air supply system 6, wherein the secondary air supply system 5 It is composed of a secondary air blower 7, a front secondary air duct 8 and a rear secondary air duct 9, the front secondary air duct 8 and the rear secondary air duct 9 are composed of 3-6 air ducts, and the air ducts are Arranged equidistantly around the kiln body 1, the straight-line distance between adjacent air ducts is 1.2-1.5 meters, and the angle between adjacent air ducts is 60-120 degrees; the tertiary air supply system 6 is composed of tertiary air fans 10 1. The first three air ducts 11 an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com