Diameter measuring tool of inner spherical section circle and measuring method

A measurement method, a cross-sectional circle technology, applied in the direction of mechanical diameter measurement, etc., can solve the problems of long detection time, increased repeated positioning error, and the inability to realize the detection of positioning and tightening on the grinding machine, so as to achieve simple use and reduce repeated positioning effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

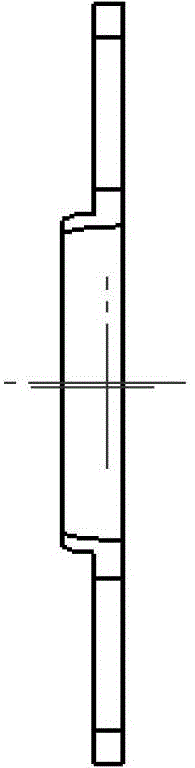

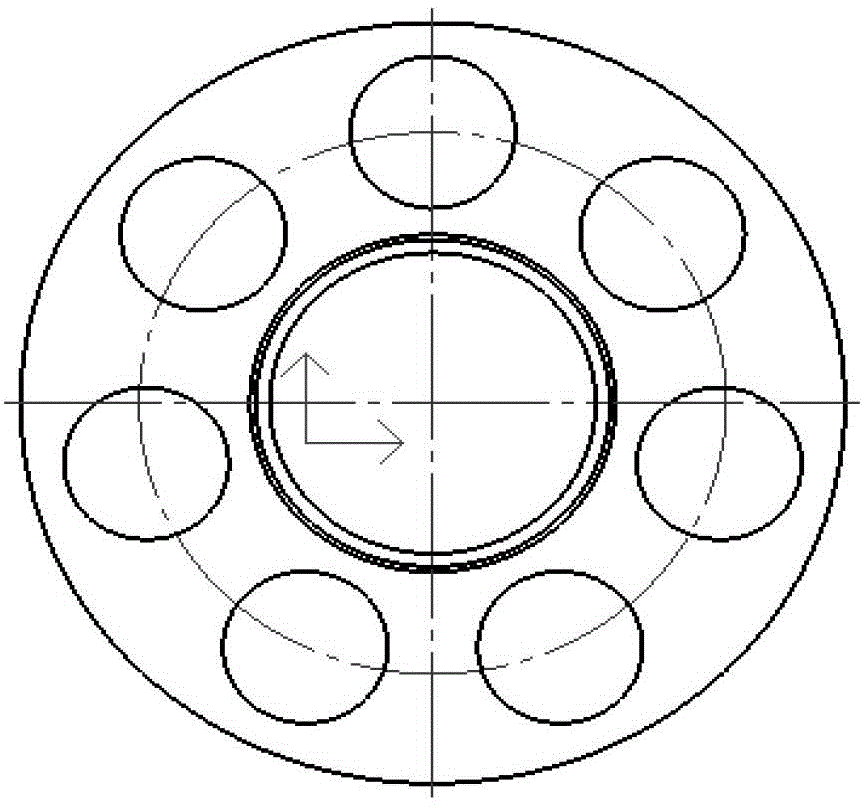

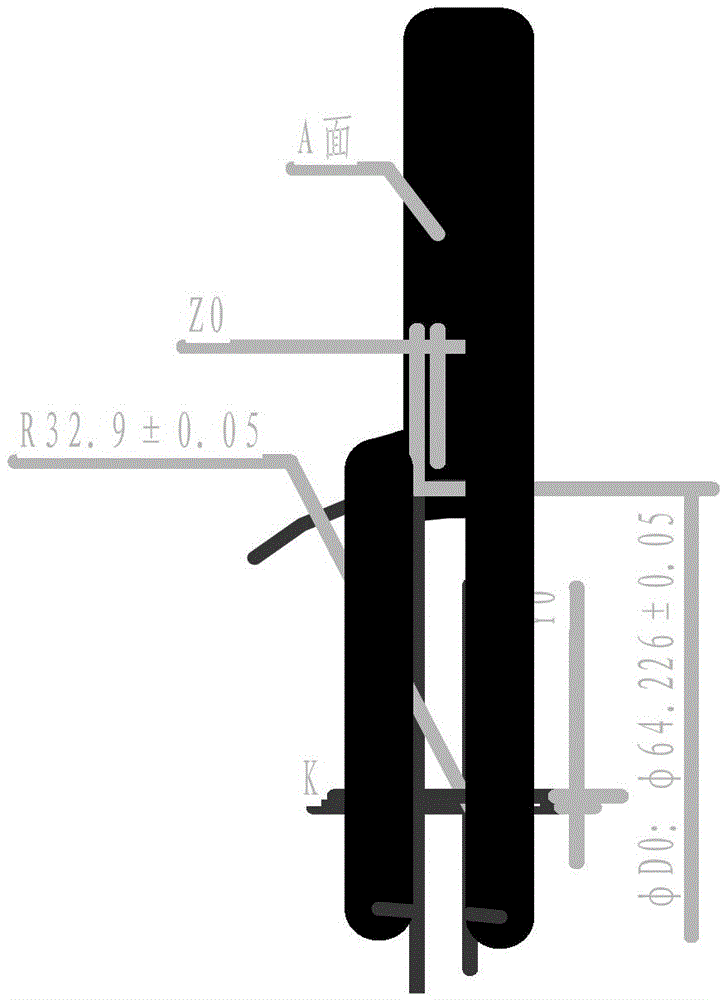

[0027] see image 3 , the present invention provides a measuring tool for inner sphere section circle diameter, which includes a base 7, a first movable measuring unit, a first data reading device 1, a second movable measuring unit, a second The data reading device 1 and the fixed measuring unit; the fixed measuring unit comprises two equal-height fixed ball heads 5; the two fixed ball heads 5 are fixedly arranged on the base 7; the mobile center of the first movable measuring unit is connected with the two fixed ball heads 5 The ball head 5 forms an isosceles triangle on the same plane; one end of the first movable measuring unit is connected with the second movable measuring unit by a spring 8; the other end of the first movable measuring unit is connected with the reading meter probe of the first data reading device 1 contact; the second movable measurement unit is connected to the first movable measurement unit by a spring 8; the second data reading device 1 rests against ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com