A multi-coated turning insert

A multi-coating and insert technology, which is applied in turning equipment, cutting tools for lathes, layered products, etc., can solve the large difference in performance between the coating and the insert substrate, large residual stress of the coating, and easy microcracks, etc. problems, to achieve excellent wear resistance, reduce the internal stress of the coating, and prevent the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

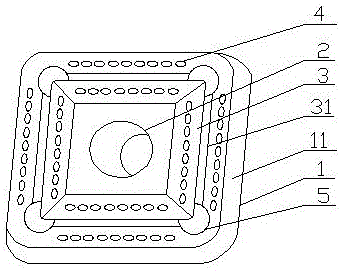

[0012] Such as figure 1 As shown, a multi-coated turning insert is composed of an insert base and a coating coated on the insert base. The insert base includes a cutter body 1 with a square cross section. The overall structure of the cutter body 1 is a cuboid. The body 1 has two upper and lower end faces and four side faces 11, and the center of the cutter body 1 is provided with a mounting hole 2, which is used to install the blade on the handle, and the upper end face of the cutter body 1 is provided with a chip breaker 3. The chip breaker 3 is surrounded by four groove edges 31 with trapezoidal longitudinal section. The four groove edges 31 correspond to the four sides 11 of the cutter body 1 respectively, and the width of the top surface of the groove edge 31 is smaller than that of the bottom surface The width of the two adjacent grooves along the outer sides of 31 is connected by an arc surface transition. This arc surface design can further strengthen the anti-fatigue a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com