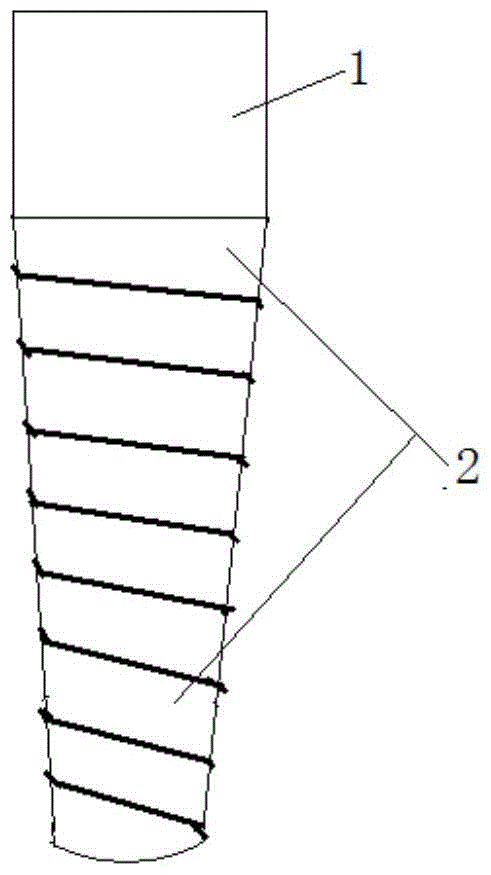

A polyetheretherketone/nanometer hydroxyapatite dental implant and its manufacturing method

A technology of nano-hydroxyapatite and polyether ether ketone, which is applied in prosthetics, medical science, coatings, etc., can solve problems such as the unreliable bonding interface between the neck of the surface structure design and the gingival tissue, and implantation failure. Avoid implant loosening, improve the success rate, and promote the effect of attachment growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] In this example, the preparation method of polyetheretherketone / nano-hydroxyapatite dental implant is as follows:

[0034] (1) The polyetheretherketone powder and nano-hydroxyapatite powder are mixed according to the mass ratio of 1:10 by mechanical blending method to obtain the polyetheretherketone / nano-hydroxyapatite composite material, and the molding machine is used Process polyetheretherketone / nano-hydroxyapatite composite materials into dental implant-like blanks;

[0035] (2) Clean the green body obtained in step (1) ultrasonically for 5 minutes in ethanol and then vacuum-dry it. Soak the neck of the green body after cleaning and drying in a fibronectin solution with a concentration of 5 μg / mL for 0.5 h and take it out. The green body after soaking treatment has an energy density of 250mJ / cm 2 0.5h of ultraviolet light irradiation, after the end of the irradiation, the surface of the body was cleaned with deionized water and dried naturally to obtain a body with...

Embodiment 2

[0040] In this example, the preparation method of polyetheretherketone / nano-hydroxyapatite dental implant is as follows:

[0041] (1) The polyetheretherketone powder and nano-hydroxyapatite powder are mixed according to the mass ratio of 4:10 and fully mixed by mechanical blending method to obtain the polyetheretherketone / nano-hydroxyapatite composite material, which is molded by a compression molding machine Process polyetheretherketone / nano-hydroxyapatite composite materials into dental implant-like blanks;

[0042] (3) immerse the green body root that step (2) obtains and be that concentration is 13g / L in the decafluoronaphthalene solution etch 0.7 hour, make the root portion surface of described green body form micron-scale porous structure, then the etched The root of the green body is placed in nano-hydroxyapatite powder to adhere a layer of nano-hydroxyapatite particles, so that the surface of the root forms a micro-porous-nano-protruded multi-level microstructure;

[...

Embodiment 3

[0046] In this example, the preparation method of polyetheretherketone / nano-hydroxyapatite dental implant is as follows:

[0047] (1) The polyetheretherketone powder and nano-hydroxyapatite powder are mixed according to the mass ratio of 7:10 by mechanical blending method to obtain the polyetheretherketone / nano-hydroxyapatite composite material, and the molding machine is used Process polyetheretherketone / nano-hydroxyapatite composite materials into dental implant-like blanks;

[0048] (2) Ultrasonic cleaning the green body obtained in step (1) in ethanol for 10 minutes and then vacuum-drying, soaking the neck of the green body after cleaning and drying in a fibronectin solution with a concentration of 60 μg / mL for 1 hour, taking out the neck, and then soaking The green body after treatment has an energy density of 350mJ / cm 2 1h of ultraviolet light irradiation, after the irradiation, the body surface was cleaned with deionized water and dried naturally to obtain a body with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com